The term SKU (Stock Keeping Unit) is associated with a product (usually, but not always, a physical one) and identifies the most detailed disaggregate description of the product. Let me give an example – assume you produce shoes. They are your products.

The somewhat aggregated specifications of your product would be: a specific shoe model, in a specific color, made from a specific material.

A given shoe model might come with several available sizes. An SKU can be the code for identifying a specific size. It can even be something more disaggregated, like that size in a specific warehouse or retail store.

An SKU usually corresponds to detailed and specific product description. In other words, you can freely exchange two product items with the same SKU identification without any problem.

An SKU (and its uniquely identified code) is extremely important for inventory management and control. If the inventory is like a building, SKU’s are the bricks.

Businesses usually record historical data on the SKU level. Thus, any good inventory forecasting software solution will be based on the analysis of past sales data on a similar level. They usually do forecasting on the SKU level, too.

Let’s take shoes as an example. Sometimes inventory forecasting software solutions aggregate different SKUs and generate a forecast at a higher level of aggregation. As an instance, we might aggregate and forecast the inventory demand for that specific shoe type, disregarding the different sizes.

This way of producing inventory forecasts has some advantages. It is usually more precise for the aggregate forecasted demand, but there are also disadvantages. Sooner or later you will need to split your aggregate to the SKU level.

Why should you make the most out of your SKU level data?

A couple of reasons are as follows:

- SKU level data will allow you to know more details about your purchases and about the people who made them. You’ll learn about the favorite size or color of a given customer with the help of this data.

- Having all this information at hand, you will be able to improve your marketing strategies. As a result, you’ll send more relevant offers to your customers – ones that are actually in the scope of their interests.

Use your SKU level data to encourage your customers to buy more of what they want to buy. It will help you increase engagement, foster customer relationships, and their shopping experience.

Just keep in mind that regardless of your demand forecasting technique and tool, eventually you will be interested in SKUs. Not only for inventory demand forecasting, but also for the inventory and its control. You will need to replenish some SKUs and leave others untouched as they are beyond the level which triggers a new order.

SKUs are of crucial importance as they allow you to track your stock levels for each product and material type. This leads to higher optimization of your inventory levels and more productive inventory management.

Benefits of integrating a solid SKU plan into your business

- Improved Work Efficiency: Using SKUs helps everyone internal understand the products and their movements efficiently.

- Fewer Communication Errors: Having to deal with long product names and variant attributes can cause communication errors and affect the workflow. SKUs help reduces the occurrence of such errors and misunderstandings.

- Simplified Stock Taking: With the help of SKUs, the identification of variants becomes much simpler and easier. This way you can know if your inventory matches the actual stock levels.

- Product Prioritization: SKUs enable you to check out the sales volumes for each variant of your products. Some colors or sizes might be more in demand than others. Knowing your customers’ preferences, you can essentially optimize your production and increase your sales.

- Better Inventory Management: Having reorder points set on each variant on your SKU will highly improve the efficiency of your inventory.

Improve and optimize your SKU plan in order to take advantage of everything that SKUs bring to the table for a business owner or a manufacturer.

To sum up, SKUs are your products, described with all the details you need in order to keep inventory and cost under control.

SKU Planning

Let us look at how SKUs may be used in planning and SKU demand forecasting. Businesses usually record historical data on the SKU level. Any good inventory forecasting software solution would be based on the analysis of past sales data on a similar level, while additionally forecasting on the SKU level too, this is called SKU forecasting.

Let us look at the example of shoes. Occasionally, inventory forecasting software solutions aggregate different SKUs and generate a forecast at a higher level of aggregation. Your shoe company might aggregate and forecast the inventory demand for a specific show type while disregarding the different sizes.

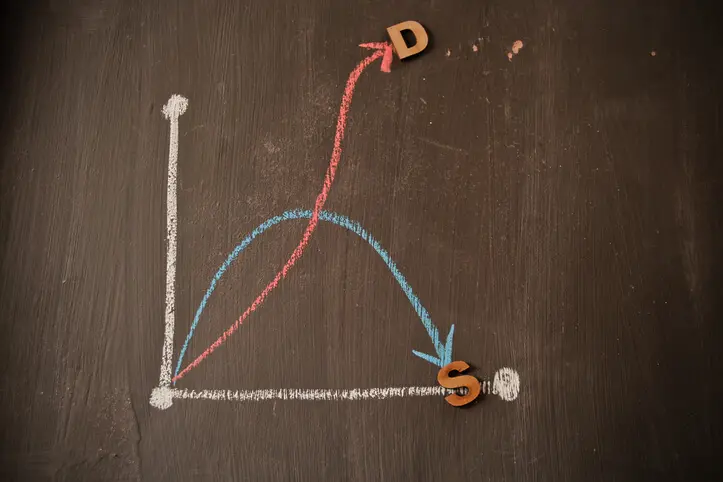

This way of producing inventory forecasts has both advantages and disadvantages. While it is usually more precise for the aggregate forecasted demand, sooner or later you will need to split your aggregate to the SKU level.

Forecasting a new SKU when no history is available

In recent posts we’ve talked about basic time series methods

and advanced time series methods for sales forecasting, We’ve

highlighted the core differences between demand and sales forecasting.

But in all of these blog pages, we’ve assumed that enough history of an SKU is available in order to get a good forecast and, obviously, it is not

always the case. How can we deal with a very very short history or with a brand new product in the inventory?

Things get hard when there is no sales data, especially for a tool that relies on it, as it is for demand forecasting software. The more history, the more accurate

the predictions. A thumb rule that is usually true.

However, the time series of sales is not the only source of value. But we’ve to analyze different cases.

A new SKU that replaces an old SKU

This is the case of a new model of a product series. Let’s think about a smartphone: the new model is appearing in the market

with huge investments in marketing by the manufacturers. The first thing that comes to mind is that the new SKU will replace

the previous and the missing time series history could be inherited from the old SKU. Oh, awesome, close to victory.

However, the new smartphone will cost more than the previous in the first weeks, thus it’s not plausible that the sales

of the old model will drop to zero instantly. That is, the movement of sales from the old SKU to the new SKU is gradual and

it is commonly called cannibalization.

Thus, a demand forecasting software can exploit such relationship and do a good forecast, although several factors have to be considered

and it deserves a distinct blog post.

A new SKU comes with a lot of information

Even if no history is available, since it is new, an SKU comes with a lot of useful information. Here we’re going to briefly

introduce a few ideas on how to get data to work with.

A new SKU, let’s say a new model of white ripped jeans, has intrinsic data. Firstly, it is a pair of white jeans, then it is a pair of jeans.

Oh, will it be sold in Arizona? Yes, let’s have a look at the sales history of white jeans in Arizona. Uh, a lot of information.

This information can be combined and clustered in order to get insights into our brand new white ripped jeans future demand.

Finally, no matter if no sales history is available. In the era of Big Data, the main concern is to extract value from data, whichever

is the source or the semantic. For a new SKU, several solutions can be exploited in order to get a good forecast.