There are many expenses incurred when holding inventory in storage – the inventory carrying costs. These are made up of many costs such as capital, storage, administrative, security, and more. With so many things costing a business money, it goes without saying, the importance of calculating these costs is essential for optimal utilization of a company’s financial resources. This informative article will provide you with all the need-to-know basics when it comes to the topic of inventory carrying costs. We’ll be looking at what these costs are, how to calculate them, why they are important, and the many ways to help reduce them.

What is Inventory Carrying Cost

Inventory carrying cost, also known as inventory holding cost, is the total cost of owning and storing inventory over any span of time. It includes the capital tied up in inventory as well as the costs involved in maintaining the inventory, as well as the risks associated with storing it such as theft and spoilage. When it comes to inventory management, inventory carrying costs are a key factor affecting order quantity and optimal inventory levels. Holding excess inventory is wasteful if the inventory carrying costs are high, so the goal is always to minimize these costs without affecting turnover time. However, low inventory carrying costs mean a company can hold extra inventory to meet demand and avoid stockouts, which is beneficial.

Detailed Analysis of Inventory Carrying Costs

There are five main components that make up inventory carrying costs, with each being influenced and affected by different variables and factors. Let’s take a look at each one in more detail.

Capital Cost

Capital cost is the largest component of the total inventory carrying cost, making up roughly 40% to 60% of the total. It is the cost of the money invested in inventory, also known as the opportunity cost of inventory. This is because that capital could be making money if it were invested in stocks or bonds, instead of being tied up in inventory. Capital cost can be calculated by multiplying the average inventory value by the annual interest rate or the cost of capital. The average inventory value can be estimated by dividing the sum of the beginning and ending inventory values by two, or by using the economic order quantity (EOQ) formula. The annual interest rate or the cost of capital can be obtained from the market or the company’s financial statements.

For example, suppose a company has an average inventory value of $100,000 and an annual interest rate of 10%. The capital cost of inventory is:

Capital Cost = Average Inventory Value x Annual Interest Rate Capital Cost = $100,000 x 0.10 Capital Cost = $10,000

This means that the company is losing $10,000 per year by holding inventory instead of investing the money elsewhere.

Storage Costs

Storage costs make up an estimated 10% to 25% of the total inventory carrying cost. These costs are made up of how much you pay for security, rent, utilities, etc, of the premises you store your inventory in. This cost varies according to the size, location, etc, of the premises, as well as the type, quantity, etc, of your inventory. Storage costs can be calculated by multiplying the storage cost per unit of space by the space occupied by inventory. The storage cost per unit of space can be obtained from the lease agreement or the market price. The space occupied by inventory can be estimated by multiplying the number of units by the volume or weight per unit, or by using the cube per order index (COI) formula.

For example, suppose a company pays $5 per square foot per month for renting a warehouse and has 10,000 units of inventory that occupy 0.5 cubic feet each. The storage cost of inventory is:

Storage Cost = Storage Cost per Unit of Space x Space Occupied by Inventory Storage Cost = $5 x 10,000 x 0.5 Storage Cost = $25,000

This means that the company is spending $25,000 per month for storing inventory.

Inventory Service Costs

Inventory service costs make up about 5% to 15% of the total inventory carrying cost. Inventory service costs are made up of labor, equipment, handling, labeling, packaging, etc. These costs can be affected by the complexity, frequency, and quality standards of the inventory. Inventory service costs can be calculated by multiplying the service cost per unit of inventory by the number of units. The service cost per unit of inventory can be derived from the labor and overhead rates, or from the activity-based costing (ABC) method. The number of units can be obtained from the inventory records or the inventory turnover ratio.

For example, suppose a company spends $0.50 per unit of inventory for handling, packaging, labeling, inspecting, testing, and audits, and has 10,000 units of inventory. The inventory service cost is:

Inventory Service Cost = Service Cost per Unit of Inventory x Number of Units Inventory Service Cost = $0.50 x 10,000 Inventory Service Cost = $5,000

This means that the company is spending $5,000 to provide services to inventory.

