In today’s highly competitive and globalized business landscape, supply chain management has become a critical factor for companies seeking to optimize their operations, reduce costs, and enhance customer satisfaction. Traditional linear supply chain models are no longer sufficient to meet the ever-increasing demands of consumers and the complexities of modern commerce. This has led to the emergence of integrated supply chains, which offer a comprehensive and interconnected approach to managing the flow of goods, information, and finances from raw material sourcing to final product delivery.

What is Integrated Supply Chain?

An integrated supply chain is a strategic approach that seamlessly aligns and coordinates the various components and processes involved in the creation and distribution of products or services. It represents a shift from the traditional silo-based supply chain models, where each function operated independently, towards a collaborative and synchronized system that facilitates end-to-end visibility, communication, and decision-making.

The evolution from traditional supply chain models to integrated supply chains has been driven by several factors, including the globalization of markets, advancements in technology, and the need for increased efficiency and responsiveness. Companies have recognized the limitations of fragmented supply chains, where information silos, lack of coordination, and inefficiencies can lead to higher costs, longer lead times, and poor customer experiences.

Let us take a closer look at the primary goals and objectives of integrating a supply chain.

Processes are streamlined and redundancies are eliminated, improving overall operational efficiency. As a result, delivery times are faster, products are more readily available and the responsiveness to changing demands is enhanced. All this leads to increased customer satisfaction. As resource utilization is optimized and better demand forecasting is enabled, waste is minimized, leading to a reduction in costs. An integrated supply chain also looks at fostering collaboration and information sharing among all stakeholders, from suppliers to customers. This ultimately leads to increased agility and resilience to adapt to market changes, disruptions, and evolving customer preferences.

Several industries and companies have successfully implemented integrated supply chains, such as automotive giants like Toyota and Ford, retail giants like Walmart and Amazon, and technology companies like Apple and Samsung. These companies have leveraged integration to optimize their operations, reduce costs, and provide superior customer experiences.

Key Components of Supply Chain Integration

An integrated supply chain comprises several interconnected components that work together to ensure seamless and efficient operations. The procurement component involves the strategic sourcing and acquisition of raw materials, components, and services from suppliers. Effective procurement processes are essential for ensuring the timely availability of required inputs while managing costs and quality.

Production encompasses the manufacturing or assembly processes that transform raw materials and components into finished goods or products. It encompasses various activities such as production planning, scheduling, quality control, and inventory management. Distribution involves the efficient and timely movement of finished goods from the production facilities to various distribution centers, warehouses, or directly to customers. It includes transportation, warehousing, and logistics management.

Logistics encompasses the planning, implementation, and control of the forward and reverse flow of goods, services, and related information between the point of origin and the point of consumption. It involves activities such as transportation management, order processing, and returns handling. The key stakeholders in an integrated supply chain include suppliers, manufacturers, distributors, and customers. Effective communication and collaboration among these stakeholders are crucial for ensuring the smooth flow of materials, information, and finances throughout the supply chain. Each stakeholder plays a vital role in contributing to the overall efficiency and success of the integrated system.

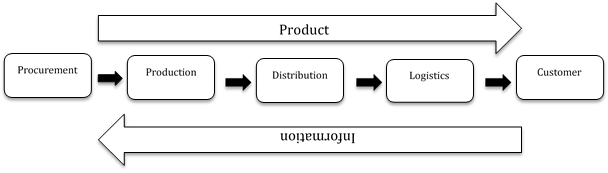

The importance of communication and collaboration among these components cannot be overstated. By fostering seamless information exchange, real-time data sharing, and centralized decision-making, companies can achieve greater visibility, responsiveness, and alignment across the entire supply chain. This integration enables proactive decision-making, rapid problem-solving, and the ability to quickly adapt to changing market conditions or customer demands. To illustrate the interconnected nature of these components, consider the following diagram:

How an Integrated Supply Chain Works

In order for companies to implement this process effectively, it is crucial that they have a clear understanding of how an integrated supply chain operates. This section will delve into the step-by-step process, highlighting the importance of real-time data sharing, centralized information systems, and the distinction between horizontal and vertical integration strategies.

