Inventory analytics plays a vital role in today’s e-commerce world. Businesses facing volatile demand fluctuations generally utilize inventory analytics in demand forecasting to better enable efficient stocking. Furthermore, inventory management analytics is used to optimize inventory levels, improve customer experience, and improve decision-making, as businesses can adapt to the dynamic and rapid nature of the online retail sector. This article will be jumping into the world of inventory analysis or analytics in inventory management, its key metrics, and the different types that are found across the business space.

What is Inventory Analysis

Inventory management analytics refers to the use of inventory data management analysis and advanced analytics techniques to optimize the management of a company’s inventory. The process involves a range of processes encompassing inventory, and supply chain operations data. These factors, used in conjunction with inventory analysis, enable companies to make more informed decisions and improve the efficiency of their inventory control.

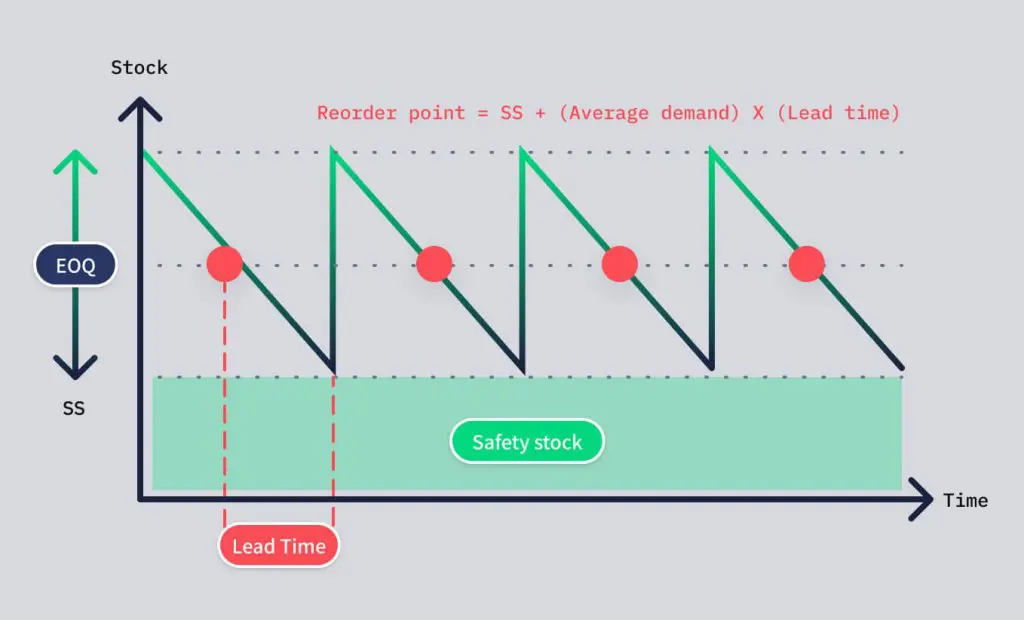

Inventory analysis is undoubtedly a fundamental component of effective stock management, using data and analytical techniques to understand and optimize various aspects of a company’s stock or inventory. Not only is this data used to determine optimal stock levels for each product by calculating the balance between having enough available stock to satisfy demand and avoiding overstocking situations, it can also provide valuable insights into the future evolution of your stock levels.

Types of Inventory Analysis

Inventory analysis can be categorized into four main types: Descriptive, Diagnostic, Predictive, and Prescriptive, with each type of inventory management analysis serving a different purpose in providing insight into optimized inventory management.

Descriptive Inventory Analysis: This method of analysis aims to provide a clear picture of historical inventory data as well as the current status of inventory. This analysis describes what has previously happened, and what is currently happening regarding inventory management, analyzing historical business data of past sales, stock levels, and lead times. Descriptive analysis is valuable for understanding the performance of prior inventory and identifying market trends and where your business falls into these.

Diagnostic Inventory Analysis: Diagnostic analysis, much like its medicinal name, is used to obtain a deeper understanding regarding the causes of inventory-related issues and performance – it diagnoses the underlying problem areas of a company. It is useful to identify the reasons behind trends or challenges. By segmenting data to identify anomalies or patterns, diagnostic analysis assists in pinpointing problem areas that could lead to issues such as stockouts or low inventory turnover.

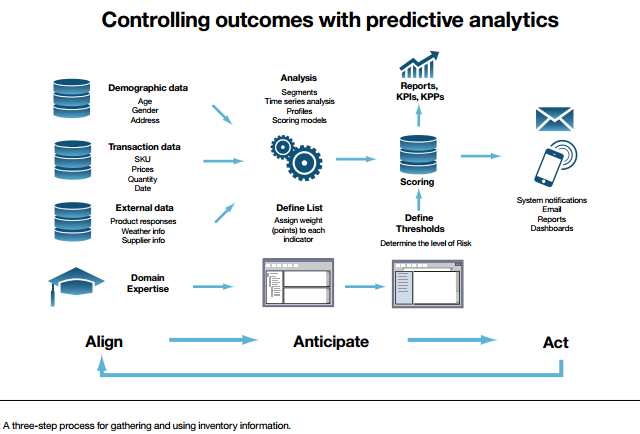

Predictive Analysis: Based firmly on demand forecasting, predictive analysis uses historical data and models to create forecasts regarding future inventory requirements and trends. This enables

businesses to anticipate, and effectively ‘predict,’ changes in supply and demand. By using past demand, seasonality of products, and external market factors data, predictive models can estimate future demand for products. This assists companies in proactively planning for future inventory requirements whilst minimizing stockouts. This form of analysis has the potential to revolutionize business operations as many business risks are mitigated due to accurate demand forecasting through accounting for both seasonality and trends. By accurately forecasting demand and supply, businesses can constantly maintain optimal inventory levels, resulting in cost reduction from lower carrying costs and freeing up working capital. Furthermore, customer satisfaction may be boosted as products should consistently be available. Supply chain disruptions can also be proactively addressed using predictive analysis by implementing measures to prevent any issues that are predicted to arise. Predictive inventory management can significantly improve business operations by optimizing stock levels and empowering data-backed decisions. This allows businesses to act more competitively and to adapt to market conditions.

