As channels, markets, and consumer segments become more complex and fast-changing, companies are increasingly challenged to produce inventory forecasts and demand plans that get the right inventory to the correct location at the right time. Businesses need to be agile and responsive to the changing customer demand. Traditional methods of demand planning and forecasting, based on historical data and statistical models, are often inaccurate and unreliable, leading to excess inventory, stockouts, lost sales, and dissatisfied customers. To overcome these challenges, businesses need to adopt a more advanced and innovative approach to sense and shape demand in real-time. This approach is called demand sensing.

Demand sensing is the process of capturing, analyzing, and using real-time demand signals from various sources, such as point-of-sale data, e-commerce transactions, social media, weather, events, and promotions, to generate more accurate and timely demand forecasts. Demand sensing enables businesses to adjust their supply chain operations and inventory levels to meet the actual customer demand, rather than relying on outdated and inaccurate forecasts. Demand sensing also helps businesses to identify and exploit new opportunities, such as emerging trends, customer preferences, and market niches.

What is Demand Sensing and Why is it Important?

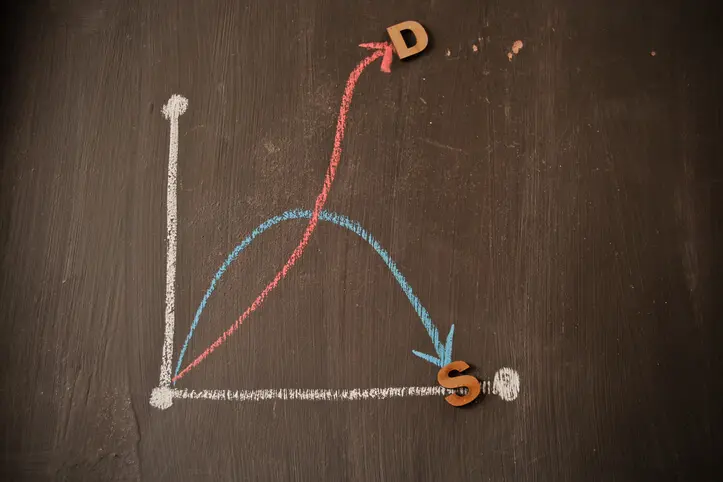

Demand sensing is a subset of demand management, which is the process of aligning supply and demand across the supply chain. Demand sensing differs from demand forecasting in that it uses real-time data and advanced analytics to generate short-term and medium-term demand forecasts, while demand forecasting uses historical data and statistical models to generate long-term demand forecasts. Demand sensing complements demand forecasting by providing more granular and accurate demand information, which can be used to fine-tune the demand forecast and optimize supply chain operations. But how has it become increasingly important in the modern-day market?

Importance of demand sensing today

Companies using demand-driven planning and demand sensing can detect market changes at least five times faster and respond three times quicker than those employing traditional inventory forecasting methods. According to a recent report sixty-one percent of best-in-class consumer products and retail companies cite demand-driven planning and demand sensing as a game-changing capability, while 85% believe this capability is growing in importance. Demand Sensing’s impact on supply chain KPIs and financial KPIs has been monumental! Demand sensing can improve the performance of key supply chain indicators, such as inventory turnover, service level, fill rate, and order fulfillment. By reducing the gap between forecasted and actual demand, demand sensing can help businesses reduce inventory costs, avoid stockouts, increase sales, and enhance customer satisfaction. According to a study by Aberdeen Group, businesses that use demand sensing can achieve up to 37% improvement in forecast accuracy, a 17% reduction in inventory, and a 14% increase in perfect order rate.

It is crucial to identify that demand sensing and demand forecasting are not mutually exclusive, but rather complementary processes that can work together to improve the overall demand management. Demand sensing can provide more accurate and timely demand information for the short-term and medium-term horizon, while demand forecasting can provide more strategic and long-term demand information. Demand sensing can also feed back into demand forecasting, by providing valuable insights and feedback on the accuracy and reliability of the demand forecast. By integrating demand sensing and demand forecasting, businesses can achieve a more holistic and balanced view of the demand, and optimize their supply chain operations accordingly. Businesses using demand-driven planning and demand sensing become much more closely linked to the market and pull-driven. They can position inventory accurately, react swiftly to real consumption levels, and underpin the success of their strategy by improving the accuracy of near-term forecasts.