The Process of an Integrated Supply Chain

The process of an integrated supply chain is a continuous cycle that begins with the acquisition of raw materials and ends with the delivery of finished products to customers. Let us discuss the key steps involved.

The process starts with the procurement of raw materials which involves identifying and sourcing the necessary raw materials or components from reliable suppliers. This is done through activities such as supplier evaluation, contract negotiation, and order placement. Production, planning, and scheduling follow. This is based on customer demand forecasts and inventory levels. Production plans are developed to ensure efficient use of resources and timely delivery of finished goods. The next step is manufacturing and assembly where raw materials and components are transformed into finished products through various manufacturing processes, adhering to quality standards and production schedules.

Inventory management forms yet another important step. Finished goods are stored and managed in warehouses or distribution centers, with real-time tracking of inventory levels and optimized replenishment strategies. This goes along with order processing and fulfillment where customer orders are received, processed, and fulfilled through efficient picking, packing, and shipping processes, leveraging logistics and transportation networks. Finished products are then distributed and delivered. They are transported to their designated destinations, whether distribution centers, retail locations, or directly to customers, using optimized transportation routes and modes. After delivery, customer feedback is collected and analyzed to identify areas for improvement and address any issues or concerns. Finally, defective or returned products are efficiently processed, with options for repair, refurbishment, or disposal, ensuring a closed-loop supply chain.

Throughout this process, real-time data sharing and centralized information systems play a crucial role in enabling seamless coordination and decision-making. By leveraging technologies such as Enterprise Resource Planning (ERP) systems, Supply Chain Management (SCM) software, and advanced analytics, companies can gain end-to-end visibility, track inventory levels, monitor shipments, and make data-driven decisions to optimize operations.

Horizontal vs Vertical Supply Chain Integration

Supply chain integration can be achieved through two main strategies: horizontal integration and vertical integration. Understanding the distinctions between these approaches is important for companies to determine the most suitable strategy based on their specific goals and requirements. Horizontal integration refers to the collaboration and coordination among companies operating at the same level of the supply chain. This could involve partnerships between manufacturers, distributors, or retailers. The primary goal of horizontal integration is to leverage economies of scale, share resources, and optimize processes across multiple organizations within the same industry or market segment. Vertical integration, on the other hand, involves the consolidation or close coordination of various stages of the supply chain within a single organization or a closely linked network of companies. This can include upstream integration (controlling the sourcing and production of raw materials or components) or downstream integration (controlling the distribution and retail channels).

The benefits and challenges of each type of integration vary. Bargaining power with suppliers and customers is increased and cost savings are possible due to shared resources and infrastructure. The market reach and customer access are enhanced. Additionally, there is a pooling of expertise and knowledge sharing amongst colleagues. Shared resources and infrastructure also lead to cost savings. A number of challenges also arise, however. One of these is that potential conflicts of interest between partners may exist. The companies may also experience difficulty in aligning corporate cultures and decision-making processes. Further, there may be regulatory concerns related to anti-trust laws or market dominance.

Now let us compare this with the benefits and challenges of vertical integration. The benefits involved with vertical integration include greater control over the entire supply chain process and improved coordination and information flow. There is a reduced reliance on external suppliers or distributors and potential cost savings through streamlined operations. Amongst the challenges is the requirement for high capital investment. There is also an increased risk exposure and liability across the supply chain and the potential for inefficiencies or bottlenecks in certain stages. Another challenge is the limited flexibility and responsiveness to market changes that may arise.

Companies should carefully evaluate their strategic objectives, industry dynamics, and competitive landscape to determine whether horizontal or vertical integration or a combination of both, is the most suitable approach. For example, a company in a highly competitive market might benefit from horizontal partnerships to gain economies of scale, while a company seeking tighter control over quality and delivery times might pursue vertical integration.

Learn how Intuendi AI can streamline S&OP in this case study.

The Benefits of Supply Chain Integration

Integrating a supply chain offers numerous benefits that can significantly enhance a company’s operational efficiency, customer satisfaction, and profitability. This section will explore the key advantages of supply chain integration, including improved operational efficiency, enhanced customer satisfaction, reduced costs, and increased profitability.

