All it takes is an empty shelf to lose a customer forever, and a delayed shipment to halt an entire production line. In business, things like this are not just minor hiccups, they are detrimental. These mistakes are fractures in the very foundation of how value is created and delivered. The architecture that prevents these fractures is a company’s supply chain model, a strategic framework governing the entire flow of goods, information, and finances from raw material to final consumer. Understanding this architecture isn’t just a task for logistics managers. It is a fundamental requirement for anyone aiming to build a resilient, efficient, and competitive enterprise in a world where speed and reliability are currency.

What Is a Supply Chain Model?

A supply chain model is the operational blueprint that dictates how a company manages its supply chain. It’s not the same as a strategy, which is the “why,” or supply chain management (SCM), which is the day-to-day “how.” The model is the “what”—the specific structure designed to achieve a company’s goals.

At its core, every model navigates a fundamental trade-off between responsiveness and efficiency. Should the chain be built for lightning-fast reactions to unpredictable demand, or should it be optimized for the lowest possible cost per unit in a stable market? There is no single correct answer. A one-size-fits-all approach is a recipe for failure. The right model is a deliberate choice, a blueprint carefully drawn to align with specific products, markets, and corporate objectives, providing the structure needed to compete and win.

The 6 Core Supply Chain Models

While countless custom variations exist, nearly every effective supply chain is built upon the principles of six core models. Each is engineered to thrive under a different set of market conditions, catering to unique product types and customer expectations. Choosing the right one is the first step toward operational excellence.

The Continuous Flow Model

This model is all about stability. Built for high-volume, low-variation products, the Continuous Flow model is the engine of mature industries with highly predictable demand. Think of staple foods like sugar or flour, or the processing of raw materials where production runs nonstop. Its key characteristics are a streamlined, unvarying production schedule and the maintenance of minimal inventory. The entire system is fine-tuned for maximum efficiency and reliability, making it a powerful but inflexible workhorse.

The Fast Chain Model

When a product’s relevance can be measured in months or even weeks, speed is everything. The Fast Chain model is designed for products with short market life cycles, where getting from concept to customer in the shortest possible time is the primary goal. This is the domain of fast fashion and consumer electronics. It relies heavily on accurate forecasting to anticipate trends and on rapid, efficient turnarounds that bridge the gap between design and retail shelves before the trend fades.

The Efficient Chain Model

In hyper-competitive markets where price is the key battleground, the Efficient Chain model reigns supreme. Its single-minded focus is on cost reduction at every conceivable point. This model is ideal for industries like steel or cement manufacturing, where the product is a commodity and squeezing out fractions of a cent in cost translates to a significant competitive advantage. It achieves this through extreme optimization of end-to-end inventory management, large-batch production, and maximizing asset utilization.

The Agile Model

Volatility is the enemy of efficiency but the natural habitat of the Agile model. This framework is engineered to respond rapidly to unpredictable demand and sudden market shifts. Unlike the Efficient model, it prioritizes flexibility over cost, making it perfect for specialized or custom-configured products where demand is difficult to forecast. To achieve this responsiveness, the Agile model relies on real-time data from the market and often maintains a buffer inventory of crucial components, not finished goods, to enable a quick final assembly once an order is placed.

The Custom-Configured Model

The Custom-Configured model offers a hybrid approach, elegantly blending the principles of Agile and Continuous Flow. It’s the standard for products that come with a multitude of configurations, such as automobiles or personal computers. Here, the upstream part of the chain operates on a continuous flow basis, producing and stocking base components in high volume. The downstream part, however, is purely agile, with the final assembly and configuration process triggered only after a specific customer order is received.

The Flexible Model

Some businesses face a unique challenge: long periods of low activity punctuated by intense bursts of high demand. The Flexible model is designed specifically to manage this volatility. It provides the capacity to quickly reconfigure manufacturing and logistics operations to handle these peaks and then scale back down without incurring massive overhead. This makes it essential for industries with pronounced seasonal demand, such as those producing holiday decorations, certain agricultural products, or specific types of apparel.