Demand-driven planning and demand sensing also enhance companies’ ability to shape demand. From a marketing perspective, they can better compare the return on investment of different proposed activities because they can segregate baseline demand from the way demand behaves during promotions and events. They have a much clearer picture of which outcomes are due to different facets of promotion (10% off or 20% off; front aisle or center store; TV advertising or social media campaign) and which are due to extraneous factors (rival offers; weather conditions). From a supply perspective, demand-driven planning and demand sensing means that when companies have too much inventory, they can proactively push the market to reduce stock, and when they are low, they can remove promotions to avoid creating false expectations and disappointing customers.

How Does Demand Sensing Work?

Demand sensing is, no doubt, a complex and sophisticated process – indicating that it also takes many meticulous steps to achieve the desired outcome. Let us break down these steps into more digestible chunks:

Data Collection

The first stage of demand sensing is to collect and aggregate real-time demand data from various sources, such as point-of-sale data, e-commerce transactions, social media, weather, events, and promotions. These data sources provide rich and diverse information on customer behavior, preferences, and intentions, which can be used to sense and anticipate demand. The data collection process requires a robust and scalable data infrastructure, such as cloud computing, big data, and the Internet of Things, to handle the large volume, variety, and velocity of the data.

Data Integration

The second stage of demand sensing is to integrate and harmonize the collected data from different sources and formats and transform them into a common and consistent data model. This stage requires data integration tools and techniques, such as data cleansing, data mapping, data validation, and data standardization, to ensure the quality, accuracy, and completeness of the data. The data integration process also requires data governance and security measures, such as data policies, data ownership, data access, and data protection, to ensure the compliance, privacy, and integrity of the data.

Data Analysis

The third stage of demand sensing is to analyze and interpret the integrated data and extract meaningful and actionable insights from them. This stage requires data analysis tools and techniques, such as data visualization, data mining, data exploration, and data discovery, to explore and understand the data, and identify patterns, trends, anomalies, and correlations. The data analysis process also requires domain knowledge and business acumen, to contextualize and validate the data insights, and align them with the business objectives and strategies.

Data Modeling

The fourth stage of demand sensing is to model and simulate the data insights and generate more accurate and timely demand forecasts. This stage requires data modeling tools and techniques, such as machine learning, artificial intelligence, and optimization, to apply advanced algorithms and methods to the data, and create predictive and prescriptive models that can capture the complexity and uncertainty of the demand. The data modeling process also requires data testing and evaluation measures, such as data validation, data verification, and data feedback, to ensure the reliability, robustness, and performance of the models.

Data Reconciliation

The fifth stage of demand sensing is to reconcile and harmonize the demand forecasts generated by the data models and align them with the existing demand forecasts and plans. This stage requires data reconciliation tools and techniques, such as data consolidation, data aggregation, data adjustment, and data synchronization, to integrate and coordinate the demand forecasts from different sources and levels, and resolve any discrepancies, conflicts, or gaps. The data reconciliation process also requires data collaboration and communication measures, such as data sharing, data reporting, and data visualization, to ensure the transparency, consistency, and accessibility of the demand forecasts across the supply chain.

Data Optimization

The sixth and final stage of demand sensing is to optimize and execute the demand forecasts and adjust the supply chain operations and inventory levels accordingly. This stage requires data optimization tools and techniques, such as supply chain planning, inventory management, order management, and replenishment, to translate the demand forecasts into actionable decisions and actions, and optimize the supply chain performance. The data optimization process also requires data monitoring and control measures, such as data tracking, data auditing, and data feedback, to ensure the effectiveness, efficiency, and agility of the supply chain operations.