Improving Operational Efficiency

One of the primary benefits of supply chain integration is the ability to streamline operations and eliminate redundancies across the various components of the supply chain. By fostering seamless communication and coordination among stakeholders, companies can optimize processes, reduce lead times, and minimize waste.

The integration enables techniques such as just-in-time (JIT) inventory management, where raw materials and components are delivered precisely when they are needed for production, reducing the need for excessive inventory holding and associated costs. Lean manufacturing principles, which focus on eliminating non-value-adding activities and continuous improvement, can be more effectively implemented in an integrated supply chain environment.

Automation and advanced technologies also play a crucial role in enhancing operational efficiency within an integrated supply chain.

Automated systems for order processing, inventory management, and logistics can minimize human errors, reduce processing times, and improve accuracy. Additionally, real-time data sharing and visibility across the supply chain enable proactive decision-making and rapid response to changes or disruptions.

It is interesting to note that Toyota’s renowned just-in-time and lean manufacturing practices, enabled by a highly integrated supply chain, have been credited with significant reductions in inventory costs, lead times, and defect rates.

Enhancing Customer Satisfaction

Customer satisfaction is a critical factor for success in today’s competitive marketplace, and supply chain integration plays a vital role in delivering superior customer experiences. By enabling real-time visibility, faster response times, and better product availability, integrated supply chains can significantly improve delivery times and meet customers’ ever-increasing expectations for speed and convenience. Integration also facilitates the incorporation of customer feedback and preferences into the supply chain processes. By collecting and analyzing customer data, companies can gain valuable insights into demand patterns, product preferences, and areas for improvement. This information can be used to refine production plans, optimize inventory levels, and tailor products and services to better meet customer needs. Amazon is an example of a company that can boast enhanced customer satisfaction through supply chain integration. Their highly integrated and efficient supply chain has enabled the company to offer fast and reliable delivery options, contributing to its reputation for exceptional customer service.

Reducing Costs and Increasing Profitability

While supply chain integration may require initial investments in technology, infrastructure, and process optimization, the long-term benefits can significantly reduce overall costs and increase profitability for companies. By eliminating redundancies, minimizing waste, and optimizing resource utilization, integrated supply chains can lead to substantial cost savings. One key area of cost reduction is inventory management. Integration enables better demand forecasting and real-time inventory visibility, allowing companies to maintain optimal inventory levels and reduce the costs associated with excess or obsolete stock. Just-in-time production and lean practices further minimize inventory carrying costs and ensure efficient use of resources.

Supply chain integration also facilitates better utilization of transportation and logistics resources, reducing the costs associated with inefficient routing, empty backhauls, and underutilized capacity. Collaborative transportation management and load optimization can lead to significant cost savings in this area. Furthermore, by enabling faster response times and better product availability, integrated supply chains can help companies capture more market share and increase revenue streams. Improved customer satisfaction and loyalty can also contribute to long-term profitability. Walmart serves as an example to showcase the cost savings and increased profitability achieved by successfully implementing integrated supply chains. Their highly integrated supply chain has been credited with enabling the company to offer lower prices to consumers while maintaining profitability through cost efficiencies.

Learn how one company managed to increase its ROI on inventory whilst increasing its profitability through Intuendi’s accurate AI-driven demand planning in this case study.

Challenges and Barriers to Integration

While the benefits of supply chain integration are compelling, implementing and maintaining an integrated system can present various challenges and barriers. This section will explore the technical, organizational, and global challenges companies may face when pursuing supply chain integration, as well as strategies to overcome these obstacles.

Technical Challenges in Integration

Integrating multiple systems, processes, and stakeholders across a supply chain can present significant technical challenges. We will delve into some of the common technical issues that may arise. System compatibility and interoperability may present a challenge. Different stakeholders may use different software, hardware, and data formats, making it difficult to seamlessly exchange information and integrate processes. Ensuring compatibility and establishing common standards can be a complex and costly endeavor. Data integration and management is yet another challenge. Consolidating and harmonizing data from disparate sources, ensuring data quality, and enabling real-time data sharing across the supply chain can be challenging, particularly for companies with legacy systems or siloed data repositories.

