Beginning with stating the obvious, it is absolutely essential for any business dealing with physical goods to conduct inventory audits. It is the most efficient way to combat fraud and theft, while also ensuring accurate inventory records and optimizing inventory management. In this article, we will discuss what an inventory audit is, its processes and methodologies, best practices and strategies, the utilization of technology in inventory audits, how to prepare the staff and documentation, and common challenges in inventory auditing.

What is Inventory Audits?

Dating back to ancient times, merchants used to keep track of their goods and transactions on papyrus scrolls and clay tablets. While much has changed since then, in our new world of technological innovations and modern accounting principles, some principles have kept to their roots and remained the same. Inventory auditing, or stocktake audit, at its core, is still the general process of comparing the physical count of the inventory with the accounting systems records, but also so much more. It includes checking that the condition of the inventory is good, classification of the inventory items, as well as their valuation.

Process and Methodologies

Inventory audits are complex and need to be flexible to suit different businesses, depending on the size, nature, and complexity of their inventory. They also require precision planning and execution.

Types of Inventory Audits

There are two main types of audits, internal audits and external audits. When a business conducts an internal audit it is done using their own accountants, inventory managers, and staff. The main purpose of an internal audit is to improve inventory control, monitor inventory performance, and comply with the internal policies and procedures of the business. External audits are usually conducted by independent third parties such as regulators or tax authorities. External audits provide assurance to investors by verifying financial statements, and ensuring that the business complies with external standards and regulations.

A third type of inventory audit is one that is classified by the frequency in which they occur, namely continuous audits or periodic audits. Continuous audit means it is done randomly and regularly throughout the year, to keep track of inventory movements and transactions. This is a more proactive method and it can help you identify any small problems before they become a big issue. Periodic audits are less frequent and are usually only done once a year, most often at the end of the fiscal year. This gives the business a more overall picture of their results and inventory performance and is more retrospective and corrective.

Key Audit Procedures

Various audit procedures must be used to determine if one’s inventory records are accurate and reliable.

ABC Analysis

ABC Analysis is a method that is used when prioritizing inventory items and deciding how to distribute auditing resources efficiently. It works by assigning the most valuable and frequently used items to group “A”, moderate items to “B”, and the least valuable/frequently used to “C”. The group “A” inventory is prioritized and gets the most detailed and frequent audits, while group “C” has simplified and infrequent audits.

Analytical Procedures

Analytical Procedures, which compare the inventory data with other relevant data (e.g., industry averages and historical trends). This helps identify any unusual variations in the data, which could indicate possible fraud or errors. An example of this procedure would be an auditor comparing the inventory turnover rate with the previous year’s rate to assess liquidity.

Cut-off Analysis

The next procedure is Cut-off Analysis. This method is used to avoid potentially over or understating the inventory balance and its related expenses. It does this by ensuring that all inventory transactions are recorded within the correct accounting period. One can apply this procedure by having an auditor examine shipping documents, such as invoices, to check that goods shipped toward the end of the period are accounted for correctly.

Finished Goods Cost Analysis

Finished Goods Cost Analysis is another important procedure. It verifies that the cost of goods that are ready for sale is valued at the lower of cost or market value, in accordance with the accounting principle for inventory valuation In this procedure an auditor will review the cost of goods sold during the period to determine if the finished goods inventory value is reasonable.

Freight Cost Analysis

When a business has to pay to transport goods from the supplier to them, and then to the customer; Freight Cost Analysis becomes a useful procedure. It helps to ensure that the freight costs are correctly allocated and recorded, according to the purchase agreement. To do this, an auditor will inspect freight invoices and contracts to ensure freight costs are paid and reflected in the inventory valuation.

Matching and Reconciliation

The final procedure that comes into play is Matching and Reconciliation. This procedure compares physical inventory counts with accounting system records to identify discrepancies. This allows for any errors and adjustments to be properly explained and documented. An example of this would be an auditor reviewing count sheets and reconciling their findings with the inventory ledger in order to provide evidence indicating that the ending inventory balance is correct.

Best Practices and Strategies

Inventory audits aren’t necessarily the simplest of tasks, but there are certainly ways to be more efficient. What are the best auditing procedures for inventory? Let’s go through some strategies to help make your audits as effective as possible. Here are a few audit procedures for inventory:

Planning the Audit: Timing and Organization

Planning is crucial to make your audit as organized as possible. This means balancing your objectives with your resources and timing. One of the key aspects is Timing. Audit timing depends on various factors such as the frequency of the audit and the availability of staff and inventory. When inventory level is low and business is slow, it is generally considered to be a good time to conduct a periodic inventory audit. This enables you to have a more accurate audit while reducing the disruption in the daily running of the business. On the other hand, a continuous audit is best done more randomly. The surprise aspect means that there is less chance of someone tampering or manipulating inventory records. Organization is also crucial when planning an inventory audit. A business needs to have a solid audit plan, with tasks being assigned and communicated well to the relevant parties. A well-coordinated team ensures a smooth audit process. A team may consist of a lead auditor who supervises, and assistants who perform procedures and tests. The plan could outline the timeline and what methods are used. The audit expectations could include rules and standards.

