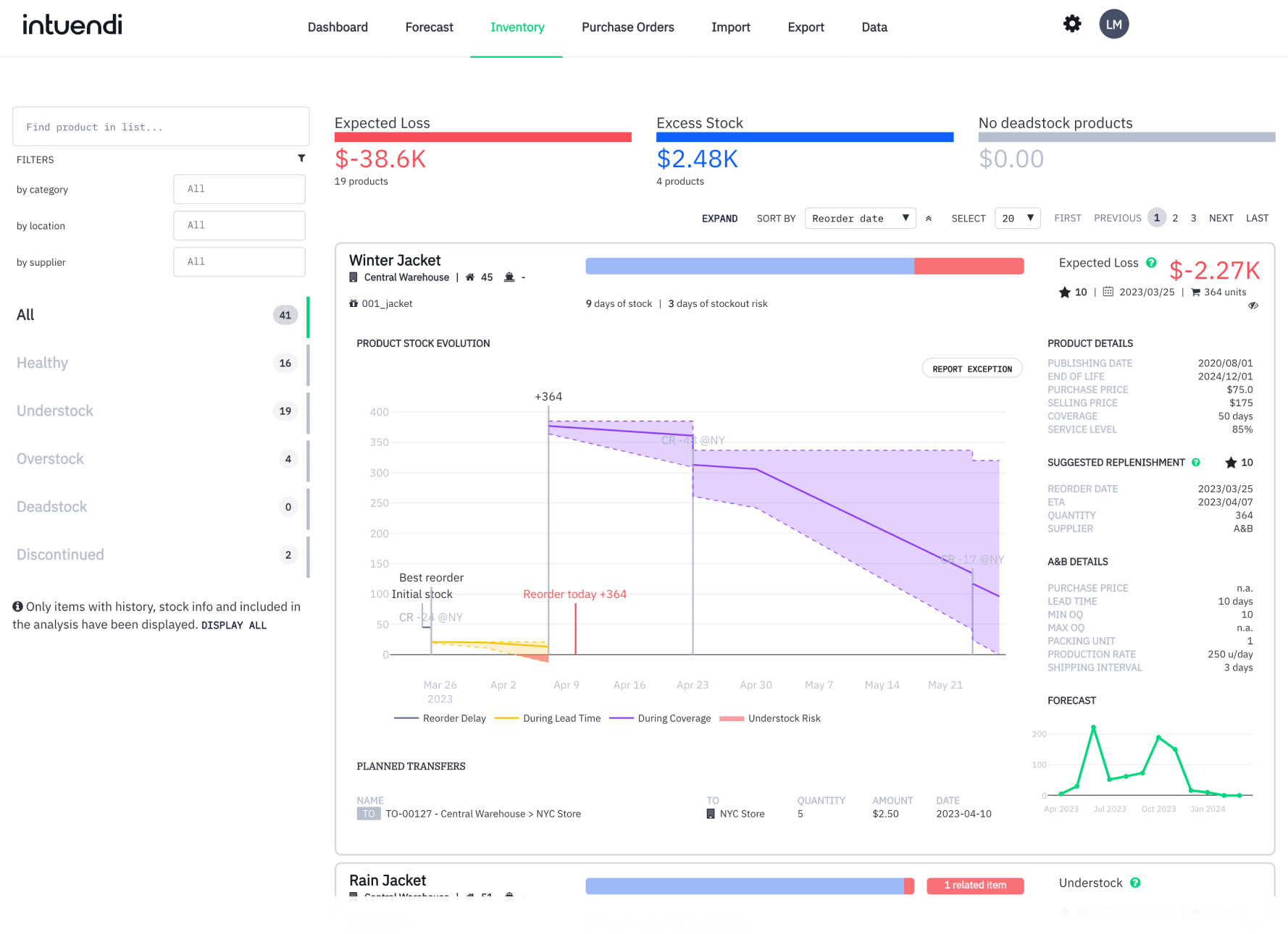

The above image provides a somewhat accurate depiction of a common issue in the supply chain and logistics industry: the excess of stock, often referred to as deadstock. The main problem surrounding deadstock is one that all businesses aim to avoid – the loss of money. This occurs in multiple forms, whether as a result of lost revenue from unsold products or taking up warehouse space that could be used for more high-selling, valuable products.

What is Deadstock?

