For any business with objectives to thrive in a rapidly evolving landscape, procurement and supply chain management are the keys to staying competitive. These interconnected functions ensure companies secure the right resources at optimal costs while transforming and delivering them efficiently to meet market demands. This guide offers a deep dive into procurement and SCM, exploring core concepts, technology, risk management, and future trends. With an intention to master these pillars, businesses can drive efficiency, reduce costs, and deliver superior value, ultimately achieving operational excellence in an evolving market.

What is Purchase and Supply Chain Management?

Procurement and supply chain management (SCM) are vital functions that fuel a company’s efficiency and success. Procurement focuses on acquiring goods and services at the best price and quality, while SCM oversees the entire journey of these goods—from suppliers to consumers. Mastering both functions is key to staying competitive, cutting costs, boosting quality, and enhancing customer satisfaction. This article delves into how procurement and SCM work together, the technologies shaping their future, and strategies to optimise operations, driving business excellence and long-term success.

Understanding Procurement

Procurement is the backbone of an organisation’s operations, ensuring that essential goods and services are acquired efficiently and at the best possible cost and quality. From sourcing reliable suppliers to negotiating contracts and managing logistics, procurement supports both strategic goals and day-to-day operations. Its impact is far-reaching, influencing cost structures, operational efficiency, and supplier relationships. By streamlining processes and leveraging automation, organisations can boost efficiency, reduce costs, and focus on long-term strategies like supplier development and risk management. Ultimately, effective procurement drives a company’s competitiveness and success.

Understanding Supply Chain Management

Supply Chain Management (SCM) is the strategic coordination of all activities involved in sourcing, procurement, production, and logistics to ensure seamless operations from raw materials to the final customer. It focuses on optimising efficiency, reducing costs, and enhancing customer satisfaction by ensuring products are delivered at the right time, place, and cost. Key players, including suppliers, manufacturers, and distributors, work together to streamline the process. Effective SCM not only boosts product quality and responsiveness to market changes but also strengthens supplier relationships and cuts operational costs, making it essential for business success and competitiveness.

Integration of Purchasing and SCM

Integrating purchasing and supply chain management (SCM) is essential for boosting efficiency and delivering superior business results. When procurement strategies align with SCM, the entire supply chain becomes more cohesive, driving improvements in quality, cost reduction, and delivery speed. This synergy streamlines processes, eliminates redundancies, and ensures resources are used optimally—preventing delays and disruptions. Close collaboration between procurement and SCM, through regular communication and joint decision-making, optimises transportation, demand forecasting, and resource planning.

The benefits of this integration extend to improved quality and reduced costs, as procurement ensures materials meet quality standards while leveraging bulk purchasing for better pricing. Coordinated efforts also lead to faster delivery times, enhancing customer satisfaction and giving businesses a competitive edge. Essentially, integrating purchasing and SCM is the key to operational excellence, ensuring efficiency, cost savings, superior quality, and quicker delivery—driving both performance and competitiveness.

Differences between Procurement and SCM

Understanding the distinction between procurement and supply chain management (SCM) is vital for recognising their unique contributions to business success. While procurement focuses on acquiring the right goods and services at the best price, SCM oversees the entire flow of goods, information, and finances from supplier to customer. Procurement is all about sourcing, supplier selection, contract negotiation, and purchasing, with the aim of securing high-quality materials, managing risks, and achieving cost savings. SCM, on the other hand, extends beyond procurement, coordinating everything from production to logistics and distribution, aiming to optimise efficiency, reduce costs, and ensure customer satisfaction.

While procurement zeroes in on supplier relationships and cost-effective purchasing, SCM takes a holistic approach, ensuring the seamless integration of all supply chain elements to deliver value to the customer. A commitment to understanding and leveraging these distinct functions aids businesses in enhancing both operational efficiency and strategic success.

Integration is the gateway into synchronised and streamlined processes across various divisions of any business. Manage your integrations with ease.

Procurement’s Role in SCM

Procurement is the cornerstone of Supply Chain Management (SCM), initiating the flow of materials and services that fuel production and ultimately reach customers. Its role is vital in ensuring quality, reliability, and cost-efficiency, all of which are key to a successful supply chain.At its core, procurement is responsible for selecting and evaluating suppliers. By building strong relationships with reliable partners, it guarantees a steady supply of high-quality materials, reducing risks of production delays. Effective contract management further enhances this by negotiating favourable terms, monitoring performance, and fostering long-term collaborations, which mitigate risks and improve supplier relations.