Cybersecurity concerns are an additional challenge that arises. As supply chains become more interconnected and reliant on digital technologies, the risk of cyber threats, such as data breaches, malware attacks, and system vulnerabilities, increases. Robust cybersecurity measures and protocols must be implemented to protect sensitive data and ensure the integrity of the integrated systems. To overcome these technical challenges, companies must be willing to invest in the right technology and infrastructure. This may include adopting modern cloud-based platforms, implementing standardized data exchange protocols, and implementing robust cybersecurity measures. Additionally, partnering with experienced technology providers and consulting firms can provide valuable expertise and guidance throughout the integration process.

Strategies such as phased implementation, pilot projects, and comprehensive testing can help mitigate risks and ensure a smooth transition to an integrated supply chain system. Providing adequate training and support for all stakeholders involved is also crucial for the successful adoption and utilization of the integrated systems.

Organizational and Cultural Barriers

Beyond technical challenges, companies may also face organizational and cultural barriers when attempting to integrate their supply chains. These barriers can include many different factors. Implementing an integrated supply chain often requires significant changes to established processes, roles, and responsibilities. Employees and stakeholders may resist these changes due to fear of job insecurity, loss of control, or simple inertia.

Supply chain integration also requires a diverse set of skills, including data analytics, project management, and cross-functional collaboration. Companies may struggle to find or develop the necessary talent to support the integration efforts. Traditional organizational structures with siloed departments and a lack of cross-functional communication can hinder the seamless integration of supply chain processes. Breaking down these silos and fostering a collaborative culture is essential for successful integration.

Effective change management strategies are crucial for overcoming these organizational and cultural barriers. This may involve clear communication of the benefits and rationale for integration, providing adequate training and support, involving stakeholders in the decision-making process, and addressing concerns and resistance proactively.

Additionally, fostering a culture of collaboration, continuous improvement, and shared goals is essential. Companies may need to restructure their organizations, establish cross-functional teams, and implement incentives and performance metrics that encourage integration and collaboration across the supply chain.

Global Supply Chain Risks and Compliance Issues

For companies with global supply chain operations, additional challenges arise in the form of regulatory compliance, geopolitical risks, and the complexities of managing a distributed network of stakeholders across multiple countries and regions. Regulatory compliance is a significant concern, as companies must adhere to various laws, standards, and regulations related to trade, customs, labor practices, environmental protection, and data privacy across multiple jurisdictions. Failure to comply can result in fines, penalties, and reputational damage. Geopolitical risks, such as trade disputes, political instability, and currency fluctuations, can disrupt the flow of goods, materials, and information within an integrated supply chain. These risks require contingency planning, risk mitigation strategies, and the ability to rapidly adapt to changing conditions. Managing a global supply chain also involves dealing with cultural differences, language barriers, and varying business practices across regions. Effective communication, cultural awareness, and locally tailored strategies are essential for successful integration and coordination among global stakeholders.

To address these challenges, companies must implement robust risk management processes, including scenario planning, diversification of suppliers and transportation routes, and contingency plans for supply chain disruptions. Investing in technologies that enable end-to-end visibility, real-time monitoring, and rapid decision-making can also help mitigate global supply chain risks. Additionally, companies should stay informed about regulatory changes, engage with local experts and consultants, and foster strong relationships with government agencies and industry associations to ensure compliance and navigate the complexities of operating in multiple jurisdictions.

Technological Innovations Shaping Integrated Supply Chains

The rapid pace of technological innovation is transforming the landscape of supply chain management, enabling greater integration, efficiency, and visibility. This section will explore some of the key technologies driving the evolution of integrated supply chains, including the Internet of Things (IoT), Artificial Intelligence (AI), blockchain technology, and advanced analytics and big data.

The Impact of IoT and AI on Supply Chains

The Internet of Things (IoT) has revolutionized supply chain operations by enabling real-time tracking and monitoring of assets, inventory, and shipments. IoT devices, such as RFID tags, sensors, and GPS trackers, can provide granular data on the location, condition, and status of goods as they move through the supply chain.