Strategic Approaches and Philosophies

These core models do not operate in a vacuum. They are implemented through broader strategic philosophies that guide how the supply chain functions. These principles shape the mindset of the organization and directly influence which operational model is the most appropriate fit.

Push vs. Pull Strategies

At the most fundamental level, supply chains are driven by one of two strategic triggers. A Push strategy is built on anticipation. Production and inventory levels are based on forecasts of future demand, with products “pushed” down the chain toward the consumer. This make-to-stock approach is common in Efficient and Continuous Flow models where predictability is high.

Conversely, a Pull strategy is triggered by actual demand. Nothing is made or moved until a customer places an order. This make-to-order approach minimizes inventory risk but requires extreme responsiveness, making it the foundation of Agile and Custom-Configured models.

Lean, Agile, and Leagile Management

Beyond Push and Pull, several management philosophies inform supply chain design. Lean management is a philosophy obsessed with the elimination of all forms of waste (time, materials, steps) to maximize value for the customer. It is the ideological partner of the Efficient Chain model.

Agile SCM, on the other hand, is a philosophy centered on flexibility and the ability to respond swiftly to a volatile marketplace. It values market sensitivity and virtual integration over pure cost efficiency.

The “Leagile” concept emerges as a powerful hybrid. This approach uses a strategic decoupling point to separate the supply chain into two parts. The upstream portion, which deals with predictable components, is managed using lean principles. The downstream portion, closer to the unpredictable customer, is managed using agile processes. This allows a business to gain the cost benefits of lean production while retaining the responsiveness of an agile system.

Key Frameworks for SCM Analysis

In addition to models and strategies, a set of standardized frameworks helps businesses analyze, measure, and optimize their supply chain operations. These are not operational models themselves but rather diagnostic tools designed to improve whatever model is in place.

The SCOR Model (Supply Chain Operations Reference)

The SCOR model is a globally recognized and standardized framework for analyzing and improving supply chain performance. It breaks down the supply chain into six core management processes: Plan, Source, Make, Deliver, Return, and Enable. By using a common vocabulary and standard metrics, the SCOR model allows companies to diagnose performance issues, benchmark themselves against competitors, and systematically optimize the effectiveness of any of the six supply chain models.

Other Notable Frameworks (GSCF and APQC)

While SCOR is prominent, other frameworks offer valuable perspectives. The Global Supply Chain Forum (GSCF) model focuses heavily on cross-functional business processes and the critical importance of relationship management with key suppliers and customers. The APQC Process Classification Framework (PCF) provides a comprehensive taxonomy of business processes, including those in the supply chain, that is widely used for benchmarking and process improvement initiatives.

Supply Chain Management (SCM) Models

While supply chain models focus on the flow of goods and services, supply chain management (SCM) models provide frameworks and methodologies for optimizing and coordinating various supply chain activities. These models offer structured approaches to planning, executing, and monitoring supply chain processes, enabling businesses to achieve greater efficiency, responsiveness, and profitability.

Integrated Model

The integrated supply chain model aims to create a seamless flow of materials, information, and financial transactions, enabling greater visibility, responsiveness, and optimization of the overall supply chain. It promotes the sharing of information, resources, and decision-making processes, emphasizing collaboration and coordination among all members of the supply chain, including suppliers, manufacturers, distributors, and retailers.

SCOR Model (Supply Chain Operations Reference)

The Supply Chain Operations Reference (SCOR) model, consisting of five core processes: Plan, Source, Make, Deliver, and Return, is a widely adopted framework for analyzing and improving supply chain performance and provides a standardized approach to defining, measuring, and optimizing supply chain processes. It enables businesses to benchmark their supply chain operations against industry best practices, identify areas for improvement, and implement strategies to enhance overall supply chain effectiveness.

