It is difficult to manage, in a suitable and efficient way, a complex supply chain. Optimization comes as a very useful tool in trying to cut down costs, while scheduling operations in such a way that deadlines are met, resources are not exhausted, and cost is optimized.

However, there might be additional difficulties right behind the corner. One of the best-known is the so-called “Bullwhip effect”. In this article, I will explain what it is and why it might arise.

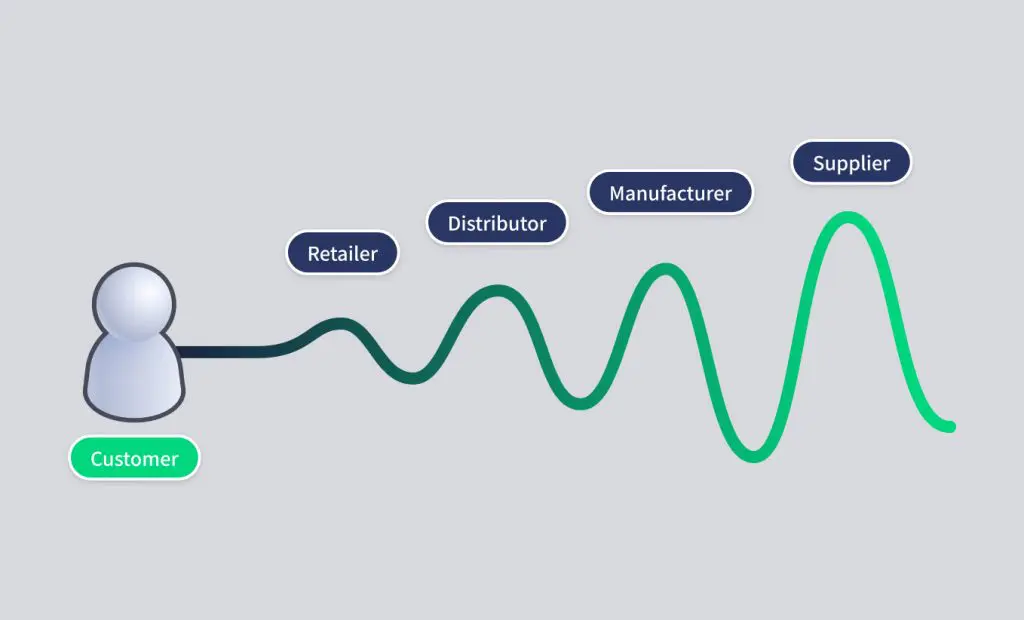

Suppose you have a relatively simple logistic chain composed, for example, of a retailer, a distribution center, a wholesaler, and a production unit.

What causes the Bullwhip Effect?

Two of the basic ingredients which cause the bullwhip effect might be present, and indeed quite frequently are present, in supply chains:

- Lack of communication between stages in the chain

- Long lead times and/or setup times

The first ingredient arises when the chain is composed of somewhat separated stages, with little or no information sharing. In this case, as an example, the retailer is the unique part of the whole chain that can “see” the actual demand. Thus the retailer can observe sudden changes in demand, regular patterns, seasonality, etc. The retailer might even be able to make good demand forecasts. This is gold for any company. But many companies do not use this gold mine suitably. Let’s assume that the retailer does not share the available information with others in the chain, notably with the direct upstream stage, the distribution center. The only information the retailer sends to the distribution center is a list of purchase orders. The distribution center, now, considers the retailer as the unique, internal, customer and tries to cope with current and, possibly, future demand. Notice: in this case, it is the internal demand generated by looking at purchase orders, not the real, external, demand of real customers. The wholesaler, upstream of the distribution center, will behave in a similar way as well as the production unit. Eventually, considering the communication delays which are inevitably present in this situation, the production unit will receive a production order which is somewhat related to the real demand but has been filtered by several intermediate stages that do not communicate well with each other. Production will take some time, but eventually will be shipped to the wholesaler; after some time the wholesaler will fulfill internal orders from the distributor, who in turn will pass, with some delay, finished products to the retailer. Eventually, some part of the demand will get satisfied.

All ok? Not really…

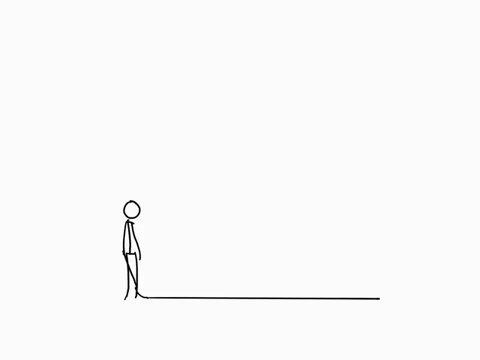

This management strategy has a very high risk of generating the bullwhip effect. This phenomenon gets its name from the well-known rope used in many movies or cartoons:

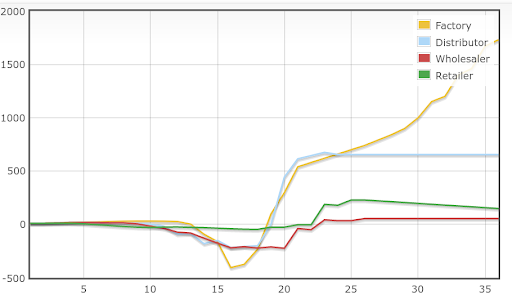

As you can see in the image above, the rope oscillates and the amplitude of the oscillations increases as the distance from the customer increases.

