Ever wondered how businesses strike the perfect balance—never overstocked, never out of stock? The answer lies in average inventory, a crucial metric that helps companies maintain just the right amount of stock. By calculating average inventory, businesses can optimise cash flow, improve storage efficiency, and ensure they always have enough to meet customer demand. It’s the secret ingredient to smarter inventory management!

What is Average Inventory?

Think of average inventory as the pulse of your stock levels—a rolling snapshot that smooths out fluctuations over time. Instead of relying on a single moment’s data, it calculates the mean inventory value over a period (month, quarter, or year). This ensures businesses don’t fall into the trap of overstocking or running out of essentials, striking a balance between availability and efficiency. Whether it’s keeping retail shelves stocked during peak seasons or avoiding excess storage costs, mean inventory is a vital tool for smarter inventory decisions.

Why Does It Matter?

Mean inventory isn’t just a number—it’s a business game-changer. It helps control costs by preventing excessive storage expenses while avoiding stockouts that frustrate customers. It optimises supply chain planning, ensuring businesses can predict demand shifts and adjust orders accordingly. Most importantly, it enhances cash flow by freeing up capital that would otherwise be tied up in excess stock—allowing businesses to invest in growth, innovation, and customer experience. When used effectively, mean inventory helps businesses stay agile, profitable, and ready for whatever the market brings.

Mastering Average Inventory: How to Calculate It Like a Pro

The Simple Formula

At its core, calculating average inventory is straightforward:

This formula provides a midpoint value, offering businesses a clearer picture of their typical inventory levels over time. By tracking this metric, companies can fine-tune their purchasing and stocking decisions, reducing costs and improving efficiency.

Different Methods for Different Needs

Not all businesses operate the same way, so inventory calculations need to adapt:

- Simple Average – Best for companies with stable stock levels.

- Moving Average – Ideal for businesses facing gradual inventory changes, smoothing fluctuations.

- Weighted Average – Used when products vary in cost or importance, prioritising key stock items.

Putting It into Practice

Imagine a retail store starts the month with $10,000 in inventory and ends with $14,000.

This means the store typically held $12,000 worth of inventory throughout the month, guiding smarter restocking and budgeting.

Scaling Up: Quarterly Calculation

For businesses tracking trends over longer periods, the same logic applies. A retailer calculating quarterly inventory could:

- Use Monthly Averages – Add monthly averages and divide by the number of months.

- Total Beginning & Ending Inventory – Sum the values across months and divide accordingly.

For example, if the monthly averages for January, February, and March are $12,000, $15,000, and $17,000, then:

This approach is invaluable for seasonal businesses, like toy stores preparing for holiday spikes, ensuring enough stock is available without excess inventory weighing down cash flow.

Tracking mean inventory isn’t just about numbers—it’s about strategic decision-making that keeps businesses agile, efficient, and profitable.

Choose the right method for your business.

Setting the Right Inventory Baseline: Beginning & Ending Inventory

Getting average inventory right starts with accurate beginning and ending inventory values—the foundation of smart stock management. Any miscalculations here can distort insights, leading to costly mistakes.

Choosing the Right Inventory System: Periodic vs. Perpetual

When it comes to tracking stock, businesses have two main options: Periodic Inventory and Perpetual Inventory. Each method suits different business needs, depending on scale, accuracy requirements, and available technology.

Periodic Inventory: Simple but Limited

The Periodic Inventory System updates stock levels at set intervals (monthly, quarterly, or annually) through manual counts. It’s a cost-effective, straightforward approach, often used by small businesses.

Pros:

- Easy to implement and understand

- Low-cost, requiring minimal technology

Cons:

- Time-consuming manual counts

- Prone to human error

- No real-time inventory updates

Best for: Small businesses or companies with a limited product range that don’t need real-time tracking, such as local boutiques conducting monthly stock counts.

Perpetual Inventory: Real-Time Precision

The Perpetual Inventory System provides continuous stock tracking using software, barcode scanners, and RFID technology. Every transaction updates inventory instantly, offering businesses real-time visibility.