Technologies and Tools for Demand Sensing

With any complex system, there is likely a complex software or technological advancement that can be used to help facilitate its processes. Demand sensing is no exception. Cloud computing is the technology that enables the delivery of computing services, such as data storage, data processing, data analytics, and data modeling, over the internet, on-demand, and at scale. Cloud computing, is, therefore, used in demand sensing, by providing a data infrastructure and platform, offering high availability, scalability, flexibility, and cost-effectiveness. Cloud computing also enables the integration and collaboration of data across different sources and locations, by providing data access, data sharing, and data security.

Businesses are constantly dealing with an influx of weighty data sets, most often big data. Big data is the technology that enables the collection, integration, analysis, and modeling of large, complex, and diverse data sets, that are beyond the capacity and capability of traditional data tools and techniques. It provides the data source and input for demand sensing, by offering rich and varied information on customer demand and behavior. Big data also enables the discovery and extraction of data insights and patterns, by providing data mining, data exploration, and data discovery. Next on our demand sensing technology list is the Internet of Things (IoT) – the technology that enables the interconnection and communication of physical devices, such as sensors, cameras, scanners, and RFID tags, with the internet, and the collection and transmission of data from these devices. IoT provides the data collection and aggregation for demand sensing, by offering real-time and granular data on customer transactions, interactions, and feedback. IoT also enables the optimization and execution of demand forecasts, by providing data tracking, data monitoring, and data feedback.

With the rise of artificial intelligence, it would be a lost opportunity not to discuss its impact on demand sensing. Machine learning is the technology that enables the application of AI and algorithms to the data, and the creation and improvement of data models that can learn from the data and make predictions and decisions. Machine learning provides the data analysis and modeling for demand sensing, by offering advanced and sophisticated methods and techniques to capture the complexity and uncertainty of the demand. Machine learning also enables the generation and optimization of demand forecasts, by providing predictive and prescriptive analytics. Lastly, we have optimization. This is the technology that enables the application of mathematical models and methods to the data, and the identification and selection of the best possible solutions and outcomes. Optimization provides the data optimization and execution necessary for demand sensing, by offering optimal and efficient decisions and actions to align the supply and demand. Optimization also enables the improvement and enhancement of supply chain performance, by providing supply chain planning, inventory management, order management, and replenishment.

The Intuendi platform is probably the best example of AI and machine learning technology applied to both demand forecasting and demand sensing.

The Benefits of Demand Sensing

The benefits of demand sensing for businesses and their customers, alike, are so vast and detailed, that we decided to give each major benefit its own section. If this suits your fancy, then follow along below!

Short-term and medium-term demand accuracy

Demand sensing can improve the accuracy and timeliness of demand forecasts for the short-term and medium-term horizon, by using real-time and granular data, and advanced and sophisticated analytics. Demand sensing can reduce the forecast error and bias, and increase the forecast confidence and reliability. Demand sensing can also adapt and respond to the changing and volatile demand, and anticipate and prevent demand shocks and surprises.

Advantages for e-commerce and last-mile delivery

Demand sensing can provide advantages for e-commerce and last-mile delivery, by using real-time and granular data, and advanced and sophisticated analytics. Demand sensing can enable e-commerce businesses to understand and predict customer demand and behavior, and tailor their product offerings, prices, and promotions accordingly. Demand sensing can also enable e-commerce businesses to optimize their inventory levels, distribution networks, and delivery routes, and reduce their delivery costs, time, and carbon footprint. Demand sensing can also enhance the customer experience and satisfaction, by providing faster, cheaper, and greener delivery options, and by reducing the risk of out-of-stock, delayed, or damaged deliveries.