Cost management is another critical aspect, where procurement identifies savings through strategic sourcing, bulk purchases, and supplier partnerships, ensuring the organisation maximises value. Additionally, procurement plays a key role in supporting production by ensuring timely material availability, preventing delays, and influencing inventory and logistics strategies. In summary, procurement drives the overall success of the supply chain by securing the right resources at the right time, cost, and quality, leading to enhanced efficiency, reduced costs, and improved customer satisfaction.

How Procurement Fits into SCM

Procurement is the bedrock of Supply Chain Management (SCM), shaping every subsequent stage in the chain and influencing efficiency, costs, and delivery times. As the gateway through which materials and services enter the supply chain, effective procurement ensures that high-quality inputs are sourced cost-effectively and delivered on time, preventing bottlenecks and enabling smooth production and distribution. Procurement plays a crucial role in controlling supply chain costs. Through a facilitation process of negotiating favourable terms and strategically sourcing suppliers who offer the best value, it helps reduce costs and improve profit margins, allowing reinvestment into logistics and inventory management for greater efficiency. Its coordination with production ensures timely material delivery, while collaboration with logistics optimises transportation and storage, balancing cost and delivery schedules.

When procurement and SCM functions work together seamlessly, businesses gain flexibility, agility, and the ability to respond quickly to market shifts—key to staying competitive. This integrated approach also fosters stronger supplier relationships, driving collaboration and innovation. In essence, procurement is a critical pillar of SCM, shaping the efficiency, cost-effectiveness, and responsiveness of the entire supply chain and underscoring the need for coordinated management to drive overall success and competitiveness.

Interconnectedness of Procurement and SCM

The synergy between procurement and supply chain management (SCM) is essential for a seamless and efficient business operation. When these strategies are aligned, companies unlock efficiencies, reduce costs, and fuel innovation, fostering growth and sustainability.

Collaboration between procurement and SCM enhances efficiency by synchronising demand forecasting with production schedules and inventory levels. This reduces lead times, stockouts, and excess inventory, resulting in a more agile and responsive supply chain. The joint approach also drives cost reductions, from bulk purchasing and better payment terms to implementing cost-saving innovations with suppliers, which can be reinvested in areas like logistics or technology, further boosting performance.

Supplier relationships thrive when procurement and SCM work in harmony. Strong partnerships ensure a reliable flow of high-quality materials and services, sparking collaborative efforts in product development, quality improvement, and sustainability. Together, procurement and SCM can also proactively manage risks, identifying potential threats and creating contingency plans to protect supply chain continuity.

This partnership drives innovation as well. By leveraging shared insights and embracing new technologies like automation and data analytics, procurement and SCM improve supply chain visibility and decision-making, staying ahead of market trends and adapting to evolving consumer needs. Sustainability, a growing priority, also benefits from their collaboration. Through aligning strategies, companies can adopt eco-friendly sourcing, reduce waste, and minimise environmental impact, balancing profitability with social and environmental responsibility.

Ultimately, the integration of procurement and SCM generates synergies that enhance efficiency, lower costs, strengthen supplier ties, mitigate risks, foster innovation, and promote sustainability, securing long-term business resilience and success.

Technology in Purchase and SCM

Technology has become a critical force in transforming purchasing and supply chain management (SCM), driving efficiency, accuracy, and competitiveness. Tools such as Enterprise Resource Planning (ERP) systems, specialised procurement software, automation, and data analytics are revolutionising how businesses operate their supply chains.

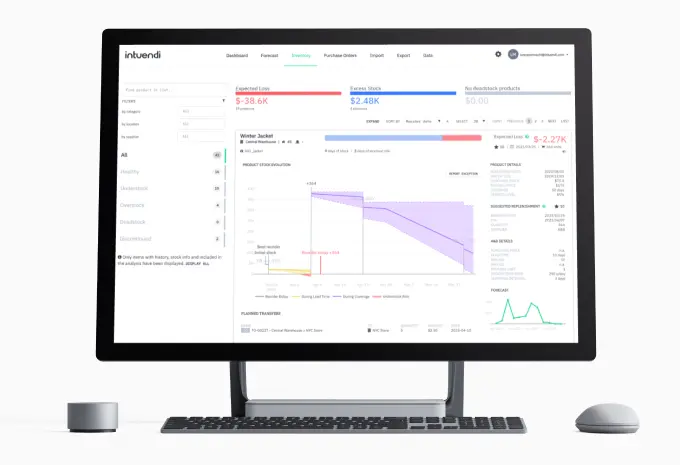

ERP systems integrate procurement with production, logistics, and finance, creating real-time, centralised data that streamlines processes and reduces errors. Specialised procurement software enhances supplier management and automates routine tasks, boosting accuracy and saving time. Meanwhile, automation technologies like robotic process automation (RPA) and artificial intelligence (AI) take over repetitive tasks and provide deeper insights into market trends and supplier performance, empowering smarter decision-making.