Pros:

- Highly accurate with automated tracking

- Reduces manual workload

- Prevents stockouts and overstocking

- Enables better decision-making with real-time data

Cons:

- Higher upfront cost for technology and setup

- More complex to implement and maintain

Best for: Businesses requiring real-time accuracy, such as large retailers, e-commerce platforms, and manufacturers. For example, an online store can automatically update product availability with every sale, reducing overselling risks.

Bottom line: If simplicity and affordability matter, Periodic Inventory works. If precision and efficiency are key, Perpetual Inventory is the way forward.

What Influences Average Inventory?

Mean inventory is shaped by various internal and external forces. Businesses must consider demand fluctuations, lead times, seasonality, and economic conditions to maintain optimal stock levels. Understanding these factors helps companies fine-tune inventory strategies, ensuring they have the right products at the right time without overstocking or running out.

The Forces Shaping Average Inventory

Inventory levels don’t exist in a vacuum—they shift in response to customer demand, supplier reliability, seasonal trends, and economic conditions. Businesses that anticipate these changes can optimise stock levels, avoiding costly shortages or excess inventory.

-

Demand Fluctuations: The Customer Pulse

Trends, marketing campaigns, and external events can cause spikes or drops in demand. A fashion brand might see a surge in sales after a celebrity endorsement, while a tech retailer may struggle with slow demand post-holiday season. Using historical sales data, market research, and predictive analytics helps businesses stay ahead of demand swings.

-

Lead Times: The Waiting Game

Longer supplier lead times require businesses to keep extra stock to avoid stockouts. A restaurant waiting four weeks for ingredient deliveries must have enough supply to bridge the gap. Strategies like negotiating faster deliveries, sourcing multiple suppliers, and improving order processing help reduce lead-time risks.

-

Seasonality: Timing is Everything

Seasonal shifts heavily impact industries like fashion, tourism, and agriculture. Retailers stock up on winter coats in autumn and summer essentials in spring. Businesses can plan ahead for peak seasons, clear out off-season stock through promotions, and use past data to refine forecasts for better inventory control.

-

Economic Conditions: The Big Picture

Inflation, recessions, and supply chain disruptions reshape inventory decisions. During economic downturns, consumer spending dips, while inflation increases holding costs. Businesses can diversify suppliers, use economic forecasts to adjust stock levels, and implement flexible inventory strategies to stay resilient.

The best inventory strategies are proactive. Understanding these factors allows businesses to predict, adapt, and thrive, no matter what the market throws their way.

How Businesses Use Average Inventory

Mean inventory is a powerful tool that helps businesses optimise stock levels, improve demand forecasting, and assess operational efficiency. By leveraging this metric, companies can make smarter decisions, ensuring they have the right inventory at the right time while keeping costs under control.

Striking the Perfect Inventory Balance

Mean inventory helps businesses avoid two costly mistakes—overstocking and stockouts. By analysing inventory trends, companies can adjust stock levels, ensuring they meet customer demand without tying up excess capital in unsold goods. A retailer, for example, can use average inventory data to reduce overstocked items and reinvest in better-performing products.

Smarter Demand Forecasting

Past inventory trends reveal valuable insights into seasonal demand patterns. A toy store noticing a surge in average inventory before the holidays can adjust future orders to prevent stock shortages while avoiding unnecessary overstocking. Predicting demand more accurately leads to better purchasing decisions and improved cash flow.

Measuring Business Efficiency

Mean inventory plays a key role in inventory turnover analysis, helping businesses assess how efficiently they manage stock. Comparing turnover rates with average inventory levels can reveal potential issues:

| Inventory Turnover | Average Inventory | Business Insight |

| High | Low | Strong sales, efficient inventory management |

| High | High | Strong sales but potential risk of stockouts |

| Low | Low | Weak sales, possible obsolescence risk |

| Low | High | Overstocking, high carrying costs, poor demand forecasting |

Tracking average inventory alongside turnover rates helps businesses identify inefficiencies, reduce excess stock, and optimise inventory planning for greater profitability and smoother operations.