Just-In-Time (JIT) Model

The Just-In-Time (JIT) model is a lean manufacturing principle that aims to reduce inventory levels and improve operational efficiency by receiving materials and components only as they are needed for production. JIT relies on close coordination with suppliers, precise demand forecasting, and efficient logistics to minimize excess inventory and associated carrying costs. Waste is minimized, storage costs reduced and a continuous flow of goods through the supply chain is promoted.

Read more on the Just in time model in our dedicated article:

Mass Customization Model

The mass customization model combines the principles of mass production with the ability to customize products according to individual customer preferences. It leverages flexible manufacturing processes, modular product designs, and advanced supply chain management techniques to enable the cost-effective production of customized goods and services on a large scale. This model is particularly relevant in industries such as consumer electronics, automotive, and apparel, where customers demand personalized products without compromising on cost or delivery times.

How to Choose the Right Model for Your Business

Selecting the right supply chain model is not an operational tactic; it is a critical strategic decision. The choice must be a deliberate one, born from a thorough analysis of the unique characteristics of your business and market.

The process begins by aligning the model with your overarching business strategy. Are you competing on cost, innovation, or customer service? Your answer will point you toward efficiency, speed, or responsiveness. Consider your product characteristics—a commodity like grain demands a different model than a highly customized piece of equipment. Analyze your market’s demand patterns. Is demand stable and predictable, or is it volatile and seasonal? Finally, understand where your product is in its life cycle, as a new launch may require an Agile approach that later evolves into a more Efficient model as the market matures.

Ultimately, the decision involves navigating the critical trade-off between cost, speed, and responsiveness. The technology and infrastructure you have in place will also enable some models while constraining others. By carefully weighing these factors, a business can move beyond a reactive operational stance and architect a supply chain that serves as a powerful, proactive engine for growth.

Advantages and Challenges of Supply Chain Models

Although adopting an effective supply chain model can significantly enhance a company’s competitiveness, profitability, and customer satisfaction, the implementation and maintenance may also present various challenges.

Benefits of Effective Models

There are numerous advantages to implementing an appropriate, well-designed supply chain model. Overall operational efficiency and productivity can be significantly improved by streamlining processes, reducing waste, and optimizing resource utilization. Timely delivery, product availability, and the ability to meet customer expectations will enhance customer satisfaction. Models that emphasize lean practices, waste reduction, and inventory optimization can lead to substantial cost savings, improving profitability, while green supply chain models reduce the environmental impact of business operations and contribute to long-term sustainability. Agile and flexible models enable companies to quickly adapt to changing market conditions, customer demands, and disruptions, providing a competitive advantage in dynamic environments. By implementing contingency plans and diversifying supply sources, potential risks, such as supply disruptions, quality issues, or regulatory changes can be identified and mitigated.

Common Challenges and How to Address Them

Despite the numerous benefits, implementing and maintaining effective supply chain models can present various challenges that businesses must address. As supply chains become increasingly global and interconnected, managing the complexity of multiple tiers of suppliers, logistics networks, and regulatory requirements can be a significant challenge. Employing advanced technologies, such as supply chain management software and data analytics, can help businesses gain greater visibility and control over their supply chain operations. Effective supply chain management often requires collaboration and information sharing among multiple stakeholders. Establishing strong partnerships, fostering trust, and implementing robust communication channels are essential to overcome this challenge. Effective change in management strategies, including employee training, clear communication, and incentives, can help mitigate resistance to the implementation of a new model and the process changes and cultural shifts that it may involve, facilitating a smoother transition. Integrating various technology systems, such as enterprise resource planning (ERP), transportation management systems (TMS), and warehouse management systems (WMS), can be challenging due to compatibility issues and data silos. This can be addressed by adopting standardized data formats, interoperability protocols, and cloud-based solutions. Implementing robust risk management strategies, such as diversifying supply sources, maintaining contingency plans, and investing in supply chain resilience, can help businesses mitigate the impact of possible disruptions caused by various risks such as natural disasters, geopolitical conflicts, and cybersecurity threats. As the implementation and management of effective supply chain models often require specialized skills and expertise, investing in talent development, training programs, and collaborative partnerships with academic institutions or industry associations are important to address the supply chain talent gap. A proactive approach to challenges and continuous improvement in supply chain operations will allow businesses to maximize the benefits of their chosen supply chain models and maintain a competitive edge in their respective markets.