Managing stockouts and seasonal events

Demand sensing can help businesses to manage stockouts and seasonal events, by using real-time and granular data, and advanced and sophisticated analytics. Demand sensing can help businesses avoid stockouts, which are situations where the demand exceeds the supply, and the products are unavailable or insufficient to meet the customer demand. Stockouts can result in lost sales, dissatisfied customers, and damaged reputation. Demand sensing can help businesses to prevent stockouts, by providing more accurate and timely demand forecasts, and by enabling them to adjust their inventory levels and replenishment strategies accordingly. Demand sensing can also help businesses to cope with seasonal events, such as holidays, festivals, and special occasions, which can cause sudden spikes or drops in demand. Demand sensing can help businesses to anticipate and prepare for seasonal events, by providing more granular and timely demand forecasts, and by enabling them to adapt their product mix, pricing, and promotions accordingly.

Impact on Sales and Customer Satisfaction

Demand sensing can improve the sales and customer satisfaction of businesses, by using real-time and granular data, and advanced and sophisticated analytics. Demand sensing can increase the sales of businesses, by providing more accurate and timely demand forecasts, and by enabling them to optimize their product availability, pricing, and promotions. Demand sensing can also increase the customer satisfaction of businesses, by providing more accurate and timely demand forecasts, and by enabling them to improve their service level, order fulfillment, and delivery performance. Demand sensing can also create a positive feedback loop, where satisfied customers generate more demand signals, which in turn improve the demand sensing process, and lead to more sales and customer satisfaction.

Practical Implementation of Demand Sensing

Demand sensing is not a one-time project, but a continuous and iterative process that requires a systematic and strategic approach. Should you wish to implement demand sensing successfully in your own company, we recommend that you follow these six, crucial steps:

- Define the business objectives and scope: The first step is to define the business objectives and scope of demand sensing, such as the target markets, products, customers, and time horizons. This step helps to align the demand-sensing process with the business goals and strategies and to prioritize the most important and relevant demand signals and sources.

- Assess the data availability and quality: The second step is to assess the data availability and quality of the demand signals and sources, such as the data volume, variety, velocity, veracity, and value. This step helps to identify the data gaps and issues and to determine the data requirements and standards for demand sensing.

- Select the technologies and tools: The third step is to select the technologies and tools for demand sensing, such as the data infrastructure, data integration, data analysis, data modeling, data reconciliation, and data optimization. This step helps to choose the most suitable and effective technologies and tools for demand sensing, based on the data availability and quality, and the business objectives and scope.

- Develop and test the data models: The fourth step is to develop and test the data models for demand sensing, such as machine learning, artificial intelligence, and optimization models. This step helps to create and improve the data models that can generate more accurate and timely demand forecasts and to validate and verify the data models using historical and simulated data.

- Deploy and execute the demand forecasts: The fifth step is to deploy and execute the demand forecasts generated by the data models, and to adjust the supply chain operations and inventory levels accordingly. This step helps to translate the demand forecasts into actionable decisions and actions and to optimize the supply chain performance.

- Monitor and control the demand sensing process: The sixth and final step is to monitor and control the demand sensing process and to measure and evaluate the results and outcomes. This step helps to track and audit the demand sensing process and to provide data feedback and improvement suggestions.

Demand Sensing Real Successes Case Studies

Demand sensing has been successfully implemented by various businesses across different industries and sectors, such as consumer goods, retail, manufacturing, and pharmaceuticals. But don’t just take our word for it, below lies a number of case studies that highlight real-life success stories of demand sensing implementation and activation:

Procter & Gamble (P&G) is a multinational consumer goods company that produces and sells a wide range of products, such as beauty, health, personal care, and household products. P&G implemented demand sensing to improve its demand forecasting and supply chain planning, by using real-time data from point-of-sale, e-commerce, and social media, and by applying advanced analytics and machine learning. As a result, P&G achieved up to 50% improvement in forecast accuracy, 10% reduction in inventory, and 17% increase in service level.

We all know the famous retail corporation, Walmart, and even their size and scale company benefitted from implementing demand sending. When they included demand sensing to optimize their inventory management and replenishment, by using real-time data from point-of-sale, e-commerce, and RFID tags, and by applying artificial intelligence and optimization, Walmart achieved up to 30% reduction in out-of-stock, 15% reduction in inventory costs, and 20% increase in sales. There is also the example of Intel. Intel is a multinational technology company that produces and sells microprocessors, chipsets, and other computer components. Intel implemented demand sensing to enhance its demand forecasting and supply chain planning, by using real-time data from point-of-sale, e-commerce, and social media, and by applying machine learning and optimization. As a result, Intel achieved up to 40% improvement in forecast accuracy, a 20% reduction in inventory, and a 15% increase in customer satisfaction.