The Bullwhip Effect in supply chains

What happens in supply chains is that a possible, very small, fluctuation in real demand (a small increase or decrease) produces a set of amplified responses from the upstream stages. That is, the retailer will place a slightly larger-than-usual size order; the distributor, seeing an increase in internal demand, will require more from the wholesaler who in turn will ask for more from the factory. Here time comes into play: in fact, from the moment at which the demand increased to the moment production starts, a time interval will be passed. During this interval, the retailer, seeing that no additional products get delivered will likely issue a further order for replenishment, even if the demand returns to the usual standard. This will generate a reaction on the upstream stages who will, in turn, order more. By the time the first additional product reaches the retailer, there will be, on one side, unsatisfied customers, and on the other side, many additional orders will have been issued and, sooner or later, inventories will grow. Once inventories, at all stages, grow, the reaction will be to order less and less.

And so it is easy to see the parallel with the bullwhip: inventories (or backorders, in case they become negative) oscillate at any stage because of delayed over-reaction to the current situation. Moreover, the farthest a stage is from the real customers, the larger the oscillation will be, with a maximum variability usually seen in the production unit. Here quite frequently huge production orders are followed by long periods with no production at all.

The beer game

This phenomenon has been studied very deeply in best practices and management literature – one of the pioneers in this field was a professor at M.I.T., Jay Forrester, who studied supply chains from a dynamical system point of view. What is now known as the bullwhip effect was known, for a long time, as the Forrester effect. Jay Forrester also invented a simulation game, the Beer game, designed to show, in a simple and practical way, the concrete possibility that the bullwhip effect manifests itself in a real-life situation.

In this game, originally played with a set of special cards, but nowadays available in many software implementations, each player is the manager of a single stage in the chain and has just to decide, from day to day, how much to order from the direct upstream stage or, in case of the factory, how much to produce. In its standard setting, the external demand, which is seen only by the retailer, is almost always constant, apart from a tiny jump in the beginning of the simulation. It almost invariably happens that the bullwhip effect becomes extremely relevant very soon. Below we report the inventory levels during an actual run of the simulation game:

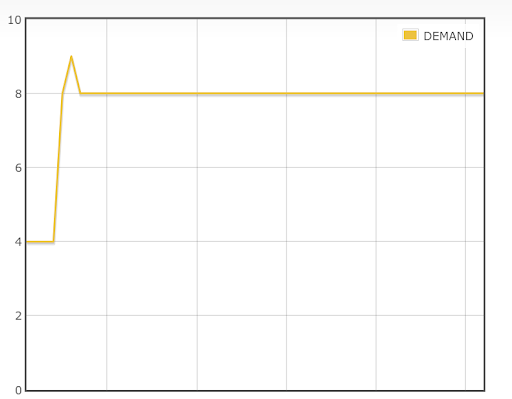

We can clearly see the shape of the bullwhip and also the order of magnitude of inventory levels (negative inventories correspond to backorders). This exaggerated reaction was not due to unusual or unpredictable demand patterns. In fact, in this example, the demand was this one:

This means that real customers asked for 4 units first, then 9 units just once, and then the demand remained stable to 8 units, forever!

The above behavior is not (only) due to some ingenuity of the players. It is mainly due to the lack of communication between stages, the delays (of information on orders upstream and delivery downstream), and to the fact that every stage is quite isolated and tries to optimize its internal KPI’s without taking into consideration the effects of decisions taken by other stages of the supply chain.

How to avoid the Bullwhip effect in your supply chain

There are of course remedies to avoid the bullwhip effect. One is information sharing and transparency: if all stages have access to all the information (on real demand, internal demand, on-hand inventories, shipped units, future orders,…).

Another one is trying to keep delays, setup times, and shipment times, at their minimum, in order to be able to react in a suitable way to changes in external demand.

Another remedy is also to rely on a global optimization tool capable of optimizing decisions across the entire supply chain, as opposed to the myopic strategy of trying to optimize each stage separately.

It would also be very helpful to use an accurate demand forecasting software, to be able to distinguish a transient demand pattern from a regular one.

Intuendi was born just to solve these problems in the most efficient way possible…