One of the most notable differentiating factors between your business achieving supply chain excellence or mediocrity is that of replenishment optimization. This is achieved when you perfectly balance the optimal quantity and timing of inventory items ordered to meet service levels and customer demand, while simultaneously keeping inventory levels and operational costs to a minimum. Should you believe that your business could benefit from a strengthened replenishment optimization process, then you have come to the right place! We will be looking at all of the ins and outs of replenishment optimization: its benefits, the practical implementation thereof, the essential features needed in an automated replenishment system, technology and replenishment optimization, and why replenishment optimization is crucial for the management of any supply chain. Let’s begin!

What is Replenishment Optimization?

The primary goal of replenishment optimization is to calculate the optimal time at which to order inventory items while also taking into account the lead times, demand expectancy, service levels, and costs. Unsurprisingly, this is most often completed with the application of mathematical models and algorithms, allowing you to carefully balance the trade-off between holding or stock-out costs with demand variability and capacity limitations. It can be applied to various types of inventory, such as raw materials and spare parts, as well as at different levels within the supply chain such as manufacturers, retailers, etc. The importance of inventory replenishment cannot be emphasized enough as it can have a weighty effect on inventory performance and customer satisfaction. By keeping stock levels optimal, businesses spend less on warehouse space, insurance, and overall inventory holding costs. Above and beyond this, ordering costs can be reduced as

When ordering optimally, one’s transportation, handling, and administrative costs are also kept to a minimum. Furthermore, you will also be able to improve and increase your inventory turnover, service level, and ultimately, customer satisfaction. Replenishment optimization also benefits the performance of the supply chain as a whole. By sharing precise, well-timed information, replenishment optimization aids in aligning with your supply chain partners on various replenishment policies and objectives. Alignment makes the supply chain more responsive and agile, thereby helping to nullify demand variability and prevent the bullwhip effect. You then find yourself with a more resilient and sustainable supply chain, which reduces risk exposure and environmental impact.

Benefits of Replenishment Optimization

We have already discussed some of the benefits a business can gain from replenishment optimization. Moving forward, let us hone this knowledge by taking a look at the top five benefits of automated replenishment optimization. This can be referred to as the use of tools and software systems that will automate and optimize the whole replenishment process.

Reduced Operational Costs

An automated system can significantly reduce operational costs by using advanced data analysis and algorithms. It takes factors such as demand patterns, supply chain constraints, etc., and uses them to calculate optimal replenishment parameters for each inventory item. The result can increase productivity and efficiency, as well as savings in holding, stock-out, and ordering costs. A study by Gartner found that in some cases automated replenishment optimization reduced inventory holding costs by 10-30%, ordering costs by 10-20%, and stock-out costs by 5-15%. What company wouldn’t want to improve their profits by such fantastic margins?

Lower Stock Levels

Automated replenishment optimization can estimate optimal inventory levels and future demand for each inventory item. Through the use of highly advanced optimization and forecasting techniques, you can lower your stock levels while still maintaining high service levels. This prevents over and understocking of items, increasing profitability and improving cash flow. A case study by E2open found that automated replenishment optimization can reduce the average inventory level by 15-25%, while maintaining or improving service levels.

Improved Inventory Turnover

A key indicator of inventory efficiency is inventory turnover. An automated system can improve inventory turnover by making use of the best rules and policies. This means that by replacing inventory at the right time and with the right quantity to match customer demand, you can increase sales, improve customer satisfaction, and reduce inventory becoming obsolete. A case study by ToolsGroup found that automated replenishment optimization can increase inventory turnover by 10-30% while achieving a service level of 99% or higher.

Higher Service Levels

The all-important customer satisfaction and loyalty can be increased significantly by automated replenishment optimization. With the use of adaptive replenishment strategies, an automated system can help you better manage demand uncertainty and variability, ensuring items are always available. This means you can provide a higher service level, thus increasing customer retention and referrals.

Enhanced Exception Management

Exception management is the ability to manage any abnormal or unexpected situation that may affect the replenishment process. An automated system uses an alert system to prioritize any inventory that requires special intervention to prevent supply shortages. This results in faster problem-solving and decision-making.

Practical Implementation

Like most processes, there is always the risk of challenges, and in this case, most often in strategic and technical aspects of implementing a replenishment optimization system. Fret not, as we have some practical steps for you to follow to help you overcome these challenges:

- Define your objectives, such as cost reduction goals, service level targets, inventory items, etc.

- Assess your current inventory levels, service levels, demand patterns, etc.

- Select the software best suited to your business based on its features, usability, and affordability.

- Collect all the data you need for your replenishment optimization process, such as the costs and constraints, historical data, etc.

- Customize your chosen system to fit your specific business needs, such as your replenishment methods and parameters.

- Test the accuracy and effectiveness of your system by using simulated or real data across various scenarios.

- Monitor your system with the use of control mechanisms and feedback.