Inventory Counting Methodologies

The main activity of any audit is physical inventory counting. This way, a business can confirm the existence and condition of the inventory, providing a base for inventory valuation and reconciliation. The two main methods of inventory counting are cycle counts and physical counts.

Cycle Counts

Cycle counts do not focus on the entire inventory, but rather on specific categories that can be counted at regular or random intervals. This method is best suited for a business operating in a dynamic environment with a diverse, complex inventory. The cycle count method helps to monitor inventory movement more closely, enabling them to identify any errors timeously, and ensuring a more reliable inventory record.

Physical Counts

Physical counts involve counting the entire inventory at the end of an accounting period or year. The detailed count verifies the ending inventory balance and the related expenses and revenues and must comply with external standards. Physical counts are best suited for businesses operating in a regulated environment and have small, stable inventories.

Cycle Counts vs. Physical Counts

When used together these two counting methods can achieve optimal inventory audit results. Using the ABC method discussed earlier in this article, a business can use cycle counts to monitor its inventory throughout the year. The physical count can be done at the end of the financial year to verify and reconcile the inventory.

Utilizing Technology in Inventory Audit

Technology helps streamline the auditing process while improving its accuracy and efficiency. There are different types of technology tools one can use to enhance the inventory auditing process. Barcode Scanners speed up inventory counting by reading and capturing barcodes attached to inventory items. They record inventory data in seconds, eliminating the need for manual entry and reducing human errors or bias during the counting process. RFID tags are another useful tool. They are tiny electronic chips that store and transmit inventory data using radio waves. RFID enables a business to monitor inventory movements and transactions in real-time, improving the visibility and traceability of the inventory, without any physical contact. This up-to-date information on the inventory status and location improves the accuracy of the inventory data. The third technology tool is Inventory Management Software. These are applications that store and process inventory data. They can integrate data from various sources such as point-of-sale systems, and warehouse systems, which helps optimize inventory management. This software can also analyze and evaluate inventory performance. Lastly, we have Cloud Computing. This stores all the inventory data and makes it possible for the audit team to access and share this data from anywhere and at any time. Cloud computing backs up data to remote servers and keeps it secure from any unauthorized access.

Documentation and Staff Preparation

These two important aspects of the inventory auditing process help ensure audits are conducted ethically and that results are valid and reliable. Documentation is a process where the audit procedure and findings are recorded, providing evidence of the audit results, which is then communicated to all relevant parties. It helps with the evaluation of the audit quality and accountability. One key element of documentation is the Audit Plan and Schedule. These documents guide the audit process by outlining its scope, timeline, methodologies, objectives, and procedures. This ensures its goals are achieved within budget and on time. Another key element is Audit Working Papers, which are documents that record the audit data and calculations. These document the audit procedures, and provide the basis for the audit findings. The third key element of documentation is the Audit Report. This document provides a summary of the audit results and recommendations and communicates them to management and stakeholders. It also provides suggestions for inventory improvements.

Staff preparations ensure staff are competent and qualified for the audit, by providing training and education on the audit process. Audit training gives the staff a good understanding of the audit standards and rules while providing them with the necessary skills and techniques. It ensures an audit team that is capable and confident and can carry out the audit correctly and consistently. Inventory education provides staff with instructions on the audit purpose and methodology. This helps the staff assist the audit team competently and creates a cooperative environment.

Common Challenges in Inventory Auditing

It is important to maintain awareness of the challenges that have the potential to hinder the inventory audit process. However, we have compiled a list of some of the most common ones to look out for, hopefully aiding in your ability to spot, avoid, and mitigate them.

Time-consuming Nature

Counting a large number of inventory items can be time-consuming, not to mention the time spent recording and reporting the audit results. Depending on the scope of the audit, and the complexity of the inventory, an audit could take anywhere from a few hours to a few weeks. This could be extremely disruptive to the daily operations of a business, which could affect productivity and profitability.

Difficulty in Scaling

There are so many factors that make an inventory audit difficult to scale. In a growing business, and a business that operates from several locations, markets, and channels, inventory auditing can present more and more challenges. Difficulty in scaling inventory auditing can cause inaccuracy and inefficiency in inventory management, which will affect the sustainability of the business.

Operational Interruptions

Inventory auditing interrupts the normal flow of the inventory, and can affect availability and accessibility, as inventory may be moved or locked during the audit. Delays in inventory transactions can cause some inaccuracies in inventory records. These interruptions could lead to dissatisfied customers and frustrated staff.

Tips for Efficient Auditing

And now that we’ve identified some common challenges, let us explore some tips to make the task of inventory auditing more manageable, hopefully aiding in risk aversion!