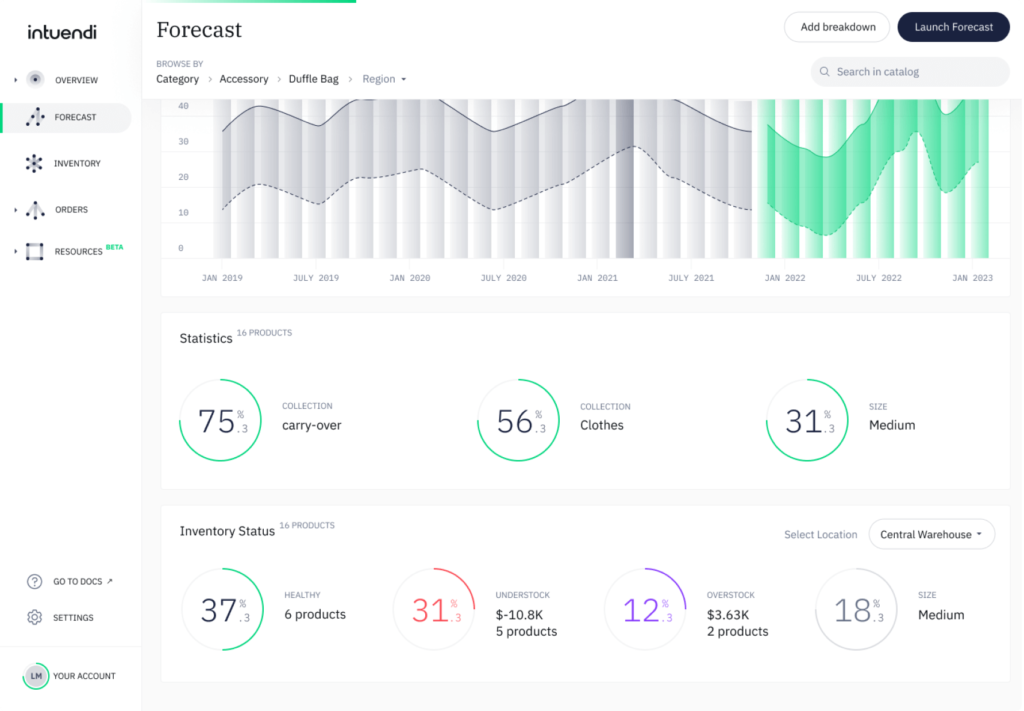

Tech Solutions for Smarter Inventory Management

Managing mean inventory efficiently requires more than guesswork—modern tools and technologies provide real-time tracking, automation, and data-driven insights. These solutions enhance accuracy and streamline operations.

Smart Tech for Smarter Inventory Management

Modern businesses don’t leave inventory management to chance—technology does the heavy lifting. The right tools help companies optimise stock levels, reduce errors, and make data-driven decisions.

Inventory Management Software: The Digital Command Center

- Real-time tracking of stock, sales, and deliveries

- Automation for reordering and stock counting

- Seamless integration with sales, accounting, and e-commerce platforms

- Analytics & insights for better decision-making

Barcoding & RFID: Precision Tracking Made Easy

- Barcoding: Scans product movement quickly and cost-effectively

- RFID: Uses radio waves for faster, bulk inventory tracking—no scanning required

Data Analytics & Forecasting: Predicting What’s Next

- Trend analysis to spot seasonal demand shifts

- Predictive analytics for smarter stock planning

- Inventory optimisation to cut costs and boost efficiency

The takeaway? With the right tech, businesses can manage inventory faster, smarter, and with fewer costly mistakes.

The Hidden Gaps in Average Inventory: Challenges & Fixes

While mean inventory is a valuable tool, it’s not perfect. It smooths out data over time, which can hide short-term stock fluctuations and distort turnover insights—potentially misleading businesses about their actual inventory health.

The Key Challenges:

- Short-Term Fluctuations Disappear – A retailer may sell out of a trending product due to a flash sale, but the average inventory won’t reflect that temporary stockout.

- Irregular Turnover Skews the Data – Slow-moving products can inflate average inventory figures, making it seem like there’s more stock than there actually is.

How To Work Around These Gaps:

- Use More Granular Data – Instead of relying on monthly or quarterly averages, track weekly or daily inventory trends for a more precise view.

- Segment Inventory – Break inventory down by product category or turnover rate to spot discrepancies between fast- and slow-moving stock.

