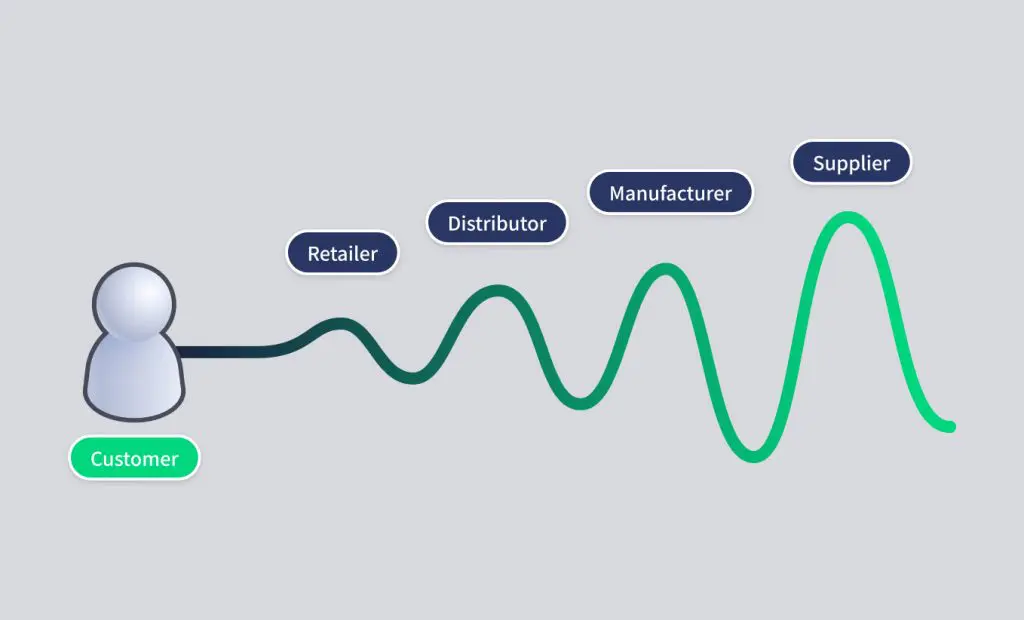

A single storm on the other side of the world can empty a store shelf in your local town. The modern supply chain is a sprawling, interconnected web, both incredibly resilient and shockingly fragile. It operates under constant pressure from global disruptions, ever-increasing customer expectations for speed, and a tidal wave of data from countless sources. In this complex environment, trying to manage operations with spreadsheets and intuition is like navigating a hurricane with a paper map. Artificial Intelligence is not just another piece of software; it is the strategic compass that transforms these immense challenges into powerful opportunities for efficiency, resilience, and sustainable growth. It marks the critical shift from a supply chain that simply reacts to one that intelligently anticipates the future.

What Is AI in the Supply Chain and Why Is It Essential?

At its core, AI in the supply chain is the use of intelligent computer systems to augment, automate, and fundamentally enhance traditional logistics and management processes. Its purpose is to do what the human mind cannot: sift through massive, complex datasets to identify hidden patterns, predict future outcomes with stunning accuracy, and in some cases, make autonomous decisions to optimize operations in real time.

This capability has become absolutely essential in the era of Supply Chain 4.0. We are inundated with information from sensors, devices, and global markets. Without a powerful engine to process it, this data is just noise. AI is that engine. It turns raw information into actionable intelligence, enabling companies to finally move away from a reactive posture, where they are constantly fighting fires, and into a proactive and predictive model where they can see challenges coming and act before they become crises.

The Strategic Advantages of AI in Supply Chain Management

Integrating AI into supply chain operations unlocks a cascade of strategic benefits that ripple through the entire organization. One of the most immediate impacts is a significant reduction in operational costs. By automating repetitive tasks, optimizing resource allocation, and minimizing waste through better forecasting, companies can free up capital and human resources for more strategic initiatives.

This leads directly to vastly improved efficiency. AI algorithms can optimize nearly every process, from how goods are stored in a warehouse to the exact route a delivery truck takes. Beyond speed, AI delivers unprecedented end-to-end visibility. It allows managers to track materials and products in real time across the entire chain, offering a clear, granular view that was previously impossible to achieve. This new clarity supports a fundamental shift toward truly data-driven decision-making, where choices are based on predictive models and real-time analytics rather than historical averages or guesswork. The result is a more agile, responsive operation that can also improve its sustainability by reducing its carbon footprint and manage risk with far greater foresight. This proactive stance is the cornerstone of modern supply chain risk management.

Key Applications of AI in the Supply Chain

The true value of artificial intelligence is most clearly understood not as an abstract concept, but through its practical applications that are already reshaping key functions of the supply chain. These are not futuristic ideas; they are tangible solutions delivering measurable results today. The following examples explore specific use cases where AI is making a tangible impact on performance and profitability.

Demand Forecasting and Inventory Optimization

One of the most powerful applications of AI is its ability to create hyper-accurate demand forecasts. By leveraging machine learning, systems can analyze not just historical sales data but also market trends, seasonality, competitor pricing, and even unstructured external factors like social media sentiment or weather patterns. This granular, predictive insight connects directly to intelligent Inventory Management. With a clear picture of future demand, companies can avoid both costly stockouts that lead to lost sales and wasteful overstock situations that tie up capital and warehouse space. developing strategies on how to prevent stock outs becomes a direct benefit of improved forecasting accuracy. The system ensures the right amount of product is always in the right place at the right time.