Inventory Risk Costs

Inventory risk costs make up between 5% to 10% of the total inventory carrying cost. These costs include any potential losses of inventory, whether due to fire, theft, spoilage, or obsolescence. It also includes insurance, markdowns, write-offs, etc. Inventory risk costs can vary according to the shelf life or value of the inventory, as more valuable inventory requires more security. Inventory risk costs can be calculated by multiplying the risk cost per unit of inventory by the number of units. The risk cost per unit of inventory can be estimated by using historical data, the expected loss rate, or the insurance rate. The number of units can be obtained from the inventory records or the inventory turnover ratio.

For example, suppose a company has a risk cost of $0.10 per unit of inventory due to obsolescence, deterioration, spoilage, shrinkage, theft, fire, flood, or other disasters, and has 10,000 units of inventory. The inventory risk cost is:

Inventory Risk Cost = Risk Cost per Unit of Inventory x Number of Units Inventory Risk Cost = $0.10 x 10,000 Inventory Risk Cost = $1,000

This means that the company is losing $1,000 due to inventory risks.

Operational and Administrative Costs

Operational and administrative costs make up about 5% to 10% of the total inventory carrying cost. These costs include all the costs of managing the inventory, such as ordering, receiving, analyzing, etc, as well as the costs of labor, transportation, and software. The costs are all influenced by the efficiency, accuracy, and frequency of the inventory process. Operational and administrative costs can be calculated by multiplying the operational and administrative cost per unit of inventory by the number of units. The operational and administrative cost per unit of inventory can be derived from the labor and overhead rates, or from the activity-based costing (ABC) method. The number of units can be obtained from the inventory records or the inventory turnover ratio.

For example, suppose a company spends $0.20 per unit of inventory for ordering, receiving, recording, tracking, reporting, and analyzing, and has 10,000 units of inventory. The operational and administrative cost is:

Operational and Administrative Cost = Operational and Administrative Cost per Unit of Inventory x Number of Units Operational and Administrative Cost = $0.20 x 10,000 Operational and Administrative Cost = $2,000

This means that the company is spending $2,000 on managing and administering inventory.

Calculating Inventory Carrying Costs

To calculate the total inventory carrying cost, we need to add up all the components discussed above. The formula for inventory carrying cost is:

Inventory Carrying Cost = Capital Cost + Storage Cost + Inventory Service Cost + Inventory Risk Cost + Operational and Administrative Cost

Using the example values from the previous sections, the inventory carrying cost is:

Inventory Carrying Cost = $10,000 + $25,000 + $5,000 + $1,000 + $2,000 Inventory Carrying Cost = $43,000

This means that the company is spending $43,000 per year for holding and maintaining inventory.

To express the inventory carrying cost as a percentage of the average inventory value, we need to divide the inventory carrying cost by the average inventory value and multiply by 100. The formula for inventory carrying cost percentage is:

Inventory Carrying Cost Percentage = x 100

Using the example values from the previous sections, the inventory carrying cost percentage is:

Inventory Carrying Cost Percentage = x 100 Inventory Carrying Cost Percentage = 43%

This means that the company is spending 43% of the average inventory value on holding and maintaining inventory.

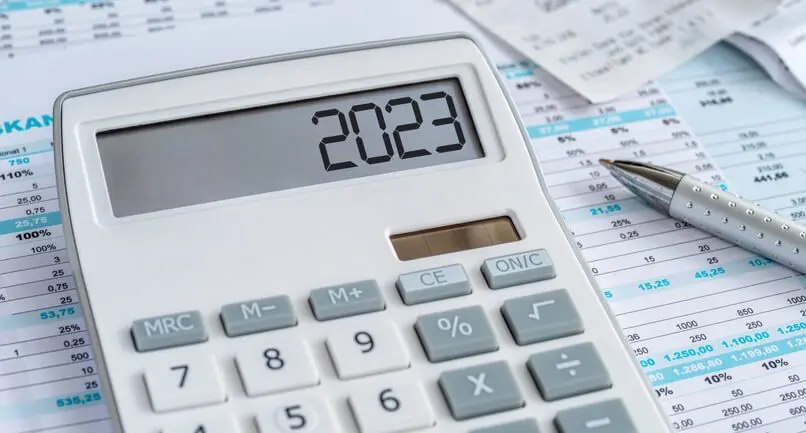

The importance of keeping the inventory carrying cost percentage as low as possible can not be emphasized enough, because the higher the cost, the lower the profits and liquidity of a business will be. While the costs can vary due to market conditions, the product, or the industry, it can always be kept lower with close monitoring and control.