This real-time visibility enables proactive decision-making, optimized routing, and rapid response to potential disruptions or delays. For example, if a shipment is delayed due to unforeseen circumstances, alternative routes or transportation modes can be swiftly identified and implemented, minimizing the impact on delivery times and customer satisfaction. Artificial Intelligence (AI) and machine learning are also playing a crucial role in enhancing supply chain integration and efficiency. AI algorithms can analyze vast amounts of data from various sources, such as customer orders, inventory levels, weather patterns, and transportation networks, to provide accurate demand forecasting and predictive analytics.

These insights can be used to optimize production planning, inventory management, and resource allocation, reducing waste and improving overall efficiency. AI can also enable automated decision-making and execution of supply chain processes, such as order fulfillment, routing optimization, and predictive maintenance of equipment and infrastructure. Serving as an example of the effectiveness of implementing loT and AI is Amazon and DHL. They have leveraged IoT and AI to streamline their logistics and delivery processes, resulting in significant cost savings and improved customer experiences.

Blockchain Technology and Transparency

Blockchain technology, best known for its application in cryptocurrencies, is also gaining traction in supply chain management due to its ability to enhance transparency, traceability, and security. A blockchain is a decentralized, immutable ledger that records transactions across a network of participants, ensuring data integrity and preventing tampering. In the context of supply chains, blockchain can be used to create a transparent and auditable record of the movement of goods, from raw material sourcing to final delivery. Each step in the supply chain can be recorded on the blockchain, providing real-time visibility and traceability for all stakeholders involved. This level of transparency can be particularly valuable in industries with complex supply chains, such as food and pharmaceuticals, where product provenance, quality, and safety are critical concerns. Product shelf life is also a concern. Blockchain can help track the origin of ingredients, monitor temperature and handling conditions, and quickly identify and isolate any contaminated or counterfeit products. Additionally, smart contracts, which are self-executing agreements encoded on the blockchain, can automate and streamline processes such as payments, shipment verifications, and compliance checks, reducing the need for manual interventions and increasing efficiency.

Companies across various industries, including retail, logistics, and manufacturing, are exploring the potential of blockchain technology in their supply chains.

Advanced Analytics and Big Data

The integration of supply chains generates vast amounts of data from various sources, such as IoT devices, enterprise systems, and customer interactions. Advanced analytics and big data techniques are essential for extracting valuable insights from this data, enabling data-driven decision-making and continuous improvement. Predictive analytics can be used to forecast demand patterns, identify potential supply chain disruptions, and optimize inventory levels and resource allocation. Prescriptive analytics can provide recommendations for optimal courses of action based on multiple variables and constraints. Furthermore, machine learning algorithms can analyze historical data and identify patterns and trends that may not be apparent to human analysts, enabling more accurate forecasting and proactive decision-making. Big data technologies, such as distributed computing frameworks and data lakes, are crucial for storing, processing, and analyzing large volumes of structured and unstructured data generated within integrated supply chains. Companies can leverage these advanced analytics and big data capabilities to gain deeper insights into supply chain performance, identify areas for improvement, and make informed decisions that drive operational efficiency, cost savings, and enhanced customer experiences. A number of companies have utilized advanced analytics and big data to improve various aspects of their supply chain operations, such as demand forecasting, inventory optimization, route planning, and predictive maintenance.

How to Integrate Your Supply Chain

After exploring the benefits, challenges, and technological advancements shaping integrated supply chains, it is essential to understand the practical steps and strategies for successfully integrating your own supply chain. This section will provide a comprehensive guide, including strategic planning, stakeholder engagement, best practices, and recommended tools and software. Additionally, it will discuss key performance indicators (KPIs) and metrics for measuring the success of your integration efforts.

Strategies for Effective Integration

Integrating a supply chain is a complex and multi-faceted undertaking that requires careful planning, execution, and continuous improvement. Here is a step-by-step guide to help organizations embark on this journey.

To start off they should conduct a comprehensive assessment. This can be done by evaluating the current supply chain processes and identifying inefficiencies, bottlenecks, and areas for improvement. The existing technology infrastructure, data management practices, and organizational structures should also be carefully analyzed. This should be followed by defining clear objectives and goals. Specific, measurable, achievable, relevant, and time-bound (SMART) goals should be established for your supply chain integration efforts. These goals should align with your overall business objectives and address the identified areas for improvement.

