The global supply chain landscape in 2025 is replete with challenges that have extensive implications for businesses and economies worldwide, these are known as supply chain issues. From increasing freight costs to cybersecurity threats and labor shortages, there are a plethora of factors to consider in configuring supply chains towards resilience. This article delineates and examines the rippling effect of key obstacles in supply chain management, including high freight prices, labor scarcity, cyber risks, consumer demands, port congestion, forecasting issues, material shortages, and the aftermath of the COVID-19 pandemic. We will observe the manner in which an acute understanding and thorough appraisal of these challenges can empower businesses towards efficient and resilient supply chain operations in the current economic and geopolitical environment. Proactive management and strategic adjustments are essential for businesses to navigate these complexities successfully.

Common Challenges in Supply Chain Management

In 2024, businesses remain susceptible to a complex and dynamic supply chain environment. With ongoing global market changes and lingering effects of the pandemic, companies are confronted with supply chain issues that can disrupt their operations and affect their bottom line. Here, we delve into the prevalent challenges in supply chain management currently being faced by businesses.

Increased freight prices

The surge in freight costs has had substantial financial implications on business and their supply chain due to a number of factors. Increasing freight costs have presented significant financial strains on businesses and their supply chains. Circumstances created by increasing fuel prices caused by the global energy crisis and geopolitical tensions have had a notable effect on the transportation sector while disruptions in trade agreements and regulations continue affecting established trade routes. Other transportation challenges include a shortage of skilled truck drivers reducing freight capacity and driving up prices. As such, the consequences of higher freight prices extend widely as these additional costs are ultimately transferred to consumers, leading to inflation and potentially reducing consumer demand.

Labor shortages

Supply chain operations are labor-intensive, Labor shortages in key sectors like transportation and warehousing raise a challenge for supply chain operations. This is due to occurrences such as demographic shifts, pandemic-related disruptions, and unfavorable working conditions. Shortages in this manner can cause supply chain issues such as delays, reduced productivity, and increased operational costs, which can obstruct supply chain efficiency and responsiveness.

Cybersecurity threats

As the digital landscape expands, supply chains face an increasing threat of cyberattacks. High-profile cyber incidents, involving ransomware and data leaks, have exposed vulnerabilities in supply chain networks. Cyber threats come in various forms, such as malware and ransomware, which can halt business operations and cause expensive recovery processes. Data breaches can lead to the loss of sensitive and valuable information, deeply impacting companies. Attacks on logistics, ports, and transport systems can also have a massive impact on supply chain issues. To counter these threats, it’s critical for businesses to lean towards vigorous supply chain strategies, including training staff, encrypting data, and updating systems regularly to safeguard their supply chain operations.

Rising consumer expectations

In the modern digital landscape, customers are demanding quicker, more transparent, and customized service experiences from companies. These heightened expectations have transformed how supply chains function, compelling businesses to revise their operational strategies and embrace new technologies. Pivotal customer demands influencing these changes include the desire for swift delivery, the capability to track orders in real-time, and the expectation for products and services to be customized to individual needs. To succeed in this fast-paced and digitised climate, companies are turning to cutting-edge solutions like automation, real-time order tracking, and predictive analytics.

Port congestion

Ports play a crucial role in the global trade network by enabling the movement of goods across international borders. However, many major ports around the world are currently facing substantial issues with congestion, resulting in delays and complex logistics. Several factors can be attributed to congestion. Firstly, the rapid growth of surging global trade can potentially shrink the ports’ capacity to manage increased cargo volume. Secondly, outdated infrastructure and a lack of automation cause bottlenecks in the movement of goods. Thirdly, labor problems, including strikes and workforce shortages, further reduce operational efficiency, exacerbating supply chain issues by affecting productivity. And lastly, the COVID-19 pandemic had unrelenting effects by causing backlogs and further congestion as it disrupted usual shipping routines. These challenges necessitate a need for businesses to invest in updated infrastructure, implement automation and digital solutions, and improve collaboration among supply chain stakeholders.

Demand Forecasting

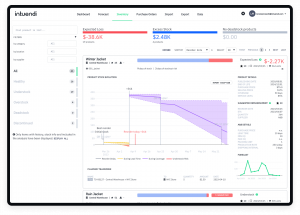

The ability to accurately predict customer demand is an essential component of effective supply chain management, yet it is a task fraught with difficulties. Companies often face the dilemma of having too much or too little inventory, or not aligning their production effectively, due to a number of challenges. Consumer preferences can shift rapidly and are difficult to anticipate. Unforeseen events such as natural disasters, economic changes, or political unrest can also significantly impact demand in unpredictable ways. Additionally, the intricate nature of today’s global supply chains adds a layer of complexity to demand forecasting, particularly across diverse markets. Inaccuracies in forecasting can facilitate inflated inventory costs, lost sales, and inefficient production. In response to these challenges, many companies are now leveraging advanced analytics and machine learning technologies to enhance their ability to forecast demand and respond more agilely to market changes.

Demand forecasting difficulties

Demand forecasting difficulties

Accurately predicting customer demand is crucial for effective supply chain management, albeit it creates challenges for businesses. Shifts in consumer preferences, unforeseen events like natural disasters or economic changes, and the complexity of global supply chains all contribute to the difficulty of forecasting demand. Discrepancies in forecasting can incite increased inventory costs, lost sales, and inefficient production. To mitigate such obstacles, many companies are turning to data-driven approaches and advanced technologies to improve their demand forecasting and respond more effectively to market changes.

Material scarcity

Material scarcity is causing shortages of critical raw materials or components in various industries, causing impending disruptions in supply chain operations and production processes. This scarcity can be attributed to factors such as geopolitical tensions, environmental issues, and increased demand. Industries like electronics, automotive, and construction are facing the brunt of these shortages. To circumvent this lack, companies are looking for alternative materials, diversifying their suppliers, and implementing recycling and circular economy initiatives.

Effects of the pandemic

The COVID-19 pandemic has had a profound and lasting impact on global supply chains, exposing vulnerabilities and causing disruptions. Factory closures, labor shortages, transportation delays, and shifts in consumer demand can jeopardize supply chain efficacy. While the acute phase of the pandemic has subsided, its lasting effects continue to be felt. Companies are prioritizing the implementation of more resilient supply chains by increasing inventory levels and opting for agile production methods to better manage future disruptions.

Demand volatility

Demand volatility refers to abrupt and unpredictable changes in consumer demand for products and services, which can originate from various factors like changing preferences or economic conditions. Consequently, this volatility can present a challenge to supply chain managers as it can potentially result in inefficiencies and increased costs. Strategies to cope with demand volatility consist of implementing better forecasting techniques, maintaining flexible production processes, optimising inventory levels, and diversifying product portfolios. Managing demand volatility effectively is essential for businesses to stay profitable and efficient in a dynamic market.

Transportation failure and delays

Efficient transportation is the backbone of any well-functioning supply chain, but failures and delays can cause dire disruptions. These can stem from vehicle breakdowns, weather events, labor strikes, accidents, and security incidents. Such issues can lead to stockouts, production delays, and increased costs for businesses. To prevent the cascading effects of these problems, companies are investing in strong transportation management systems, using a variety of transportation methods, and maintaining strong relations with logistics providers.

Supplier Relationship Management

In contemporary complex and interconnected supply chains, supplier relationship management is indispensable. Such relationships with suppliers are established upon open communication, setting clear expectations, regular evaluations, and building long-term partnerships with suppliers. Strong relationships enhance benefits such as improved quality control, cost savings, and early detection of potential supply chain issues.

Supply chain fragmentation

Supply chain fragmentation occurs as the consequence of disconnected or siloed operations within different parts of the supply chain, generating inefficiencies and risks. Mergers, outsourcing, lack of standardization, and global operations are a few key factors to consider. In an attempt to combat fragmentation, businesses can adopt strategies such as effecting integrated systems, standardizing processes, collaborating with partners, and using digital technologies for real-time visibility and coordination.

Cost control challenges

A competitive business environment, characterized by rising costs, means it is paramount for companies to effectively control costs in their supply chain operations to stay profitable and competitive. However, finding the right balance between cost control and maintaining efficiency and responsiveness in supply chains is not an easy task. Some of the main challenges include increasing transportation and logistics costs, high inventory carrying costs, supplier pricing pressures, and the need for technology and infrastructure investments. To withstand these cost-related challenges, companies utilize strategic frameworks derived from data analytics, lean practices, contract renegotiation, exploring nearshoring or reshoring options, and investing in sustainable practices. It is important for companies to take a comprehensive approach to cost control, considering both short-term savings and long-term resilience in their supply chain. Learn more on supply chain metrics for monitoring KPIs in the supply chain in our article here.

Extended lead times

Extended lead time refers to the duration between placing an order and receiving the product and presents challenges in current global supply chains. Such delays can be anchored in factors like globalization, production delays, transportation disruptions, and supplier lead times. Some disadvantages related to extended lead times include increased inventory costs, decreased flexibility, and customer dissatisfaction. To adequately equip businesses, an implementation of strategies such as supply chain visibility tools, diversifying supplier networks, JIT manufacturing, and advanced demand forecasting is necessary.

Price fluctuations

Price fluctuations in supply chain operations are concomitant to aspects such as commodity market volatility, exchange rate fluctuations, changes in trade policies, and supply and demand imbalances. These fluctuations can impact budgeting, profitability, and production schedules. Businesses can implement hedging strategies, diversify supplier networks, use advanced forecasting tools, and renegotiate contracts with suppliers to diligently manage price fluctuations and enhance supply chain resilience and competitiveness in a dynamic global marketplace.

Organizational restructuring

Organizational restructuring encompasses making changes to the structure and processes of a company in response to market conditions and challenges. Think mergers and acquisitions, outsourcing or insourcing, vertical integration or disintegration, and process reengineering. Improved efficiency, agility, access to new resources, and better alignment with business objectives comprise some fundamental benefits of organizational restructuring. However, challenges such as integration complexities, change management, and disruptions to operations can arise. The winning formula for successful restructuring comprises clear communication, strong change management processes, and a phased approach to lessen risks and ensure a smooth transition.

Delays in supply chain processes

Delays in supply chain processes can have cascading effects on efficiency, costs, and customer satisfaction. Common causes include bottlenecks, inefficient processes, data issues, transportation challenges, and disruptions which often result in increased costs, production stoppages, and customer dissatisfaction. Moving towards lean practices, investing in technology, optimizing logistics, fostering collaboration, and creating contingency plans prepares businesses for unanticipated delays thus enhancing efficiency, customer service, and competitiveness in the global market.

Causes of Supply Chain Issues

Supply chain issues can arise from a combination of internal and external factors, making it difficult to manage and impacting business stability. Recognising these causes is crucial for creating successful risk mitigation strategies.

Internal factors

Internal factors within a company can also impact supply chain performance and lead to supply chain issues. Considerations like ineffective strategic planning, poor forecasting, inadequate technology, talent and training gaps, siloed organizational structure, inefficient procurement, and inadequate quality control comprise internal factors. Addressing these internal issues can improve supply chain resilience, efficiency, and competitiveness.

External factors

External factors can also have an unparalleled effect on supply chain operations, alongside internal factors. These external forces, such as regulatory changes, geopolitical tensions, natural disasters, economic downturns, technological disruptions, labor disputes, and cybersecurity threats, can pose challenges and disrupt supply chain networks. By consistently and vigorously monitoring and addressing these external factors, companies can improve the resilience and agility of their supply chains to navigate through various business environments effectively and mitigate supply chain issues.

Circumvent supply chain issues with the aid of AI-powered Demand Planning Software.

Effects of Supply Chain Problems

Unequivocally, the repercussions of supply chain issues can have widespread effects that go beyond just affecting day-to-day operations. These problems can impact different areas of a company, such as its financial performance, customer approval, overall competitive position, and reputation.

Decreased operational efficiency

One of the most direct effects of supply chain issues is a decrease in operational efficiency, causing production line stoppages, delays in order fulfilment, increased costs, and underutilisation of resources. Such inefficiencies are consequential to lower productivity, missed opportunities, and hinder a company’s ability to meet customer demand and compete in the market.

Economic losses and cost increase

Supply chain issues can mean potential economic losses and cost increases for businesses. This can range from revenue losses from stockouts or order cancellations and higher costs for materials to transportation due to disruptions, increased inventory carrying costs, and penalties for missed deadlines. Financial impacts can harm profit margins, cash flow, and hinder a company’s ability to invest in growth opportunities.

Damaged reputation and diminished customer trust

Reputation is an invaluable business aspect. Issues in the supply chain can alter a company’s reputation and customer relationships by causing delays, stockouts, and quality problems. In turn, lower customer satisfaction and loyalty, harm to the brand’s image, loss of trust, negative publicity, and backlash from customers can indicate a tainted reputation. Rebuilding trust and repairing a damaged reputation can be a lengthy and expensive process, highlighting the importance of prioritizing supply chain resilience to maintain a positive brand image and customer loyalty.

Management of Supply Chain Issues

Managing supply chain issues effectively is crucial for businesses to remain efficient, satisfy customers, and stay competitive in the long run. By implementing synchronized strategies and adopting industry best practices, companies can improve the flexibility and robustness of their supply chains, allowing them to overcome obstacles and take advantage of new possibilities.

Implementing resilient supply chain planning

Resilient supply chain planning involves taking a dedicated and comprehensive approach to managing risks and ensuring business continuity. Conducting risk assessments, diversifying suppliers, using supply chain visibility tools, fostering collaboration, implementing agile processes, and investing in analytics are some key devices that contribute to supply chain efficacy. Through prioritising resilience, businesses can maintain operations during unprecedented times.

Maintaining liquidity to manage financial health

In order to effectively manage financial health during supply chain disruptions, businesses must focus on maintaining liquidity. This can be achieved through strategies such as cash flow forecasting, diversifying funding sources, cost optimization, working capital management, and scenario planning. Ensuring a strong liquidity position and actively managing financial resources can help businesses weather storms, invest in resilience strategies, and recover from disruptions more quickly.

Diversifying sourcing strategies

Businesses are increasingly recognizing the importance of diversifying their sourcing methods to avoid being overly reliant on a single supplier or region. This can leave them vulnerable to supply chain disruptions. To address this risk, companies are implementing various strategies such as sourcing from multiple suppliers, exploring nearshoring and reshoring options, implementing supplier qualification programs, forming strategic partnerships with key suppliers, and conducting regular supplier risk assessments.

Collaborating with freight forwarders

Collaborating with freight forwarders is essential for businesses looking to drive success by means of efficient supply chain and logistics operations. Working with experienced and reliable freight forwarders, maximizes benefits such as access to vast global networks, compliance expertise, real-time tracking, risk management strategies, and customized logistics solutions. This collaboration can help businesses streamline operations, reduce costs, and improve supply chain agility.

Identifying alternative shipping ports

Port congestion is a major issue for global supply chains, causing delays and increased costs. To stay ahead of the curve, businesses are looking for alternative shipping ports. Strategies include mapping port networks, evaluating capabilities, analysing performance, collaborating with logistics partners, scenario planning, and considering regulatory factors. By incorporating alternative ports into their strategies, businesses can improve resilience and flexibility in responding to disruptions.

Enhancing demand forecasting

Ameliorating demand forecasting is essential for efficient supply chain planning. Businesses can enhance their forecasting by using synchronised data-driven methods, demand sensing, scenario planning, and continuous improvement. Through significant investments in this domain, businesses can optimise inventory levels, reduce excess stock, and improve responsiveness to market changes, leading to better supply chain efficiency and customer satisfaction.

Recap of Key Points

To conclude the current global business landscape is fraught with complex supply chain issues. Businesses must address issues such as labor shortages, cybersecurity threats, port congestion, and demand volatility to maintain efficient operations. Key takeaways include understanding the causes of supply chain issues, the severe consequences of disruptions, the importance of proactive management strategies, investing in technology and data analytics, and fostering strong relationships with stakeholders. Albeit challenges are inherent to business environments, proactive supply chain management can equip your business to remain resilient, efficient and profitable in a competitive and rapidly evolving environment. Businesses that thrive stand on the premise of anticipating challenges, deriving data-driven information through innovative technologies and prioritizing resilience and adaptability.