Challenges and Criticisms

Demand sensing, unfortunately, is not without challenges and criticisms. However, we have compiled a list in hopes that these issues might become easier to identify, and thus, easier to manage and fix. It requires high-quality and high-availability data from various sources, which can be challenging to collect, integrate, and analyze, due to data issues such as incompleteness, inconsistency, inaccuracy, and irrelevance. Demand sensing also requires data governance and security measures, to ensure the compliance, privacy, and integrity of the data. Additionally, demand sensing requires complex and costly technologies and tools, such as cloud computing, big data, Internet of Things, machine learning, artificial intelligence, and optimization, which can be difficult to implement, maintain, and upgrade, due to technical issues such as compatibility, scalability, reliability, and performance. Demand sensing also requires technology expertise and skills, to operate and utilize the technologies and tools effectively and efficiently. Lastly, demand sensing requires organizational alignment and change, such as the alignment of the business objectives and strategies, the collaboration and communication of the supply chain partners, and the adoption and adaptation of the demand sensing process and outcomes. Demand sensing also requires organizational culture and mindset, to embrace and support the demand sensing process and outcomes.

The Future of Demand Sensing

Demand sensing is not a static and stagnant process, but rather a dynamic and evolving one that will continue to develop and improve in the future. Some of the emerging trends and future developments of demand sensing include more data sources and signals, more sophisticated analytics and models, more integration and collaboration across the supply chain, more automation and intelligence within the process, and finally, more impact and value for businesses and their customers.

Today, the massive data generation combined with powerful analytics, algorithms, and artificial intelligence (AI), much like that that we see from Intuendi, as well as cheap data storage, make demand sensing possible. Whereas before, we merely had to stick with the more straightforward demand forecasting. Given the inconceivable amounts of data that nearly every organization, across all industries, produces every day, the emphasis is shifting from “big data” to “smart data.” Demand sensing is perfect for big data or smart data because big data affects almost every industry and every job. More industrial, office-based, and household devices – an estimated “50 billion by 2020” – connect to the Internet, creating the pervasive Internet of Things (IoT). Every organization, regardless of size or industry, must embrace big data and analytics to compete and thrive. Now, every business can gain valuable customer insight and track inventory – whether tangible or intangible – in useful, relevant detail and with the power of Intuendi and demand sensing start to see where the business is going

Conclusion

Demand sensing is a powerful and innovative approach to sense and shape demand in real time, by using real-time data and advanced analytics. Demand sensing can improve the accuracy and timeliness of demand forecasts, and optimize the supply chain operations and inventory levels, to meet the actual customer demand. Demand sensing can also provide various benefits for businesses and customers, such as increasing sales and customer satisfaction, reducing inventory costs and stockouts, and enhancing e-commerce and last-mile delivery. Demand sensing can also help businesses to cope with the changing and volatile market, and to identify and exploit new opportunities.

Demand sensing is not a simple and easy process, but a complex and challenging process that requires a systematic and strategic approach. Demand sensing also requires high-quality and high-availability data, complex and costly technologies and tools, and organizational alignment and change. Demand sensing also faces challenges and criticisms, such as data quality and availability, technology complexity and cost, and organizational alignment and change. It is not a one-time project, but a continuous and iterative process that will continue to develop and improve in the future. Demand sensing will leverage more data sources and signals, apply more advanced and sophisticated analytics and models, enable more integration and collaboration across the supply chain, achieve more automation and intelligence in the demand sensing process, and create more impact and value for businesses and customers. Demand sensing is a key component of demand management and a critical factor for supply chain success. Demand sensing is the future of demand forecasting and the future of supply chain management.