Next is the development of a strategic roadmap. A detailed roadmap must be created that outlines the phases of integration, timelines, resource requirements, and key milestones. This roadmap should be flexible and adaptable to accommodate changes or unforeseen challenges. Stakeholders must be engaged and cross-functional teams must be built. Supply chain integration requires collaboration and buy-in from all stakeholders, including suppliers, manufacturers, distributors, and customers. Establish cross-functional teams that include representatives from various departments and functions to ensure a holistic approach. Investing in technology and infrastructure is an essential component. In order to support supply chain integration, companies should evaluate and invest in the necessary technologies and infrastructure. This may include enterprise resource planning (ERP) systems, supply chain management (SCM) software, data integration tools, and communication platforms. It is essential to establish common standards, processes, and protocols for data exchange, communication, and collaboration across the supply chain. This will facilitate seamless integration and ensure consistency.

Ensure that all stakeholders receive adequate training and support to effectively utilize the new processes, technologies, and systems. Continuous learning and knowledge sharing should be encouraged. Continuously monitor the performance of your integrated supply chain using defined KPIs and metrics. Identify areas for improvement and implement optimization strategies based on data-driven insights. Encourage a culture of continuous improvement, where all stakeholders are empowered to identify and address inefficiencies, suggest innovations, and contribute to the ongoing enhancement of the integrated supply chain. Throughout this process, it is crucial to maintain open communication, address concerns and resistance proactively, and celebrate milestones and successes to sustain momentum and engagement.

Tools and Software Recommendations

To facilitate supply chain integration, organizations can leverage a range of tools and software solutions designed specifically for this purpose. When selecting the appropriate tools and software, organizations should consider factors such as scalability, integration capabilities, user-friendliness, and vendor support. It is also essential to ensure that the chosen solutions align with the organization’s specific requirements and can seamlessly integrate with existing systems and infrastructure. Here are some recommended tools and their features:

To facilitate supply chain integration, organizations can leverage a range of tools and software solutions designed specifically for this purpose. When selecting the appropriate tools and software, organizations should consider factors such as scalability, integration capabilities, user-friendliness, and vendor support. It is also essential to ensure that the chosen solutions align with the organization’s specific requirements and can seamlessly integrate with existing systems and infrastructure. Here are some recommended tools and their features:

Enterprise Resource Planning (ERP) systems such as SAP, Oracle, and Microsoft Dynamics, provide a centralized platform for managing and integrating various business processes, including procurement, production, inventory management, and financials. These systems enable real-time data sharing and visibility across the supply chain.

Dedicated Supply Chain Management (SCM) software solutions, such as Manhattan Associates, JDA Software, Intuendi, and Kinaxis, offer advanced features for supply chain planning, optimization, and execution. These tools include capabilities for demand forecasting, inventory optimization, transportation management, and supplier collaboration.

Data integration and ETL (Extract, Transform, Load) tools like Informatica, Talend, and AWS Glue facilitate the integration of data from disparate sources, ensuring data quality, and enabling seamless data exchange across the supply chain.

Cloud-based platforms like Microsoft Teams, Slack, and Asana enable real-time communication, file sharing, and task management among supply chain stakeholders, fostering collaboration and coordination.

Advanced analytics and business intelligence (BI) tools like Tableau, Power BI, and Qlik Sense allow organizations to visualize and analyze supply chain data, uncover insights, and make data-driven decisions.

For organizations interested in leveraging blockchain technology, platforms like Hyperledger Fabric, Ethereum, and IBM Blockchain provide a secure and transparent way to track and record supply chain transactions, enabling end-to-end traceability and provenance.

Internet of Things (IoT) platforms such as Microsoft Azure IoT Suite, AWS IoT Core, and Google Cloud IoT, enable the integration of IoT devices (sensors, RFID tags, GPS trackers) into the supply chain, facilitating real-time monitoring and tracking of assets, inventory, and shipments.

Measuring Success: KPIs and Metrics

To ensure the successful implementation and ongoing optimization of an integrated supply chain, it is crucial to measure and track key performance indicators (KPIs) and metrics. These metrics provide quantifiable measures of performance, enabling organizations to set benchmarks, monitor progress, and identify areas for improvement.