Identify and Prioritize Inventory Items

The previously discussed ABC method is highly effective when it comes to identifying and prioritizing inventory items. Knowing where best to focus your precious audit resources and efforts will make the audit process more efficient.

Scheduling Recurring Audits

Scheduling regular or random recurring audits throughout the year is a worthwhile method. This gives you much better control of inventory movements and transactions, making it possible to detect and correct errors quickly before they get too bad. The inventory records will be more accurate and reliable, and it will help avoid unexpected discrepancies. It lessens the workload and the disruptions while allowing the audit team to perform a more focused audit.

Conducting Bias-free Audits

Bias-free audits are impartial and objective and remain free from any influence or interference from staff or management. This ensures a valid and reliable audit result. A bias-free audit of inventory can be achieved by using independent and qualified inventory auditors, who have no affiliation to the business or inventory. With their knowledge and skills, they can apply standards consistently, while providing a neutral and professional perspective. Another way to achieve a bias-free audit is by using random and surprise audits. These audits are random and unannounced and therefore prevent any preparation or altering of inventory records. The third way of conducting a bias-free audit is through the use of blind counts. This is based purely on a physical observation and does not rely on inventory records at all. This way the inventory count is accurate without any possible errors or bias from inventory records.

Importance of Audits in E-commerce and Beyond

In the ever-changing world of business, inventory audits are the one thing that has remained crucial, in both traditional businesses and e-commerce and beyond. E-commerce is any internet-based business that sells products or services online. Rapid advancements in technology and the convenience of online shopping have resulted in substantial growth in e-commerce. The inventory of an e-commerce business is larger, offering a wide variety of products to a more diverse customer base. This poses several challenges for inventory management and auditing. Inventory audits help ensure that the products are in good condition and are readily available for speedy delivery to customers. It also reduces the risk of theft, fraud, or errors, thereby protecting the reputation of e-commerce and ensuring customer satisfaction.

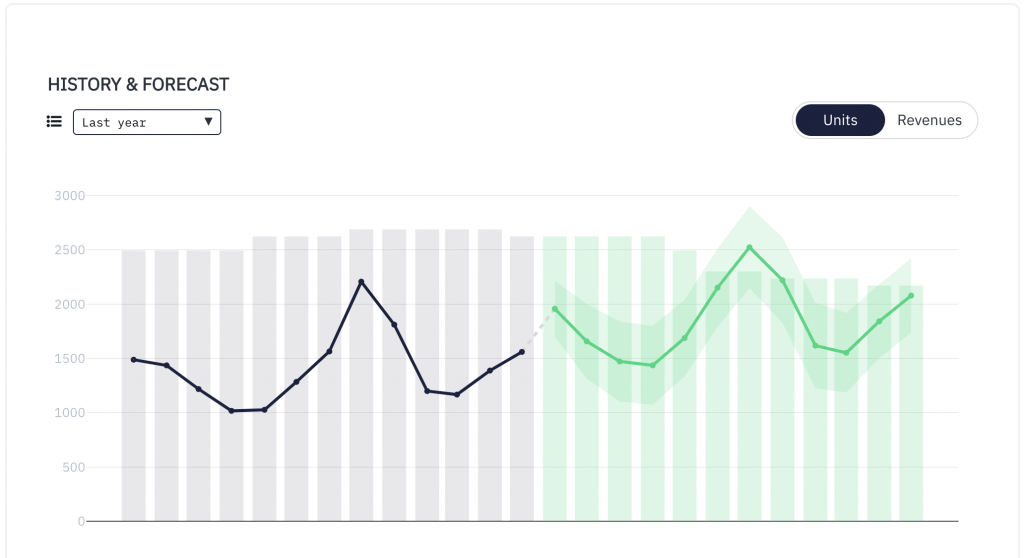

Inventory audits help improve the performance and profitability of e-commerce and beyond. They provide important insight into the inventory data, such as inventory turnover and variance, which helps optimize inventory management. They also identify areas where control measures can be improved, resulting in inventory reduction and optimization. This all increases sales, reduces expenses, and creates better cash flow. Another important function of inventory audits in e-commerce is that they help evaluate and measure inventory performance by using performance indicators and benchmarks. Benchmarks such as historical trends and industry averages are the standards used to compare inventory performances. Performance indicators are the metrics used to quantify inventory performance, such as inventory efficiency, and inventory accuracy. Together they provide a comprehensive picture of the inventory performance.

Conclusion

Inventory audits ensure accurate records, optimize inventory management, improve financial performance, and prevent theft. There are different audit methodologies, including key procedures, best practices, tips for efficient auditing, and common challenges. Inventory audits, furthermore, hold immense importance in e-commerce to ensure the availability of products, customer satisfaction, and profitability. While inventory audits are not easy, the use of tools and technology can make it far more efficient, and best practices make the audit more effective. Inventory audits provide assurance for stakeholders and the public while creating value and impact.

Learn more on how Intuendi AI can help with your inventory management: