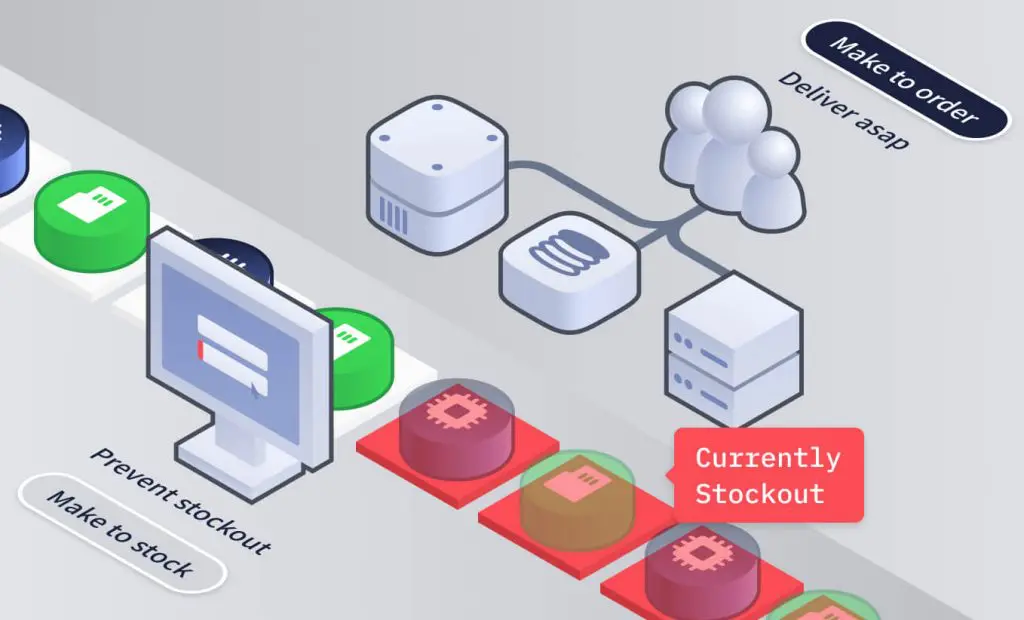

Although many companies adopt some kind of a mixed strategy, we can distinguish two common production environments:

Make-to-Stock (MTS), also known as a “push” system. Demand is estimated, through more or less sophisticated tools, and orders (for production or for external procurement) are issued in order to optimize the overall costs while trying not to under– or over–stock.

Make-to-Order (MTO), also known as a “pull” system. Demand is perfectly known, as orders are issued only after customers have signed a purchase contract that specifies what, how much, when, and where. A few variants to the basic Make-to-Order approach also exist called Assemble-to-Order, and Engineer-to-Order.

Not every kind of business can be efficiently run under any one of the two systems above. MTS systems are well suited for situations in which demand forecasting, possibly based on historical demand data as well as on exogenous variables, is available. Although it is well known that forecasting is inevitably imprecise, the effect of an incorrect forecast can be either excess stock or under-stock. In the first case, costs increase, because of inventory-related expenses (management, refrigeration, insurance, surveillance) of perishability and obsolescence, or even just for the fact that some amount of money was used to produce stock, while it might have been used more efficiently in another way. On the other hand, understock is extremely negative, as it generates customer dissatisfaction and low service quality; in highly competitive markets, even a single stock-out might cause the loss of a customer. On the other hand, it seems that MTO systems can avoid these disadvantages. As production is demand-driven, there is apparently no need for any inventory and, as a consequence, waste is avoided. When speaking of waste, I mean both final products and capital investment. There is no danger of over- or under-stock. Moreover, as production is started after an order has been received, it is perfectly possible to produce highly customized items to match customer needs. Even “mass customization” becomes possible, as production starts after the precise requirements of each customer are received. This has also a very positive effect on customer satisfaction. MTO is a frequently adopted policy in many companies, from pharmaceuticals to perishable items (e.g., fresh food) or fashion. No need for forecasting, no waste, no customer dissatisfaction. . .

All perfect then? Not exactly. . . According to the no-free-lunch-theorem, these (sometimes apparent) advantages come at a cost and with some risk.

Disadvantages of MTO

Although MTO production is driven by demand, usually production needs basic components to be assembled, a suitable workforce to produce, and machines to prepare and assemble finished products. So, even without uncertainty in demand, a production manager has to face all of the usual difficult strategic and tactical decisions on Material Requirement Planning, Capacity Planning, Workforce Management, . . . Moreover, demand forecasting is needed, for the inventory of basic components.

Even in perishable production systems like the production of fresh “pasta”, an inventory of flour, eggs, and salt, needs to be managed. This comes with all the usual costs and risks of over and under-stock. If you are not capable of managing demand, even in an MTO environment like this one, it might happen that we cannot deliver a customer order on time as, for example, we do not have enough eggs available and keeping an inventory of eggs, requires a demand forecast for future purchase orders of fresh pasta. In practice: we don’t start production of pasta until we receive a customer order. But when the order is received, we must be ready. Thus optimal inventory management is, again, a fundamental step in running an efficient MTO system. A classical case study for MTO approaches is Dell, the computer manufacturing company known to be the first one to introduce highly customized configurations. It can be easily understood that a company like Dell, in order to be ready to satisfy customer orders with a short lead time, needs large inventories of electronic components; more so these days, when there is a worldwide shortage of chips. The Dell case gives me the possibility to cite another difficulty with MTO systems: lead time.

Customization comes at a price: longer production times. This in turn generates customer dissatisfaction. In the e-commerce era, customers are getting more and more used to a chose-order-pay-receive cycle which is every day shorter. Delivery within 24 hours has become a standard, even for sophisticated technological products. In order to be able to satisfy this new requirement, companies are re-introducing anticipative production, or, in our terminology, MTS systems. At least, they adopt a Make-to-Stock policy for frequently sold configurations or for “almost ready” configurations which might accommodate for a limited number of options.