Let us discuss some commonly used KPIs and metrics in supply chain integration:

The on-time delivery rate is a metric that measures the percentage of orders or shipments delivered to customers within the promised or expected delivery timeframe, reflecting the efficiency and reliability of the supply chain.

The inventory turnover rate metric measures the number of times inventory is sold or used over a given period, indicating the efficiency of inventory management practices and helping to identify potential overstocking or understocking issues.

The cash-to-cash cycle time metric measures the time it takes for a company to convert its investments in inventory into cash from sales, reflecting the overall efficiency and speed of the supply chain.

The perfect order rate metric measures the percentage of orders that are delivered complete, on time, and without errors or damage, providing a comprehensive view of supply chain performance.

Supply chain costs include metrics such as total logistics costs, inventory carrying costs, and transportation costs, enabling organizations to identify opportunities for cost savings and optimization.

Metrics such as customer satisfaction scores, Net Promoter Score (NPS), and customer retention rates can help organizations assess the impact of supply chain integration on customer experiences and loyalty.

Metrics like supplier on-time delivery rate, quality ratings, and responsiveness can help evaluate the performance of suppliers and identify areas for improvement or potential supplier changes.

Organizations should establish clear targets and benchmarks for these KPIs and metrics, aligning them with their specific goals and industry standards. Regular monitoring and reporting of these metrics, combined with data-driven analysis, can provide valuable insights into supply chain performance and enable informed decision-making for continuous improvement.

Final Recommendations and Future Perspectives

In conclusion, supply chain integration has become a critical strategy for organizations seeking to enhance operational efficiency, customer satisfaction, and profitability in today’s highly competitive and dynamic business environment. By aligning and coordinating the various components and processes involved in the creation and distribution of products or services, companies can leverage real-time visibility, collaboration, and data-driven decision-making to optimize their operations and gain a competitive advantage. Throughout this comprehensive guide, we have explored the key aspects of supply chain integration, including understanding the concept and evolution of integrated supply chains, identifying the primary goals and objectives of integration, examining the key components and stakeholders involved, outlining the process and strategies for horizontal and vertical integration, highlighting the benefits of improved efficiency, customer satisfaction, and cost savings, addressing the technical, organizational, and global challenges and barriers to integration, exploring the impact of emerging technologies like IoT, AI, blockchain, and advanced analytics, providing a step-by-step guide for integrating your supply chain and finally recommending tools, software, and KPIs for measuring success.

Based on the insights and strategies discussed, here are some final recommendations for companies looking to integrate their supply chains:

Develop a clear vision and strategic roadmap aligned with your business objectives. Foster a culture of collaboration, data-driven decision-making, and continuous improvement. Invest in modern technologies and infrastructure to enable seamless integration and real-time visibility engage stakeholders across the supply chain and build cross-functional teams. Prioritize change management and provide adequate training and support. Additionally, implement robust risk management processes and contingency plans. Continuously monitor and optimize performance using defined KPIs and metrics. And lastly, stay informed about emerging technologies and industry trends.

Looking toward the future, supply chain integration will continue to evolve and be shaped by technological advancements, shifting consumer demands, and global market dynamics. There are, however, potential trends and technologies that could impact supply chain integration. Let us list some of these:

Increased adoption of artificial intelligence and machine learning for predictive analytics, automated decision-making, and optimization; widespread implementation of blockchain technology for enhanced transparency, traceability, and security across global supply chains; integration of advanced robotics and autonomous systems in warehousing, transportation, and last-mile delivery; proliferation of the Internet of Things (IoT) and sensor technologies for real-time monitoring and tracking of assets and shipments; adoption of sustainable and environmentally-friendly practices throughout the supply chain, driven by regulatory requirements and consumer preferences; greater emphasis on supply chain resilience and agility to adapt to disruptions and changing market conditions and increased collaboration and strategic partnerships among supply chain stakeholders, including competitors, to leverage shared resources and expertise.

As these trends continue to unfold, companies that embrace supply chain integration and leverage emerging technologies will be well-positioned to stay competitive, reduce costs, and deliver superior customer experiences. The future of supply chain management lies in seamless integration, data-driven decision-making, and the ability to adapt and innovate continuously.

Learn how Intuendi AI can help you create a more robust supply chain.