- Evaluate the replenishment optimization system with the use of certain benchmarks to measure its results and benefits. This will help you identify and implement any possible improvements.

Essential Features of an Automated Replenishment System

To further mitigate the risk of ample challenges, there are, additionally, some essential features that any automated replenishment system should possess. Firstly, demand forecasting is essential. It must be able to predict future demand for your inventory items accurately. It does this by using statistical and machine learning methods to include demand variability and uncertainty, while also incorporating demand influences such as trends and seasonality. Secondly, it must be able to optimize your inventory. It does this by ascertaining the optimal level of each inventory item while taking into account the demand forecast, the service level, the lead time, and the cost. The optimal inventory level consists of base stock, which is the average inventory level needed to cover the average demand, and the safety stock level, which is the extra inventory level needed to cover any demand variables. This feature uses various methods to calculate the ideal base stock and safety stock levels. These methods include the newsvendor model, the service level model, the fill rate model, etc.

The third essential feature is that of replenishment optimization. This enables it to pinpoint the optimal replenishment decision for each and every item while taking into account the lead time, demand forecast, costs, and service level. The decision consists of two variables: the reorder point, which is the inventory level at which an order should be placed, and the reorder quantity, which is the amount of inventory that should be ordered. The system can calculate these two variables by several methods, such as the economic order quantity (EOQ) model, the periodic review model, the continuous review mode, etc. The fourth feature to look out for is exception management. This feature alerts you when there are any deviations from the normal replenishment process, such as spikes in demand, or supply shortages. It also helps you decide on what actions to take to solve the situation by perhaps adjusting replenishment parameters, reallocation inventory, etc.

The fifth feature to look out for is performance measurement. This helps you improve the efficiency of the replenishment process by evaluating indicators such as inventory turnover, service levels, inventory value, etc. It collects data and provides insight on how best to improve your replenishment process, by highlighting best practices and areas of improvement. The last feature your system should possess is integration and collaboration. Your replenishment system has to be able to connect with other systems, such as production planning, sales planning, the warehouse and transportation management system, etc. This ability to integrate allows the exchange of data which enables you to align your systems and processes, as well as those of your suppliers and distributors.

Technology and Replenishment Optimization

The benefits of technology in replenishment optimization are exponential! Its capabilities and functionalities provide accuracy that would, otherwise, be impossible. Let’s explore some of the technological solutions that can support the replenishment optimization process:

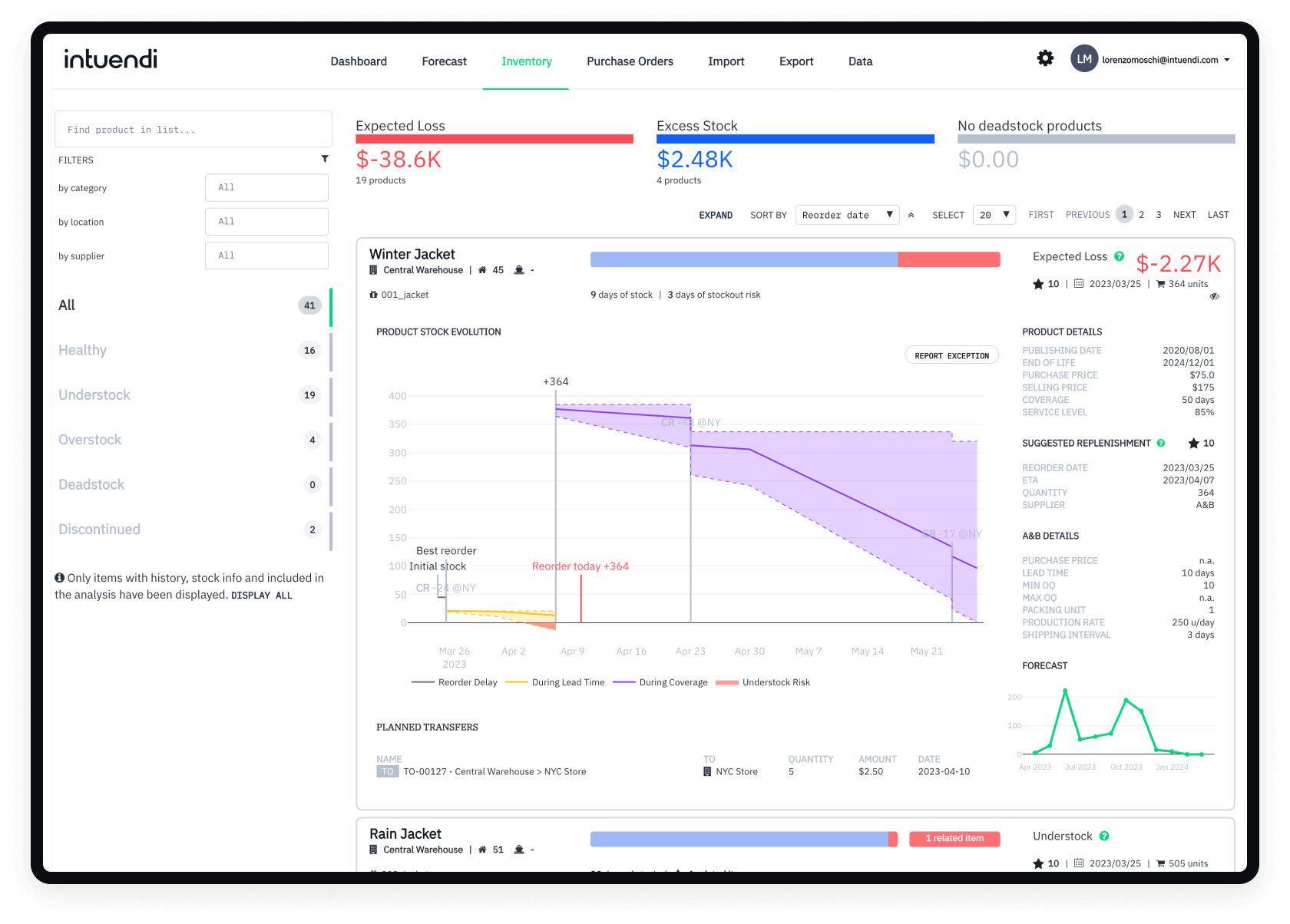

- Software systems and tools: These software applications automate and optimize the replenishment process by using sophisticated algorithms and data analysis. Examples include Kinaxis, Reflex Solution, and of course Intuendi.

- Cloud computing and big data: This allows for the storage, processing, and analysis of huge and complex data sets. It also makes it possible to integrate various types of data, such as historical, real-time, etc. It enables you to apply sophisticated forecasting and optimization techniques, such as machine learning, and artificial intelligence.

- Internet of Things (IoT) and radio frequency (RFID): These enable physical objects and devices to communicate with the use of tags and sensors. They provide visibility and traceability of inventory items, as well as the automation of replenishment actions, such as shipping, ordering, receiving, etc.

- Blockchain and smart contracts: This technology allows one to securely share information among supply chain partners using encrypted ledgers and protocols. It makes coordination and collaboration possible, as well as the verification and execution of replenishment agreements, such as prices, quantities, etc.

An example of a business that has had success in implementing technological solutions for replenishment optimization is Walmart. Their cloud-based system is able to analyze the inventory and demand data from over 11,000 stores and 100,000 suppliers and produces the optimal replenishment decisions for millions of products. This would be an impossible task without the use of machine learning and artificial intelligence. The system has helped Walmart to reduce inventory levels by 15%, increase service levels by 10%, and save $20 billion in operational costs. Another excellent example is Coca-Cola. Their replenishment optimization system is IoT-based and it monitors more than 16 million vending machines. With the use of tags and sensors, it triggers optimal replenishment actions. How else would it be possible to keep all their vending machines optimally stocked? This system has helped Coca-Cola to reduce stock-out incidents by 75%, increase sales by 12%, and improve customer satisfaction by 25%.

Maersk is a shipping company that makes use of a blockchain-based replenishment optimization system. They keep track of all their container shipments and transactions by using encrypted ledgers and smart contracts. This system has helped Maersk to reduce its paperwork and administration costs by 80%, increase transparency and security by 90%, and improve coordination and collaboration by 50%. But your company does not have to be the next Walmart or Coca-Cola to experience astronomical results by implementing these fantastic systems.

Intuendi published an excellent case study on how one customer aimed at pushing growth by increasing his catalog while maintaining a lean inventory:

Why is Replenishment Optimization crucial for supply chain management?

As we have now, hopefully, made abundantly clear, there are many benefits and advantages that replenishment optimization brings to supply chain management. If you are hoping to minimize your operational costs while maximizing profitability, then replenishment optimization is definitely for you. It will help you reduce your inventory holding costs, ordering costs, and stock-out costs while increasing your inventory turnover and cash flow. You will see enhanced customer satisfaction and loyalty as replenishment optimization increases your service level and fill rate. There will be improved coordination of the inventory operations due to the alignment of stock replenishment policies and objectives between supply chain partners, achieved by timely information and data sharing. Your inventory operations will be more agile and responsive because of reduced lead times, making it possible to better cope with demand variabilities or supply chain disruptions. It will also boost the sustainability of your inventory operations, by improving risk management and problem resolutions, and by minimizing risk exposure and environmental impact.

Replenishment optimization within supply chain management can help give a business a strategic advantage and competitive edge while creating value for both customers and stakeholders. This technical and strategic process requires the integration of technology, organization, and strategy. With the integration of a replenishment optimization system, a business can improve its inventory performance and its supply chain performance, and ultimately, its business performance. So, what are you waiting for?

Download our free eBook outlying how to mange both short-term replenishment and mid to long-term replenishment planning.