Future Trends in Supply Chain Models

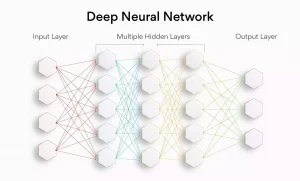

Impact of Artificial Intelligence and Blockchain

Emerging technologies such as artificial intelligence (AI) and blockchain are poised to revolutionize supply chain models in the coming years. AI algorithms can analyze vast amounts of data from various sources to provide predictive insights, optimize supply chain processes, and enhance decision-making capabilities. Machine learning techniques can improve demand forecasting, inventory management, and route optimization, leading to increased efficiency and cost savings. Blockchain technology, with its decentralized and transparent nature, has the potential to transform supply chain traceability and transparency. By creating an immutable record of transactions and product movements, blockchain can enhance supply chain visibility, streamline documentation processes, and facilitate trust among supply chain partners. This technology can be particularly beneficial in industries with complex supply chains, such as food, pharmaceuticals, and luxury goods, where traceability and provenance are crucial.

Digitalization and Automation

The digitalization and automation of supply chain processes are becoming increasingly prevalent, driven by the need for greater efficiency, agility, and cost optimization. Digital technologies, such as the Internet of Things (IoT), advanced robotics, and autonomous vehicles, are enabling real-time monitoring, automated material handling, and optimized logistics operations. Automated warehouses, equipped with robotics and autonomous guided vehicles (AGVs), can significantly improve picking, packing, and inventory management processes, reducing labor costs and minimizing human error. Similarly, autonomous trucks and drones can revolutionize last-mile delivery, offering faster and more efficient transportation of goods. Furthermore, the integration of digital twins – virtual replicas of physical supply chain assets and processes – can facilitate simulations, scenario planning, and predictive maintenance, enabling proactive decision-making and minimizing downtime. As these technological advancements continue to evolve, supply chain models will need to adapt and leverage these capabilities to remain competitive and meet the ever-increasing demands of customers and stakeholders.

Why Supply Chain Planning Models are Important

In today’s globalized and highly competitive business environment, the effective management of supply chains has become a critical success factor for companies across industries. Selecting and implementing the appropriate supply chain model is crucial for achieving operational excellence, meeting customer expectations, and maintaining a sustainable competitive advantage. Supply chain planning models provide a structured framework for businesses to align their supply chain strategies with their overall business objectives. By carefully considering factors such as product characteristics, demand patterns, customer requirements, and market dynamics, companies can choose the most suitable supply chain model to optimize their operations, reduce costs, and enhance customer satisfaction. Moreover, supply chain planning models offer a roadmap for effective implementation, enabling businesses to navigate the complexities of supply chain transformation. They provide guidance on integrating technology, streamlining processes, and fostering collaboration among supply chain partners, ensuring a seamless transition to the new supply chain model. Effective supply chain planning models also facilitate risk mitigation and supply chain resilience. By incorporating contingency plans and leveraging advanced technologies like artificial intelligence and blockchain, businesses can proactively identify and mitigate potential disruptions, ensuring business continuity and maintaining a competitive edge.

In an increasingly globalized and interconnected world, supply chain management has become a strategic imperative for businesses. Adopting the appropriate supply chain planning model can drive operational efficiency, enhance customer satisfaction, and ultimately contribute to long-term profitability and sustainable growth.

Learn how Intuendi AI can improve your supply chain management.