Tools like Intuendi apply these advanced forecasting methods automatically, helping teams reduce stockouts and avoid excess inventory.

Warehouse Automation and Robotics

The modern warehouse is rapidly becoming a “smart warehouse,” orchestrated by AI. This technology is the brain behind fleets of autonomous mobile robots (AMRs) that navigate aisles to pick and sort orders with incredible speed and precision. It powers automated storage and retrieval systems (AS/RS) that maximize vertical space and manage inventory flow. Furthermore, computer vision systems equipped with AI can perform quality control inspections or conduct inventory checks in seconds, identifying defects or discrepancies far faster and more reliably than the human eye. This level of automation not only boosts throughput but also significantly reduces human error and improves workplace safety.

Transportation and Route Optimization

AI is revolutionizing logistics by making transportation networks smarter and more efficient. Advanced algorithms analyze countless variables in real time, including traffic patterns, weather conditions, vehicle capacity, and specific delivery windows, to calculate the most efficient delivery routes. This dynamic optimization leads directly to reduced fuel costs, faster delivery times, and a smaller carbon footprint. The intelligence extends beyond the road to include yard automation, streamlining the movement of trailers and containers, and optimizing global freight management by identifying the most cost-effective shipping lanes and carriers.

Predictive Procurement and Supplier Management

In procurement, AI acts as a strategic advisor. It can predict future material needs based on production forecasts, automate routine purchasing processes, and provide data-driven recommendations for supplier selection. AI systems continuously analyze supplier performance metrics, flagging potential risks before they escalate. They can even manage initial negotiations through intelligent chatbots. Crucially, these systems can scan global financial and geopolitical data to identify potential disruptions in the supply network, allowing procurement teams to proactively find alternative sources and mitigate risk before it impacts production.

The Role of Generative AI in Transforming the Supply Chain

While traditional AI excels at analyzing existing data, Generative AI (GenAI) represents a paradigm shift because of its ability to create entirely new content and solutions. In a supply chain context, this unlocks new frontiers of optimization. Instead of just analyzing past performance, GenAI can generate multiple optimized production plans based on a set of constraints, allowing planners to choose the best possible scenario. It can take complex logistics data and automatically create simplified, natural-language reports for executives. It can even automate sophisticated communication with suppliers, drafting emails, negotiating terms, and summarizing outcomes, freeing up human teams to focus on strategic relationships.

Enabling Technologies Behind Supply Chain AI

Artificial intelligence is an umbrella term, a powerful capability built upon several interlocking technologies working in concert. Understanding these core components helps clarify how AI achieves its transformative results.

Machine Learning and Deep Learning

Machine Learning (ML) is the engine of modern AI. It is the technology that enables systems to learn from data, identify patterns, and make decisions without being explicitly programmed for every scenario. It is the foundation for demand forecasting, predictive maintenance on machinery, and customer segmentation. Deep Learning, a more advanced subset of ML, uses complex neural networks to recognize intricate patterns in massive datasets. It is the technology that powers more sophisticated applications like computer vision and natural language processing.

IoT, Big Data, and Advanced Analytics

These three elements form a powerful, symbiotic loop. The Internet of Things (IoT) refers to the vast network of sensors embedded in vehicles, containers, machinery, and infrastructure. These sensors collect enormous volumes of real-time data, often referred to as Big Data. By itself, this data is overwhelming. But when fed into AI-powered advanced analytics platforms, it becomes the fuel for insight. This is how a company can get a live feed of its entire supply chain and use that information to make immediate, intelligent adjustments.

Computer Vision and Natural Language Processing (NLP)

Two of AI’s most human-like capabilities are seeing and understanding language. Computer Vision gives machines the ability to interpret and understand visual information from the real world. This is used on production lines to spot microscopic defects, in warehouses to identify damaged packages, or at ports to read container numbers automatically. Natural Language Processing (NLP) grants AI the ability to understand, interpret, and generate human language. It is used to automate the processing of unstructured documents like invoices and bills of lading or to power intelligent chatbots that provide instant customer service and support.

Challenges and Risks of Adopting AI

Despite its immense potential, the path to AI adoption is not without its obstacles. The single most critical dependency is high-quality data; an AI system trained on inaccurate or incomplete information will produce flawed results. Many companies also face the technical challenge of integrating new AI platforms with their existing legacy systems, such as enterprise resource planning (ERP) software.

The financial investment can also be significant, requiring a clear business case to prove return on investment. Operationally, there are risks to consider, such as an overreliance on automated systems, cybersecurity vulnerabilities, and the need to protect sensitive supply chain data. Perhaps the most significant challenge is the human one: bridging the skills gap by training the existing workforce to collaborate effectively with these new intelligent systems, transforming their roles from manual operators to strategic overseers.

How to Implement a Successful AI Strategy

Embarking on an AI transformation requires a clear and deliberate plan, not a blind leap of faith. The first step is a frank assessment of your company’s digital maturity. You must take stock of your existing data infrastructure, networks, and internal capabilities to understand your starting point. From there, the key is to create a strategic roadmap. Instead of trying to solve everything at once, identify one or two specific, high-impact problems and define clear Key Performance Indicators (KPIs) to measure success.

This focused approach builds momentum and demonstrates value early on. With a clear goal in mind, you can begin the process of selecting the right technology partners and solutions that fit your unique needs. This entire process should be viewed not as a one-time project but as an ongoing journey. A successful strategy requires continuous monitoring, iterative improvements, and a commitment to employee training and adaptation to ensure the technology delivers on its promise for years to come.