- Combine Metrics – Pair average inventory with inventory turnover, sell-through rate, and stock-to-sales ratio for a full picture.

- Leverage Real-Time Tracking – A perpetual inventory system keeps businesses updated on stock levels instantly, helping them react faster to changes.

Bottom Line?

Mean inventory is a great starting point, but real-time insights and complementary metrics make it a powerful decision-making tool.

Mastering Average Inventory: Best Practices for Smarter Stock Management

Optimising average revolves around having the right stock at the right time. Businesses that fine-tune their inventory strategies can improve cash flow, reduce waste, and boost efficiency. Here’s how:

Demand Forecasting: Predicting What’s Next

Accurate demand forecasting prevents overstocking and stockouts. Businesses can analyse past sales, conduct market research, and use predictive analytics to anticipate future demand.

Inventory Turnover Ratio: The Speed Test

A high inventory turnover ratio signals efficient stock movement, while a low ratio can indicate overstocking or weak demand. Businesses can adjust pricing, enhance marketing, and streamline product lines to optimise turnover.

ABC Analysis: Prioritising the Essentials

Not all stock is equal—ABC analysis categorises inventory into:

- A-items: High-value, critical stock needing tight control

- B-items: Moderate-value, important but less critical

- C-items: Low-value, high-volume items requiring minimal oversight

Safety Stock: The Backup Plan

Holding extra inventory mitigates risks from demand fluctuations and supply delays. Factors like demand variability, supplier lead times, and service levels determine safety stock levels.

Integration is the future of your business.

Finding the Right Balance: High vs. Low Average Inventory

Businesses must strike the right balance when managing mean inventory levels—too much can tie up capital, while too little can lead to stockouts. Here’s a closer look at the pros and cons of each approach.

High Average Inventory: Stocking Up for Security

Pros:

- Fewer stockouts → Happier customers & consistent sales

- Bulk buying savings → Lower per-unit costs

- Supply chain buffer → Protection against delays & shortages

Cons:

- Higher carrying costs (storage, insurance, handling)

- Risk of obsolescence (especially for seasonal or tech products)

- Tied-up capital (less cash available for growth investments)

Low Average Inventory: Lean & Agile

Pros:

- Lower storage & insurance costs

- Reduced risk of obsolete stock

- More liquidity for business growth

Cons:

- Stockouts risk → Lost sales & unhappy customers

- Supply chain vulnerabilities → Less room for delays

- Higher per-unit costs → No bulk discounts

The Bottom Line?

Neither high nor low mean inventory is perfect—the best approach depends on industry, demand patterns, and cash flow needs. Smart businesses balance stock levels strategically, using forecasting, automation, and supplier coordination to stay stocked without overspending.

The Art of Balancing Inventory: Stock Smart, Sell Smarter

Finding the sweet spot between too much and too little inventory is key to keeping costs low while meeting customer demand. The right balance depends on industry dynamics, market trends, and business strategy.

What Influences Inventory Balance?

- Demand Variability – High fluctuations? Keep safety stock ready.

- Supplier Lead Times – Longer wait times? Hold extra stock.

- Product Type – Perishables and trend-sensitive items? Keep inventory lean.

- Market Trends – Stay ahead of shifting demand.

- Financial Position – Strong cash flow? More inventory flexibility.

- Smart Strategies for Perfect Inventory Balance

- Real-Time Monitoring – Adjust stock levels based on live data.

- Advanced Forecasting – Use AI-driven demand predictions.

- Supplier Collaboration – Improve lead times & reliability.

- Flexible Policies – Adapt quickly to changing demand

The Takeaway?

Balancing inventory isn’t guesswork—it’s a strategy. Businesses that fine-tune stock levels using data, technology, and supplier coordination can boost profitability while staying agile.

Real-World Wins: How Top Brands Master Inventory Management

Great inventory management boils down to strategy. Here’s how three industry giants fine-tune their average inventory levels to drive efficiency, reduce costs, and stay ahead of the competition.

Amazon: Data-Driven Inventory Powerhouse

- The e-commerce giant optimises inventory with technology, automation, and predictive analytics.

- AI-Driven Forecasting – Predicts demand to adjust stock across fulfillment centers.