Financial Impact of Carrying Costs

We have already established that inventory carrying costs have a huge effect on the financial health of a business, so why not delve deeper into the different situations in which this can occur?

Income Statement: Inventory carrying costs reduce the gross profit and the net income of a company. They are part of the cost of goods sold (COGS), which is the direct cost of producing or purchasing the goods sold by a company. The higher the inventory carrying costs, the lower the gross profit margin and the net profit margin. For example, suppose a company has a revenue of $200,000, a COGS of $100,000 (including $43,000 of inventory carrying costs), and an operating expense of $50,000. The gross profit is:

Gross Profit = Revenue - COGS Gross Profit = $200,000 - $100,000 Gross Profit = $100,000

The gross profit margin is:

Gross Profit Margin = x 100 Gross Profit Margin = x 100 Gross Profit Margin = 50%

The net income is:

Net Income = Gross Profit - Operating Expense Net Income = $100,000 - $50,000 Net Income = $50,000

The net profit margin is:

Net Profit Margin = x 100 Net Profit Margin = x 100 Net Profit Margin = 25%

If the company could reduce its inventory carrying costs by 10%, the COGS would be $90,700, the gross profit would be $109,300, the gross profit margin would be 54.65%, the net income would be $59,300, and the net profit margin would be 29.65%. This shows how inventory carrying costs can affect the profitability of a company.

Balance Sheet: Inventory carrying costs increase the inventory value and the total assets of a company. They are part of the current assets, which are the assets that can be converted into cash within a year. The higher the inventory carrying costs, the higher the current ratio and the working capital. However, this does not necessarily mean that the company is more liquid or solvent. In fact, inventory carrying costs can also increase the inventory turnover and the day’s sales of inventory (DSI), which are measures of how efficiently a company manages its inventory. The higher the inventory turnover and the lower the DSI, the better.

Cash Flow Statement: Inventory carrying costs decrease the cash flow from operations and the free cash flow of a company. They are part of the changes in working capital, which are the changes in the current assets and liabilities that affect the cash flow. The higher the inventory carrying costs, the lower the cash flow from operations and the free cash flow. For example, suppose a company has a net income of $50,000, a depreciation of $10,000, an increase in inventory of $10,000, and a capital expenditure of $20,000. The cash flow from operations is:

Cash Flow from Operations = Net Income + Depreciation - Changes in Working Capital Cash Flow from Operations = $50,000 + $10,000 - $10,000 Cash Flow from Operations = $50,000

The free cash flow is:

Free Cash Flow = Cash Flow from Operations - Capital Expenditure Free Cash Flow = $50,000 - $20,000 Free Cash Flow = $30,000

If the company could reduce its inventory carrying costs by 10%, the increase in inventory would be $9,000, the cash flow from operations would be $51,000, and the free cash flow would be $31,000. This shows how inventory carrying costs can affect the cash flow of a company.

Intangible Costs of Carrying Costs

Not all inventory carrying costs can be measured, yet they can still have a negative effect on the reputation of a company when it comes to customer satisfaction and a competitive advantage. Loss of sales is one type of intangible cost. If you hold excess inventory you may struggle to sell all the items, simply because the items may have become stale, or a newer product may have been launched that the customers might prefer to purchase. This can negatively influence your revenue. A second type of unquantifiable cost is customer dissatisfaction. Holding inventory can result in damaged or obsolete products. If a customer were to receive an old or expired product it could damage the image of the business. A third example of a cost that is impossible to measure is the lack of flexibility. When a business holds too much inventory, it may struggle to adapt to market trends and technological advancements, which will reduce its flexibility and innovation. All of these would result in the loss of customers, thereby affecting profits.

Why is Calculating Carrying Costs Crucial?

Given the significant ways that inventory carrying costs can impact the financial health of a business, it is crucial to monitor and calculate these costs regularly. In doing so you can achieve three very important things. Firstly you can optimize inventory levels, because knowing the carrying costs will help you determine the optimal inventory level and order quantity, thereby minimizing the total inventory cost. Secondly, you can improve inventory management. Knowing the inventory carrying cost will help you improve the various aspects of inventory management such as inventory replenishment, inventory classification, and inventory valuation. The third aspect that can be improved significantly by knowing your inventory carrying costs is enhanced financial performance. Knowing the cost will show you where you can reduce the inventory carrying costs, which will enhance efficiency, profitability, liquidity, and cash flow, which are all financial performance indicators. This will make the company more competitive in the market.

Factors Influencing Carrying Costs

There are several internal and external factors that can influence inventory carrying costs. Let’s discuss the four largest factors in more detail.

Safety Stock

Safety Stock is the reserve or buffer inventory a company keeps to prevent stockouts in times of unexpected higher demand. A business needs to balance the trade-off between the extra costs of carrying more inventory, and the risk of losing sales and customers if they run out of stock. This will help them determine an optimal safety stock level, while also minimizing total inventory costs. The second factor is Cyclical or Seasonal Demand.

Cyclical or Seasonal Demand

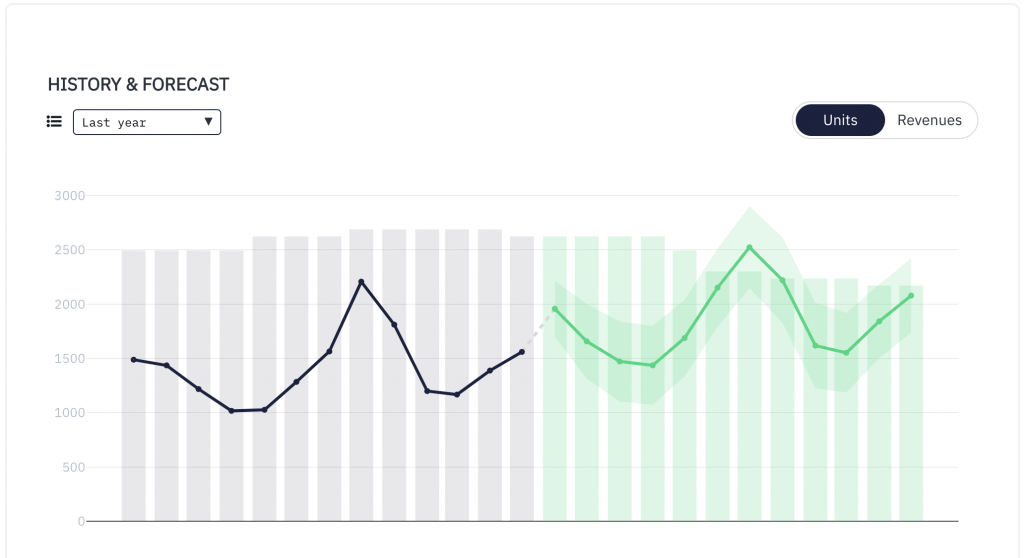

Demand fluctuates considerably due to the weather, during the holidays, etc. During these times inventory levels need to be adjusted to accommodate the increased demand. This causes increased inventory carrying costs. During quieter periods there is less inventory demand, which means decreased carrying costs. It is important to forecast the seasonal or cyclical demand accurately to avoid unnecessary holding costs, as well as stockouts.

In-transit Inventory

The third factor is the In-transit Inventory. This is also known as pipeline inventory and refers to any inventory that is in the process of being transported from the warehouse to the suppliers, or from the supplier to the customer. A company needs to balance the trade-off of the risk, and the administrative and operational costs, with the benefit of a shorter lead time between receiving orders. They must also be sure to select the optimal frequency, transportation mode, and route, in order to keep costs to a minimum. And lastly, we have Dead or Obsolete Inventory.

Dead or Obsolete Inventory

Also known as unsalable inventory, this refers to inventory that is no longer sellable, due to product defects, changes in customer preferences, and technological advancements. This inventory takes up valuable space while tying up capital, and still requires administration, which all increases costs. It also reduces inventory turnover, so it is important for a company to write off obsolete inventory, and maintain a fresh and updated inventory.

Strategies for Reducing Carrying Costs

The thought of all these costs can be quite intimidating, but fret not, as there are many available strategies that a company can implement to reduce inventory carrying costs, by minimizing inventory and increasing inventory turnover! Let us first cover the tips and techniques one can employ to help minimize inventory:

Just-in-time Inventory(JIT) is a technique that helps reduce inventory carrying costs by only ordering and receiving inventory when it’s needed. While this reduces operational costs and uses less space, it also increases the risk of stockouts and supply uncertainties. For this reason, the JIT method would only be suitable if you have a really good level of coordination and cooperation with your suppliers. Your forecasting and inventory would also need to be very accurate.

Vendor-managed Inventory (VMI) is a technique where the duty of managing inventory is transferred from the buyer to the supplier. VNI helps reduce inventory carrying costs for the buyer by no longer having ordering, receiving, and tracking costs. The buyer has to be able to trust that the supplier will optimize the inventory level as well as the replenishment frequency. This technique requires clear information sharing as well as consistent performance measures.

Drop-shipping is a technique that differs completely from the others, in that the buyer holds no inventory at all. This is because the supplier ships directly to the customer on the buyer’s behalf. No inventory carrying costs is a huge saving, but the downside of this technique is that the buyer has very little control over the product’s quality and delivery. This means that the buyer will have to rely heavily on the service and performance of the supplier.

However, in order to lower one’s inventory carrying costs, reducing the amount of one’s inventory is not the only mechanism one can put to use. Speeding up inventory turnover time is another strategy used to reduce inventory carrying costs, with several ways to increase the turnover speed!

Demand Management is a manipulating method used to shift the demand for a product or service. A company can use promotions or pricing to stimulate demand, thereby increasing sales volumes and speeding up inventory turnover. It can also use aggregation techniques to reduce the demand for its products if there are supply shortages. This helps them avoid disappointing customers.

Supply Chain Integration can speed up inventory turnover by aligning all the partners in the supply chain, through an integrated flow of information, materials, and finances. Using radio frequency identification (RFID) could improve the information flow, cross-docking consolidation could improve the material flow, and payment terms or discounts to improve the financial flow. Read more on integrated supply chains.

Lean Manufacturing is a philosophy aimed at reducing waste and increasing value in the production process. This is achieved by reducing defects, transportation, processing, and overproduction. Lean manufacturing can speed up inventory turnover by using three things: improving quality using the 5S method, improving efficiency by using value stream mapping, and improving flexibility by using rapid prototyping.

And, of course, this section would not be complete without redesigning and reutilizing warehousing space in order to optimize the space used. Warehousing is a big contributing cost to inventory carrying costs, so it would make sense to maximize the warehouse by optimizing the space. There are two main ways to do this.

Warehouse Layout can affect the productivity of a warehouse, as it influences the accessibility and utilization of the space. The layout of everything from the aisles to the racks, and to the forklifts is very important. Ways to improve accessibility would be by using the S-shaped or fishbone layout. The utilization could be optimized by using fixed slotting, or dynamic slotting. Lastly, productivity could be improved by implementing class-based storage, or by using the ABC analysis.

Warehouse Automation can reduce costs by reducing staff, error costs, and equipment costs. With the use of technology and software all operations and processes can be automated. Unfortunately, this technology comes with a hefty price tag for the initial investment, maintenance, and integration costs. After weighing up the costs and benefits, a company that wants to invest in software could use systems such as the automated storage and retrieval system (ASRS), or the robotic process automation (RPA).

In our modern age, technology has most often proven its use and ability in many facets of business management, and inventory carrying cost is no exception. Below are two examples of software applications that companies can employ to aid in their inventory management.

Inventory Management Systems makes it possible to manage and control everything from order quantity to safety stock, while simultaneously optimizing inventory decisions and reducing errors. Together, these reduce inventory carrying costs and improve visibility and accuracy. Some examples of inventory management systems are the enterprise resource planning system (ERP), and the material requirement planning system (MRP).

Warehouse Management Systems is a software that focuses on controlling every aspect of the warehouse itself. It manages everything from receiving, packing, and shipping, to optimizing the layout and improving efficiency. Excellent examples of warehouse management systems are the warehouse control system (WCS), and the warehouse execution system (WES).

Suppliers provide a business with everything they need including raw materials and finished goods. Negotiating the terms of the supply contract can reduce inventory carrying costs. A business could negotiate to lower the price, shorten the delivery time, or extend the payment period. Customers are any person or business that purchases your goods. Negotiating with customers could reduce your inventory carrying costs. Examples of this would be selling slightly damaged goods at a reduced price, as customers are often happy to buy something of a reduced quality if it costs them less money. A business could also ask a customer to pay over a shorter period of time by offering a slight discount in return.

Demand planning. Demand planning software helps insure you only hold the amount of stock needed to effectively meet customer demand. These systems use advanced AI and machine learning techniques to determine demand from sales history. Read more on these systems in our AI demand forecasting article.

Common Mistakes in Carrying Cost Management

Due to the complexity involved in inventory carrying cost management, there are several mistakes that can be made. These mistakes end up increasing your inventory carrying costs and reducing the overall performance of your inventory. One of the most common mistakes arises from obsolete methods and improper tool use. Examples of this include using paper records and doing manual calculations. Using these types of methods and tools can result in poor inventory decisions and high inventory carrying costs, simply because they are prone to unnecessary errors and inaccuracies. Thankfully, it is easy to avoid making this mistake by using modern methods and tools that can provide accurate and timely inventory data. Software applications and barcode scanners are two examples that can help you reduce your inventory carrying costs.

Our next example relates to incorrect demand forecasting. If a company uses forecasting techniques that rely solely on historical data or guesswork, they will have future demand results that are unrealistic and inaccurate. Having unreliable forecasts leads a company to make inventory decisions that result in stockouts or excess inventory, which increases inventory carrying costs. To prevent your company from suffering this fate, you need to ensure that appropriate demand forecasting techniques are being used. Statistical methods, market research, and customer feedback are all techniques that can help reduce inventory-carrying costs through reliable forecasts. Misunderstanding market trends is an additional mistake to look out for. Market trends and customer preferences are unpredictable, and any rapid changes that occur can result in obsolete inventory and high inventory carrying costs. Things that influence customer demand can range from the economic cycle to the weather. Therefore, it is vital that a company does not misunderstand how market trends impact demand and the value of their product. By conducting regular market analysis and customer surveys, a company can gain valuable insights to guide their inventory decisions and help them reduce their inventory carrying costs.

Furthermore, it is important to look out for errors involving inefficient inventory management and order fulfillment processes. If a company has low service levels, long lead times, poor quality control, and high order sizes, then there will undoubtedly be low inventory turnover and high inventory carrying costs. Customer dissatisfaction will also become a major concern. For this reason, a company must endeavor to improve its inventory management and order fulfillment process through creative problem-solving and the use of inventory management software. Once inventory turnover and performance have been corrected, inventory carrying costs will be lowered. But how exactly does inventory management software help to lower inventory carrying costs?

The Role of Inventory Management Software in Reducing Costs

Inventory management software is an incredibly beneficial tool that can be used to improve inventory performance, thereby reducing inventory carrying costs. To be specific, it provides three main advantages to inventory management. Firstly, it enhances data accuracy and visibility. It can collect, store, and analyze any inventory-related data. This includes the level of inventory, its current location, and its value. The software can also be linked to other locations and systems, such as the POS or ERP system. By compiling and sharing this inventory data, accuracy and visibility are increased, thus enabling a company to avoid errors that could result in over/understocking or misplacement of inventory.

Secondly, it can provide support that optimizes decision-making. The software has access to many models and methods, including ABC analysis, the FIFO method, and the EOQ model. It can employ them to calculate things like the optimal inventory level, safety stock, reorder point, and inventory value. A company can then use these results to make decisions that maximize inventory performance and profitability while reducing inventory carrying costs. Thirdly, the software can improve the efficiency of inventory management by automating various processes. For example, it could be used to automate the inventory ordering, receiving, and storing processes. Aside from automation, it can be used to boost efficiency by communicating with the inventory equipment (e.g., barcode scanners or RFID tags) to expedite inventory operations. When software is used to automate these processes it reduces error costs, the need for human labor, and the amount of space required by a business. Thus, software improves the productivity of the business and the inventory performance. Who would not be satisfied with all these benefits?!

Conclusions and Final Thoughts

It is of utmost importance to be able to identify where you might be incurring additional inventory carrying costs and how they might be coming about to nip this issue in the bud! There are various techniques to minimize inventory, and thus their carrying costs, to improve warehousing and inventory management systems, and manners in which inventory turnover time can be optimized, and therefore, sped up. Familiarise yourself with the common mistakes companies experience when creating higher inventory carrying costs for themselves, so you are able to identify these errors before they become a major issue.

Learn how AI driven demand planning software like Intuendi can help reduce inventory carrying costs.