Prescriptive Analysis: Another medicinal term, prescriptive analysis uses predictive insights to recommend specific actions to optimize inventory management. This analysis provides actionable recommendations for management, essentially acting as a medicine to heal the weak spot! Algorithms are implemented to determine the most optimal and cost-effective order quantities and safety stock levels, making this form of analysis valuable in making informed choices based on data.

Key Metrics and KPIs in Inventory Analysis

Inventory management data serves as the backbone for various processes used in inventory analysis. Historical sales data and market trends are essential for accurate demand forecasting, while data obtained regarding lead times, order quantities, and carrying costs contribute to calculating optimal inventory levels. Thus, it is evident that the collection of inventory management data is vital for the implementation of a successful inventory analysis system.

In particular, the inventory turnover ratio, which is the rate at which inventory is sold (calculated by dividing the cost of goods sold by the average inventory for the same period), can be a sound indicator of the efficiency of inventory. A high inventory turnover indicates efficient use of inventory, whereas a low inventory turnover may signal potential issues.

Stockout rates can also provide essential information regarding the inventory management process. The stockout rate is the percentage of items not available when needed for sale (calculated as items not in stock divided by total available items in inventory).

These, and many other key metrics can be extremely useful when performing inventory analysis.

Read more on demand planning KPIs in our blog article.

Methods and Tools for Inventory Analysis

There are various methods used in inventory analysis to categorize products based on certain criteria. The most common are ABC, HML, VED, and SDE. Let us have a look at

these:

ABC Analysis: ABC Analysis is a method of categorizing items in inventory based on their relative importance and contribution to the overall value of the company. Items are categorized into three groups, namely, A, B, and C. Category A items are high value and contribute significantly to inventory value, Category B items are moderate value and have a moderate impact on inventory value, while Category C items possess low value and do not contribute materially to the value of inventory. ABC Analysis is useful for prioritizing resource allocation.

High, Medium, Low Analysis (HML): HML Analysis categorizes items based on their monetary value. Items are simply classified into High Value, Medium Value, and Low Value. Similar to ABC Analysis, HML Analysis assists in the allocation of resources, prioritizing the High-Value items.

Valid, Essential, Desirable Analysis (VED): Straying from the value-based hierarchy, VED Analysis rather categorizes items based on their criticality and importance for production or service. It assesses whether each product or service is vital, essential, and desirable. Vital items are crucial for production and any unavailable items would have a significant impact on the production process, essential items are necessary for production, although they may have substitutes available, and desirable items are in demand but are not important for production. VED Analysis determines the level of control and attention allocated to each category of products, ensuring that there is a focus on maintaining the availability of essential products.

Scarce, Difficult, Easy Analysis (SDE): Scarce items are uncommon in the market and may face procurement challenges. Difficult items are available but may pose procurement difficulties. Easy items are readily available with ease of procurement. SDE Analysis thus categorized these items on their availability and procurement difficulty accordingly.

These methods of product categorization can be used as valuable tools for businesses to apply different control and management strategies based on the specific characteristics and relative importance of each product. Inventory management tools like Intuendi enhance efficiency through automation, provide insight into performance through reporting, streamline order processes through reliable order fulfillment, and reduce costs by optimizing inventory levels. Read our case study on how multi-dimensional ABC analysis helped this business grow at an astounding rate while maintaining a lean inventory.

Inventory Intelligence: Beyond Mere Analysis

Inventory intelligence can be defined as the use of analytics and data-backed findings through smart technologies to help provide a more holistic understanding of inventory management procedures, and how to better handle a company’s stock within the supply chain. Inventory intelligence essentially takes raw data and transforms it into actionable insights to better a company’s inventory control.

Advanced analytics involves employing sophisticated data analysis techniques that extract insights, predict trends, and optimize inventory management. Advanced analytics is used to forecast demand which assists in planning inventory stock. It can also assist in creating scorecards for suppliers, which evaluate lead times and delivery reliability in order to reduce supply chain disruptions.

Advanced inventory intelligence provides real-time monitoring that triggers alerts for low stock levels or a change in demand, allowing businesses to make proactive decisions. Combining the above with market data and industry trends, advanced analytics provide businesses with a competitive advantage as businesses can create inventory strategies driven by data and optimization.

Why is Inventory Analysis Important for Businesses?

Driven by the rapid evolution of technology over the last few decades, inventory analysis has gained poignant significance in the digital age. The expansion of e-commerce has reshaped the consumers’ experiences and demands, emphasizing the need for precise inventory management.

The abundance of accessible data is, if not the key characteristic of the digital age. Inventory analysis utilizes this data to assist businesses in making informed decisions by aligning supply chain operations with market demand. Furthermore, inventory analysis combines automation and AI integration to streamline routine tasks and reduce human errors, which empowers businesses to remain adaptable and resilient. This is supplemented by the real-time insights that inventory analytics provide.

Exploring inventory analysis tools and embracing advanced solutions can revolutionize how your business manages its inventory. There is a wide selection of tools available from basic inventory tracking to sophisticated predictive analytics and inventory optimization software. Inventory analysis will enable greater potential, a competitive edge, and adaptability.

Download our free eBook on how to maintain a lean inventory using inventory management software analytics: