From the coffee beans grown on a distant mountain to the smartphone assembled across continents, the journey of a product to your hands is a marvel of global coordination. This intricate web of suppliers, manufacturers, shippers, and retailers is the supply chain, the silent engine of modern commerce. But in a world where speed and cost define success, simply having a functional supply chain is not enough. True competitive advantage comes from making it exceptionally efficient. This efficiency is far more than a cost-cutting exercise; it is the strategic core that dictates customer satisfaction, boosts profitability, and ensures long-term business sustainability.

What is Supply Chain Efficiency?

Let’s break it down. A supply chain is the entire journey a product takes, from raw materials to the customer’s hands—the network of people, companies, and resources that make it happen. So, supply chain efficiency is all about optimizing every resource in that network—time, money, materials, and people—to deliver goods with the least possible waste and the greatest possible value. This goes way beyond simple cost-cutting. Sure, saving money is a nice side effect, but the real goal is to make your entire operation sharper, faster, and more reliable.

Think about a coffee company. Its supply chain starts with farmers growing the beans. Efficiency there might mean negotiating smarter contracts or finding growers closer to home. The next link is roasting and packaging, where you can gain an edge with fine-tuned production schedules and automated lines. Finally, you have to get that coffee to cafes and stores, and that’s where route-planning software can slash fuel costs and delivery times. At every single stage, it’s about making the process leaner and more intelligent.

Efficiency vs. Effectiveness vs. Responsiveness

You’ll hear these three words thrown around a lot, often as if they mean the same thing. They don’t. Nailing the difference is the key to building a supply chain that actually performs.

Efficiency is about doing things right. It’s an internal focus on using your resources wisely. An efficient supply chain runs at the lowest possible cost, trimming the fat from transport, inventory, and labor. It’s a measure of how well you turn your inputs into outputs.

Effectiveness is about doing the right things. This is all about the outside world—meeting customer demand. An effective supply chain delivers what people want, when they want it, and where they want it. After all, what’s the point of efficiently mass-producing a product nobody buys? That’s not just ineffective; it’s a waste of perfectly good efficiency.

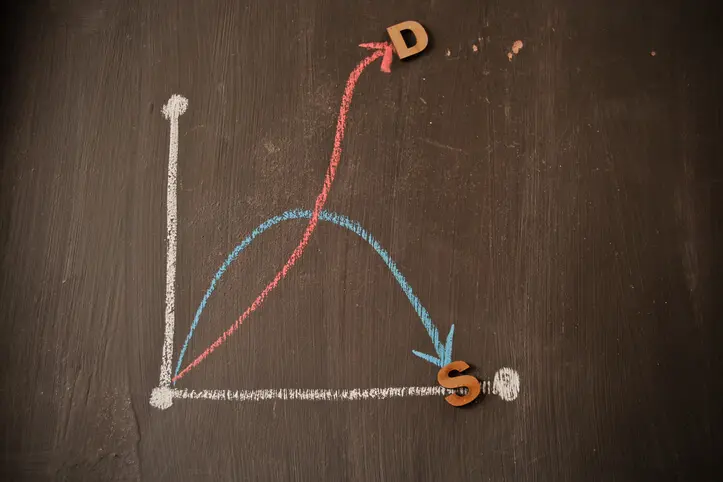

Responsiveness is about speed and agility. It’s your supply chain’s ability to pivot when things go sideways—a sudden spike in demand, a supplier shutting down, a port strike. A responsive company can adapt on the fly. Being able to air-freight a product to meet unexpected demand is incredibly responsive, but if it costs a fortune, it’s also wildly inefficient.

The real magic happens when you stop chasing one at the expense of the others. A truly modern supply chain is efficient enough for the day-to-day, effective enough to keep customers happy, and responsive enough to handle whatever the world throws at it.

Why Improving Supply Chain Efficiency is Crucial

The payoff for getting this right is huge, impacting your finances, your market position, and even how people see your brand.

First up: a direct hit to your bottom line by reducing operational costs. When you optimize everything from sourcing materials to warehousing and shipping, you slash expenses. That cash can either beef up your profit margins or be passed along to customers, giving you a serious edge on price.

Second, it builds a massive competitive advantage. A well-oiled supply chain means faster delivery, fewer stockouts, and almost no order mistakes. That kind of reliability is exactly what builds an amazing customer experience. In a world where we all want things now, that dependability creates fierce customer satisfaction and loyalty.

And finally, there’s a benefit that’s becoming less of a bonus and more of a requirement: efficiency is green. The whole philosophy of eliminating waste—from optimizing truck routes to managing resources better—naturally leads to using less energy, cutting emissions, and shrinking your environmental footprint. In an age where customers and investors are watching closely, a sustainable supply chain is no longer optional.

Key Metrics to Measure Supply Chain Efficiency

You can’t fix what you can’t see. Key Performance Indicators (KPIs) are the dashboard for your supply chain, letting you spot problems, measure progress, and see if your big ideas are actually working.

Financial Metrics

This is where operations talk money. One of the most powerful metrics is Cost-to-Serve, which adds up every single penny it takes to get an order to a customer, from the warehouse shelf to their front door. It’s a brilliant way to see which customers or products are actually making you money. Other essentials include tracking transportation and warehousing costs as a percentage of your revenue, giving you a clear picture of your biggest logistical expenses.

Inventory Metrics

Managing inventory is a high-wire act, and these metrics tell you how you’re doing. The Inventory Turnover Ratio reveals how many times you sell and replace your stock in a given period. A high number is great; it means products are flying off the shelves. On the flip side, Days of Supply tells you how many days you could survive if your suppliers vanished tomorrow. You want this number low, but not too low—that’s when you risk stockouts. Too high, and you have cash just sitting on a shelf collecting dust.

Order and Fulfillment Metrics

These KPIs look at your supply chain through your customer’s eyes. The Perfect Order Index is the ultimate report card, measuring the percentage of orders that go off without a single hitch—right product, right place, right time, right condition, right paperwork. Nothing missed. Simpler, but just as vital, are the On-Time Delivery Rate (your reliability score) and the Order Fulfillment Cycle Time (the total speed of your operation, from click to doorbell).

Core Strategies to Enhance Supply Chain Efficiency

Tech is a huge piece of the puzzle, but it’s not the whole picture. Real efficiency is built on smart processes, strong relationships, and a culture that’s always looking for a better way.

Strengthen Supplier and Partner Relationships

The days of treating suppliers like interchangeable vendors are over. Today, it’s all about building strategic, long-term partnerships. This kind of collaboration creates transparency, which leads to better planning, shared risks, and a supply chain that’s stronger from end to end. You can make this happen by setting up a clear vendor management program to track performance, keeping communication lines wide open, and creating deals that reward everyone for being reliable and innovative.

Optimize Inventory and Warehouse Management

Your inventory is where efficiency either thrives or dies. It all starts with sharp demand forecasting, using past data and market intel to predict what customers will want, so you don’t get stuck with a warehouse full of things nobody is buying. From there, inventory models like Just-in-Time (JIT) can radically reduce how much stock you have to hold. Inside the warehouse itself, a smart layout paired with a modern Warehouse Management System (WMS) can shave critical minutes off the time it takes to pick, pack, and ship. And don’t forget reverse logistics—a smooth system for handling returns is non-negotiable, or it’ll quickly become a black hole for your resources.

Implement Lean Principles and Continuous Improvement

The “Lean” philosophy is brilliantly simple: hunt down and eliminate waste in all its forms. That could be excess inventory, time spent waiting for a shipment, or a truck driving an unnecessary mile. To make it work, you have to bake a culture of continuous improvement right into your DNA. This means holding regular process reviews to find weak spots, empowering every employee to suggest fixes, and investing in training to build a team of supply chain experts. It’s a mindset where every process is an opportunity to get a little bit better.

Leveraging Technology for a Smarter Supply Chain

This is where technology changes the game, turning old-school supply chains into data-driven, intelligent, and even automated systems.

Automation and Robotics

Think of automation in two ways. First, there’s Robotic Process Automation (RPA), software that takes over tedious back-office work like processing invoices or generating shipping labels, freeing up your team to think strategically. Then there’s the physical stuff: automation and robotics in the warehouse. We’re talking about automated vehicles zipping around and robotic arms that can pick, pack, and sort goods with a speed and accuracy no human can match.

Data, Analytics, and AI

Data is the fuel that makes a modern supply chain run. Supply Chain Management (SCM) software pulls all your information into one place, creating a single source of truth for you and your partners. With Big Data and predictive analytics, you can spot hidden trends, forecast demand with startling accuracy, and optimize routes in real time. Then Artificial Intelligence (AI) and Machine Learning (ML) kick it up another notch, enabling dynamic, real-time decision-making and building systems that actually learn and adapt on their own.

Intuendi puts this into practice, helping companies forecast demand more accurately, optimize inventory, and build smarter, data-driven supply chains.

Visibility and Traceability Technologies

Knowing exactly where your shipment is at any given moment is no longer a nice-to-have; it’s a must. Internet of Things (IoT) sensors can provide live updates on a container’s location, temperature, and even if it’s been tampered with, giving you a god-like view of your entire network. For the ultimate level of trust and security, Blockchain technology provides a shared, unchangeable record of a product’s journey from source to consumer. It’s a game-changer for verifying authenticity and building total confidence in your supply chain.

Overcoming Common Challenges and Risks

Of course, making all this happen isn’t a walk in the park. Building supply chain resilience is critical for surviving shocks like natural disasters, geopolitical flare-ups, or a key supplier going under. That means not putting all your eggs in one basket and always having a Plan B. Internally, you have to manage the human side of things, like the inevitable resistance to new tech or processes. And finally, always remember that a supply chain is only as strong as its weakest link. Success depends on seamless collaboration and data sharing between every single partner, making sure information flows just as smoothly as your products.