Data analytics plays a pivotal role, offering actionable insights into supply chain performance, predictive forecasting, and risk management, helping businesses optimise strategies and improve supplier relationships. Emerging technologies like blockchain, the Internet of Things (IoT), and machine learning promise even greater innovations, enhancing transparency, tracking, and process optimisation. In today’s fast-paced business world, leveraging technology is no longer a choice—it’s a necessity. Those who embrace it are positioned to build resilient, agile, and competitive supply chains, poised to thrive in a complex and ever-changing landscape.

Data Holds Secrets—discover them with Predictive Analytics today! Gain insights from AI-powered planning and the experts at Intuendi.

Risk Management in Purchasing and SCM

Risk management is a cornerstone of purchasing and supply chain management (SCM), ensuring the continuity and reliability of operations. Identifying potential risks and creating proactive strategies are meant by which businesses can safeguard their supply chains from disruptions.

The first step is recognising both internal and external risks, from operational inefficiencies to geopolitical instability or supplier insolvency. A thorough risk assessment helps prioritise these threats. Key to this is evaluating supplier reliability, conducting regular audits, and diversifying the supplier base to avoid over-reliance on any single source, thus minimising disruption. Contingency planning is crucial for handling unexpected challenges like natural disasters or supplier failures. These plans might involve alternative suppliers, safety stock, or flexible logistics, allowing companies to react swiftly and limit disruptions. Additionally, technologies like predictive analytics and IoT devices can help companies detect risks early by offering real-time insights and forecasts.

Collaboration is also vital. Strong supplier relationships and open communication foster joint risk mitigation strategies, sharing the burden and building a more resilient supply chain. In essence, effective risk management in procurement and SCM not only protects operations but also strengthens overall business resilience, competitiveness, and stability, ensuring companies can weather disruptions and thrive in a dynamic market.

Sustainability in Purchasing and SCM

Sustainability is now a central pillar in purchasing and supply chain management (SCM), as businesses strive to balance profitability with social and environmental responsibility. By integrating sustainable practices, companies can reduce their environmental footprint, champion ethical sourcing, and elevate social responsibility across their supply chains. These efforts not only support long-term business success but also strengthen corporate reputation, as consumers and stakeholders increasingly value eco-conscious and ethical operations. Embracing sustainability in SCM isn’t just a moral imperative—it’s a strategic advantage that paves the way for a more resilient, future-ready business.

Ethical Sourcing and Its Importance

Ethical sourcing is the practice of procuring goods and services responsibly, ensuring that suppliers follow fair labour practices, provide safe working conditions, and respect human rights. Companies must perform due diligence through audits, certifications, and transparent reporting to verify compliance. By prioritising ethical sourcing, businesses can avoid risks like labour abuses, legal issues, and reputational harm, while contributing to global social standards.

Minimising Environmental Impact

Procurement and SCM are key to reducing a company’s environmental footprint through sustainable practices. This includes selecting suppliers who minimise waste, reduce emissions, and conserve resources. Companies can achieve this by sourcing renewable or recyclable materials, optimising logistics with eco-friendly packaging, consolidating shipments, and using energy-efficient transportation. Adopting a circular economy approach, where products are designed for reuse, refurbishment, or recycling, further helps reduce waste and resource consumption.

Social Responsibility in Procurement and SCM

Social responsibility in procurement goes beyond ethical sourcing, encompassing community engagement and support. Companies can enhance local well-being by ensuring fair labour practices, supporting local suppliers, and participating in community development. This may involve partnerships with local businesses, investing in projects, or offering worker training. Building strong relationships with communities fosters trust and support, contributing to a stable and resilient supply chain.

Balancing Economic, Social and Environmental Objectives

Sustainability in procurement and SCM involves balancing economic goals with social and environmental objectives, focusing on long-term impacts over short-term gains. Companies should integrate sustainability into their procurement policies, aligning these goals with overall business objectives. Businesses can track their sustainability progress and identify areas for improvement by measuring and reporting on metrics like carbon footprint, waste reduction, and social impact.

The Benefits of Sustainable Practices

Adopting sustainable practices in purchasing and SCM provides numerous benefits, including enhanced reputation, attraction of socially conscious consumers, and improved employee morale. Sustainable supply chains are more resilient, better equipped to handle regulatory changes, resource shortages, and social challenges. Additionally, sustainability initiatives lead to cost savings through greater efficiency, waste reduction, and resource conservation. Prioritising sustainability helps companies achieve long-term success while positively impacting society and the environment, balancing economic, social, and environmental responsibilities for a more sustainable future.

