When managers face with supply chain management or inventory management, the amount of work can be proportional to the business size.

Whichever is the level of the organization of human resources of the company, dealing with a huge inventory may be critical.

Let’s say you want to perform demand forecasting on

your catalog of goods you produce or you supply. Although there will be a small set of so-called

best sellers which represent the greatest part of the revenues, you may be interested in having a general overview of the future evolution

of all your inventory. And then, given the estimation, who cares about inventory replenishment optimization?

Oh, too much work!

Yes, it is. Too much work. Too many SKUs to forecast, to analyze and then to manage, trying to understand when it’s time to reorder a product.

Since out of stock events should be avoided as much as possible and excessive stock levels are critical as well.

Now, let’s give an example of how it can be hard. Let’s figure out four hours a day of work on demand forecasting and inventory optimization

and an inventory of 10’000 products. So we have approximately 90 hours per month. How much time for each product? Uhm, nearly 30 seconds!

Not too much.

90 hours x 3’600 seconds / 10’000 products ≈ 30 seconds

Ok, let’s switch the point of view. You are an efficient and brilliant forecaster and inventory optimizer, you need only an average time of 5 minutes to understand

all the dynamics around a single SKU. You’re going to need 833 hours, 104 full-time working days, approximately 5 months when the forecasting frequency is monthly.

You can’t do that. Then, you need 5 full-time employees or 10 employees who guarantee four hours of forecasting per day.

5 minutes x 60 seconds x 10’000 products / 3’600 seconds ≈ 833 hours

You can’t do that. You need 5 full-time employees or 10 employees who guarantee four hours of forecasting per day.

A lot of human resources and money! And we didn’t even tell how much is tedious and error-prone!

Predictive Analytics reduces the effort

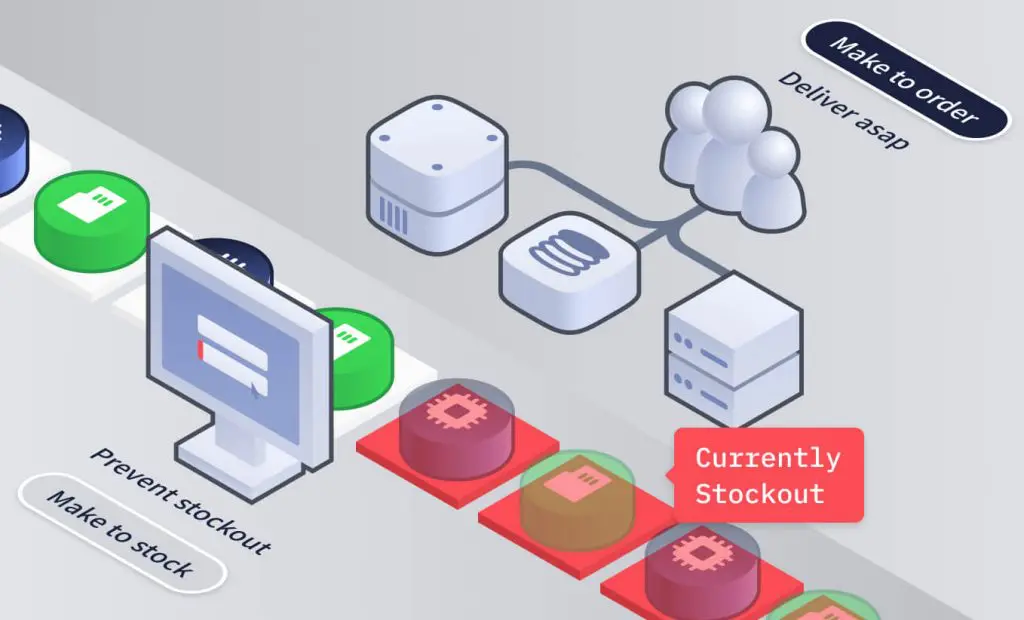

How can we deal with this huge amount of work? With new solutions, as predictive analytics software is. In this case, demand forecasting and inventory replenishment solutions will automate all the operations we talked about. From the estimation of the demand for the next month to the suggestion of a replenishment of an SKU on the next Monday. In a time which is a very small portion of that of the example, let’s say half an hour in the worst case.

Thanks to such a solution, a manager has just to worry about supervising and monitoring the whole process, override forecasts or reorder points, if need be.

Greater quality of the forecasts, less work time, more robustness, fewer errors.