Deadstock refers to merchandise or inventory that exists in warehouses and storage as a result of stock discontinuation, passing the expiry date, outdated and obsolete stock, or stock that remained unsold. The two leading factors causing an accumulation of deadstock are inaccurate sales forecasting and poor inventory management.

Various industries are affected by the issue of deadstock. It just takes shape in different forms, depending on the industry. In the food industry, unsold or expired products are the most common forms of deadstock, such as fruit, vegetables and baked goods. In the fashion industry, where trends and consumer preferences are constantly changing, unsold items of specific fabrics or colours are a fairly common occurrence. In the electronics industry, as more and more technological advances are being made, older product models become obsolete or discontinued, resulting in them becoming deadstock.

How to Calculate Deadstock

While deadstock might look different from industry to industry, its effects are fairly similar across the board. It is thus imperative that companies calculate their levels of deadstock, based on the type of business that is being run. There are a multitude of metrics and indicators that can be used to help measure the level of deadstock for a company, which may also provide insight on how to avoid it in the future:

Initial Stock Value: Initial stock value refers to the method of calculating deadstock based off of the difference between inventory before and after a specific period. The value of the deadstock is determined by subtracting the value of inventory sold during a specific period from the total value of the inventory at the beginning of a specific period. The difference is equal to the value of the deadstock. This method is useful for businesses that are relatively stable in their inventory value and quantities and do not experience significant fluctuations in demand.

Acquisition Cost: This refers to the total cost of the deadstock, which is calculated by determining the cost of purchasing the inventory and subtracting the value of the inventory sold during a specific period. Businesses that have a high turnover of inventory, experiencing fluctuations in demand are more likely to use the acquisition cost metric to calculate their deadstock.

Storage Cost: Companies experiencing high storage costs will use this metric to calculate deadstock. This involves determining the cost of storing inventory over a specific period and subtracting the value of the inventory sold during that time.

Duration of Unsold Product: By looking at how long a product remains unsold, deadstock can be calculated. After determining the amount of time a product has been in inventory, multiply this amount by the holding cost per unit. Deadstock products with limited shelf life or high risk of obsolescence will be calculated through the use of this metric.

As previously mentioned, one of the most considerable difficulties of deadstock is the loss of revenue. Not only is there the cost of acquiring inventory, but when sitting in a warehouse or in storage, holding costs such as insurance, maintenance and utilities become an unnecessary expense. Additionally, deadstock also takes up valuable storage space that could be used by more profitable and in-demand products. Trying to rid storage from deadstock may result in financial compromises such as offering discounts or promotions on the inventory, resulting in lower profit margins.

There are numerous reasons as to how deadstock can accumulate. This might include oversights on the part of a business, such as over-ordering and inaccurate sales forecasting. However, there are always external factors that are difficult to predict that affect deadstock levels. These may include economic downturns, supply chain disruptions, sudden changes in market trends and demand, or unexpected events (such as a global pandemic!)

How to Deal with Deadstock

Previously mentioned, deadstock is often sold through the adjustment of pricing through promotions, sales or discounts. There are, however, other viable tactics to help clear out deadstock while still generating revenue. In retail, dead stock can be sold to consignment and thrift stores. This is also a more eco-friendly way of reducing one’s excess stock. In wholesale, companies can look at the option of bundle sales – putting together a group of deadstock items and selling them as one, for a discounted price. How deadstock sales are marketed is also vital in clearing storage space from this inventory. It is, therefore, worthwhile for companies to look into effective marketing strategies and budgeting for deadstock items.

While it is important to know how to sell deadstock, it is arguably more important to assess how one can avoid it in the first place. Inaccurate sales forecasting can lead to oversights in decisions dealing with the demand of a products. Oftentimes, businesses will overestimate the demand for a particular product and will order more inventory than necessary. Over-ordering is one of the quickest ways to accumulate deadstock. Changes in market demand and preference of a certain product, coupled with a business’ failure to anticipate these changes, is linked to inaccurate sales and demand forecasting, and can therefore act as an aggravator for the accumulation of deadstock.

The above issues are more-likely to be avoided through the use of analysing historical data and monitoring market trends.

Inventory management software also serves to avoid the accumulation of deadstock, in that it aids in alerting a company to stock and inventory issues. Through identifying the problems sooner, inventory management software allows more time for the issues to be ironed out.

Are you interested in reducing the risk of deadstock for your products? Contact us today, we’ll be happy to give you our expert advice.