Performance Measurement in Purchase and SCM

Performance measurement is essential in purchasing and SCM to ensure strategies are effective and goals are met. Using key performance indicators (KPIs), businesses can track progress, identify improvement areas, and drive continuous enhancement.

Key Performance Indicators (KPIs) in Procurement and SCM

KPIs are key for measuring performance in procurement and SCM. In procurement, KPIs like cost savings, procurement cycle time, supplier performance, and contract compliance assess financial efficiency, process speed, supplier reliability, and adherence to agreements. In SCM, KPIs such as inventory turnover, order accuracy, delivery performance, and supply chain cost track inventory efficiency, fulfilment precision, delivery reliability, and overall supply chain expenses, helping identify cost-saving and improvement opportunities.

Benchmarking and Continuous Improvement

Benchmarking against industry standards helps businesses compare performance, identify gaps, and adopt strategies for improvement. Continuous improvement is key in procurement and SCM, with regular performance reviews and stakeholder feedback uncovering inefficiencies. Implementing methodologies like Lean, Six Sigma, and TQM drives process improvements, reduces waste, and enhances efficiency, enabling companies to stay competitive.

The Role of Technology in Performance Measurement

Technology enhances performance measurement by enabling data collection, analysis, and reporting through advanced analytics and business intelligence tools. These platforms offer real-time KPI monitoring, trend identification, and demand forecasting for proactive decision-making. Automated systems like ERP streamline data collection, reduce errors, and provide a comprehensive view of supply chain performance. Dashboards simplify data visualisation, helping managers take informed actions.

Strategic Goals and Performance Measurement

Aligning KPIs with strategic goals ensures performance measurement supports overall business objectives, such as customer satisfaction or cost reduction. Regularly reviewing and updating KPIs keeps them relevant to changing priorities and market conditions. Performance measurement in procurement and SCM drives continuous improvement, competitiveness, and responsiveness by employing KPIs, benchmarking, and leveraging technology.

Best Practices for Implementing Procurement and SCM

Integrating procurement and SCM is key to maximising efficiency and effectiveness. Seamless collaboration between both functions boosts performance, reduces costs, and enhances competitiveness. Implementing best practices for integration drives these improvements.

Collaborative Strategies for Integration

A key strategy for integrating procurement and SCM is fostering cross-departmental collaboration. By forming cross-functional teams from procurement, production, logistics, and finance, businesses can develop strategies aligned with overall goals. Regular communication and joint decision-making ensure all functions are united in pursuing common objectives.

Tools and Software Solutions

Integrated tools like ERP and procurement software are vital for seamless procurement and SCM integration, enabling real-time data sharing, collaboration, and coordination across departments. Features like automation, analytics, and reporting enhance supply chain visibility and control. Supplier Relationship Management (SRM) systems further support integration by managing supplier interactions, ensuring alignment with SCM objectives through evaluation, performance monitoring, and risk management.

Training and Professional Development

Investing in training for procurement and SCM professionals is key to successful integration, equipping them with skills in strategic sourcing, analytics, risk management, and software use. Continuous learning through certifications, workshops, and seminars ensures they stay updated on trends and best practices, fostering informed decision-making and collaboration.

Promoting a Culture of Integration

Promoting a culture of integration is essential for long-term success. Leadership fosters this by encouraging collaboration, innovation, and continuous improvement while providing support and resources. Recognising and rewarding contributions to integration further reinforces the value of teamwork and shared goals.

Measuring and Monitoring Integration Success

Regularly measuring integration success through KPIs like collaboration, efficiency, and cost savings is key for continuous improvement. Reviews, audits, and employee feedback help refine integration strategies and align efforts with business goals. In conclusion, integrating procurement and SCM enhances operational excellence and competitiveness. By fostering collaboration, using integrated tools, investing in training, promoting a supportive culture, and monitoring progress, businesses can ensure seamless cooperation and long-term success.

Future Trends in Purchase and SCM

The landscape of procurement and supply chain management (SCM) is rapidly evolving, driven by technological advancements like AI, machine learning, and blockchain, which enhance efficiency, transparency, and decision-making. AI-powered predictive analytics optimise inventory and forecast disruptions, while blockchain improves security and traceability in supply chains. Building resilient, diversified supply chains and adopting real-time monitoring via IoT ensures companies can swiftly adapt to challenges.

As automation, visibility, and collaboration become central to SCM, businesses that embrace these technologies will excel in a complex global market. Through vigorous efforts to leverage digital tools, foster innovation, and prioritise sustainability, companies can streamline operations, reduce costs, and deliver greater value to customers. In this dynamic future, the integration of procurement and SCM will drive long-term success and resilience, enabling companies to thrive amid new challenges and opportunities.

Turn Data into Gold with Intuendi!