- Automation & Robotics – Speeds up inventory handling and reduces errors.

- Dynamic Pricing – Adjusts prices in real time to influence demand.

Result: Always-stocked shelves, fast delivery, and cost efficiency—a key factor in Amazon’s market dominance.

Zara: Fast Fashion, Faster Inventory Turnover

- Zara’s inventory strategy is built for speed and adaptability in the ever-changing fashion industry.

- Just-in-Time (JIT) Restocking – New stock arrives multiple times per week.

- Vertical Integration – Owns much of its supply chain, enabling rapid adjustments.

- Real-Time Sales Data – Monitors trends to tweak inventory instantly.

Result: Lower inventory, less waste, and ultra-fast trend response, making Zara a global leader in fast fashion.

Toyota: Lean, Mean, Manufacturing Machine

- Toyota’s Just-in-Time (JIT) model revolutionised lean inventory management.

- Kanban System – Uses visual cues to signal real-time part needs.

- Close Supplier Collaboration – Ensures on-time delivery of critical components.

- Continuous Improvement – Constantly optimises processes to reduce waste.

Result: Minimal holding costs, streamlined production, and world-class efficiency, securing Toyota’s reputation for quality.

Key Takeaway?

Different industries, different strategies—but the best businesses use data, automation, and supply chain agility to strike the perfect inventory balance. Want to stay ahead? Learn from the best.

The Future of Average Inventory Management: Smarter, Faster, and Greener

Inventory management is evolving rapidly, driven by cutting-edge technology and shifting business priorities. The future will be shaped by artificial intelligence, real-time tracking, blockchain transparency, and sustainable practices, helping businesses streamline operations while reducing waste.

Artificial Intelligence and Machine Learning

AI and ML are transforming inventory management by making demand forecasting more precise, optimising stock levels, and automating decision-making. These technologies analyse vast datasets to predict trends, ensuring businesses maintain the right stock at the right time.

Key impacts:

- More accurate demand forecasting, reducing stockouts and overstocking

- Automated stock adjustments based on real-time data

- AI-powered insights for smarter inventory decisions

The Internet of Things (IoT) and Real-Time Tracking

IoT technology connects inventory to the digital world, providing real-time tracking, condition monitoring, and automated alerts. Sensors can monitor stock levels, track shipments, and ensure product quality.

Key impacts:

- Live updates on stock location and availability

- Automated alerts for low inventory or product expiration

- Condition monitoring to prevent spoilage in industries like food and pharmaceuticals

Blockchain for Transparency and Security

Blockchain technology is enhancing inventory traceability, reducing fraud, and improving collaboration across supply chains. By creating an immutable record of transactions, businesses can track inventory from origin to final sale.

Key impacts:

- Increased traceability of stock movement

- Protection against fraud and counterfeit goods

- Strengthened trust between supply chain partners

Sustainability and the Circular Economy

As businesses move toward greener operations, inventory management is shifting to reduce waste and support a circular economy. Companies are exploring ways to reuse, recycle, and minimise excess stock.

Key impacts:

- Lower waste through sustainable stock management

- More efficient resource use by preventing overproduction

- Adoption of circular inventory models that promote recycling and reuse

What’s Next?

With AI-driven forecasting, IoT-powered tracking, blockchain security, and sustainability initiatives, inventory management is becoming faster, smarter, and more responsible. Businesses that embrace these innovations will gain greater efficiency, stronger supply chains, and a competitive edge in a rapidly changing world.

The Path to Smarter Business Decisions

Average inventory is a strategic tool that helps businesses balance supply and demand, reduce costs, and improve efficiency. From calculating it accurately to leveraging best practices, businesses that refine their inventory management can boost profitability and streamline operations.

By applying forecasting techniques, real-time tracking, and smart inventory strategies, companies can maintain just the right amount of stock—enough to meet customer needs without unnecessary storage costs. Whether it’s using AI-driven insights, IoT tracking, or sustainable practices, the future of inventory management is about precision, agility, and innovation.

The journey to optimising inventory never truly ends, but with the right tools, data, and strategy, businesses can stay ahead, adapt to market changes, and drive long-term success.

Let Intuendi orient your data to do the heavy lifting.