The supply chain world is seeing an increased demand for improved planning of perishable inventory and how to manage it. Perishable inventory can be referred to products, goods, or stock that deteriorate in value in direct proportion to their expiry date. In layman’s terms – goods with a short shelf-life that lose their value after their expiration date has passed. Understanding a term can be aided through the explanation of the opposite: non-perishable goods. Non-perishable goods are products that do not spoil or decay over time. They have a longer shelf-life compared to perishable goods and are generally more durable in nature, enabling them to be stored for extended periods without risk of spoilage or degradation in quality.

What is Inventory Shelf-Life?

However, perishable supplies are not confined to the food produce world, as this category of stock can be found in many other industries. Most, if not all, business sectors use perishable inventory – it might just take a longer period for this stock to reach its product’s shelf-life. Shelf-life, expiration-date or expiry-date are all interchangeable terms for how long a product can be used before it spoils and is deemed obsolete. Perishable goods become more ‘perishable,’ when the time it takes to transition from one period (days, weeks, months, years) to the next is shorter. Cosmetics and pharmaceuticals have strict shelf-lives as human use after spoilage can lead to potentially harmful situations.

Perishable Goods in Service

Perishable goods are also found in different service industries, often needing replenishments. Electronics, batteries and computer hardware fall under the perishable inventory heading, as many of these items become obsolete after their shelf life has been reached. Even something as simple as a concert ticket or a hotel booking can be referred to as perishable supply, as they expire after use. Whatever industry, be it goods or service, particular perishable items belong to, it is imperative that they receive careful management to minimise waste and loss.

Examples of Perishable Items

Included below is a wide range of perishable stock examples, including perishable food and perishable items used in services.

- Meat – poultry, fish,

- Eggs

- Dairy products

- Raw produce – fruit and vegetables

- Cooked leftovers

- Pharmaceuticals

- Cosmetics

- Batteries

- Electronics

- Event Tickets

Perishable Inventory Tools

The risk in handling perishable goods is that unsold expired products hold no value, resulting in the loss of entire investments. In this article, we will be looking at the kinds of perishable inventory as well as the tools you can implement to track and store this stock. Perishable goods management has thus become a huge area of consideration for businesses across the world. At its core, perishable inventory tracking follows similar structures to that of any non-perishable goods – however, there are often more considerations and costs necessary for its success.

FEFO Removal Strategy and FIFO

Time is the central factor when handling perishable goods, thus calling upon time-sensitive strategies when managing when and how it is stocked. The FEFO (First Expired, First Out) Removal Strategy is a technique almost entirely explained by its name – the products that are closest to their expiry date are sold first to the market. The benefits of the FEFO Removal Strategy is that there is less wastage, labour costs are reduced through having less spot-checks, and it gives sellers a larger opportunity to sell each unit before they extend their shelf-life.

Alternatively, the similarly-named but slightly different FIFO (First In, First Out) method can be implemented. This tracking method dictates that the first batch of stock reaching the warehouse should be the first leaving the warehouse to be sold on the market. The benefits to both FEFO and FIFO strategies are similar, and are optimised when the strategies are used together. They work off the same logic that the perishable items that are first to arrive at the warehouse are also first to expire. With the correct quality control, this duo can help cut warehousing and labour costs, and can reduce the amount of inventory passing its expiry date.

Perishable Inventory Software

The bulk of perishable inventory management can be deduced to the weighty effort of careful planning and scheduling. Perishable stock levels need regular monitoring to avoid running into the spoilage, wastage and stock-level issues. This can be achieved through the use of Perishable Inventory Software. This software is designed to track which products are nearing their expiration date. Because stock-levels are a crucial element of handling perishable goods, this software can additionally help automate the ordering process. Additionally perishable inventory software aids in demand forecasting, allowing businesses to accurately predict future demand for their perishable products. Perishable Inventory Software can also be used in conjunction with other types of software, from accounting and supply chain management to POS-systems.

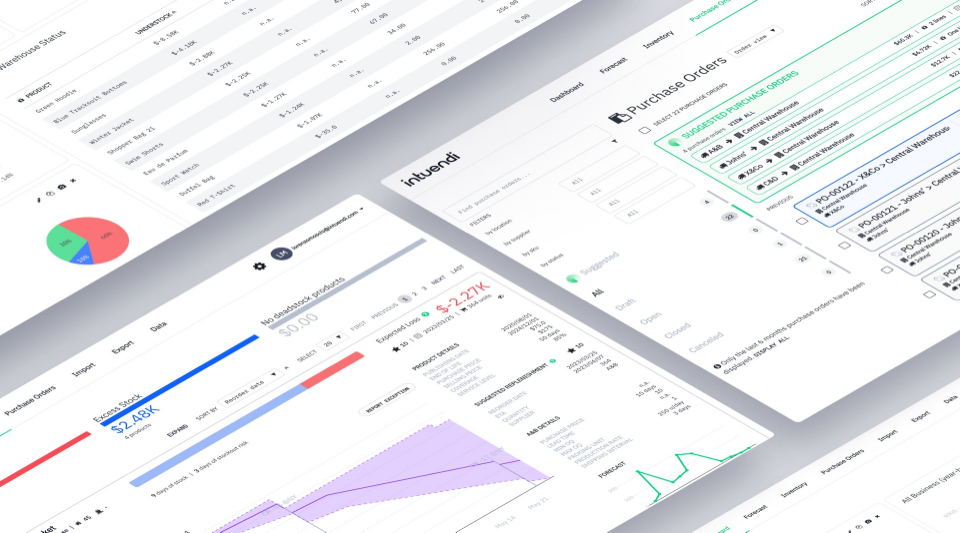

Intuendi Inventory Tool

If you find that perishable inventory software is what your business needs in order to optimise the tracking process of perishable stock, we highly recommend making use of Intuendi’s Perishable Inventory Optimisation Software. Visit the page Intuendi Inventory Management Software to see why we recommend our AI driven tool.

Would you like to learn more about how Intuendi implements demand planning for items with a shelf life? Request a free demo today.

Traditional Spreadsheet

While investing in inventory management software seems like the most obvious option when handling perishable stock, the consideration that smaller businesses would not able to handle this cost is often overlooked. Not all is lost, as there are more cost-effective alternatives, such as the use of traditional spreadsheets. For these smaller businesses, using a traditional spreadsheet serves as a cheaper, but efficient, tracking method. Spreadsheets are widely available tools that can be used for inventory tracking. The challenge regarding spreadsheets, however, is that they take time to maintain and are subject to human error. Nonetheless, with meticulous monitoring, the use of traditional spreadsheets can prove to be a great option for low-budget companies.

Selling Short-Dated Products

Short-dated products are perishable goods that are nearing their expiration date. Adding discounts onto short-dated products is a top strategy for perishable stock management, as these attract price-sensitive customers. The sale of short-dated products directly results in less spoilage and wastage of perishable stock, and indirectly, lowers revenue losses. Additional benefits of selling short-dated products is the tracking needed to identify short-dated products provides insights into consumer-demand patterns, allowing stockists to determine when customers will be buying what products. This provides the opportunity to adjust order and storage strategies to better align with customer demand.

Why is Perishable Inventory Important?

What can be firmly concluded from the above tips, tools and strategies is that effective perishable inventory management, tracking and planning can directly result in huge savings for businesses. All the afore-mentioned strategies aid in the reduced risk of spoilage, reducing losses, the improvement of inventory accuracy, and ultimately allow for the smooth-running of perishable inventory tracking. Your company, be it a small business or large corporation, will certainly benefit from efficient perishable inventory management.