The future of supply chain optimization (and spoiler alert: also container optimization) just got smarter… We are happy to unveil a major upgrade to our optimization engine, introducing new multi-purpose capabilities designed to make decision-making faster, more accurate, and more human-centric.

At the heart of this evolution is M.i.l.o. (Multi-purpose intelligent learning optimization), our re-engineered optimization engine that continuously learns from real-world data to help retailers and brands make sharper, faster, and more confident decisions.

With the upgrade of M.i.l.o, we’re building the future of optimization at Intuendi, where AI amplifies human expertise, speeds up decisions, accelerates workflows, and turns complexity into clarity. We are dedicated to evolving and giving our customers a lasting competitive edge.

Smarter Container Optimization, Real Results

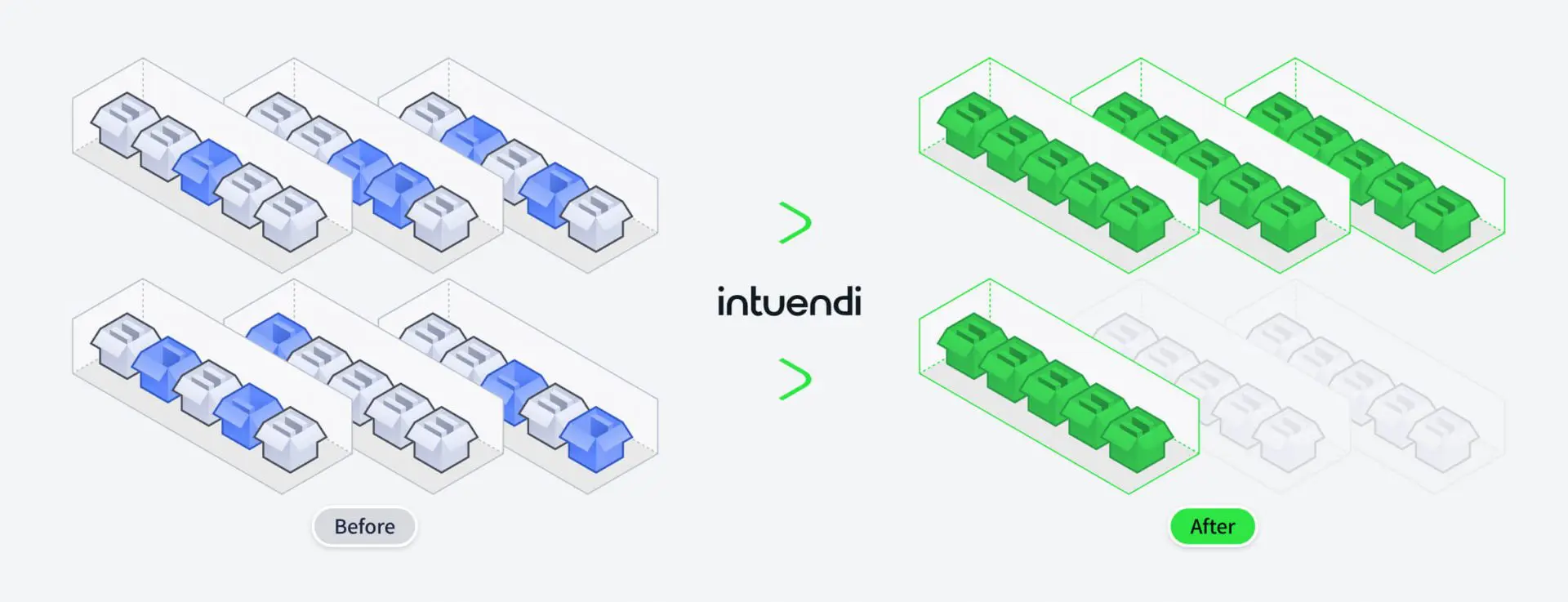

The first application of M.i.l.o. appears through our upgraded container optimization feature, a long-requested solution to one of the toughest challenges in global supply chain management: how to fill and ship containers efficiently without wasting space, time, or money.

Traditionally, planners rely on manual calculations or simple heuristics to split shipments, methods that are often slow, error-prone, and suboptimal. M.i.l.o. changes that by automatically identifying the best possible configuration in minutes, helping companies balance constraints like space, weight, cost, and expected margin while retaining full control of the final decision.

So far, M.i.l.o. has demonstrated a 33% reduction in container requirements while maintaining utilization rates above 90%.

Here’s a look at how it performed in a simulated shipment scenario of 110 parcels:

| Strategy | Containers Used | Avg. Volume Utilization | Avg. Weight Utilization | Result |

| Sort by Volume | 30 | 64% | 65% | Poor utilization of last container |

| Sort by Weight | 30 | 64% | 65% | Inefficient split across containers |

| M.i.l.o. Optimization | 20 | 95% | 97% | 33% fewer containers, optimal efficiency |

Key takeaway: M.i.l.o. cut container needs from 30 to 20 while maintaining utilization above 90%. In real-world operations involving hundreds or thousands of SKUs, this translates to substantial cost savings, faster planning cycles, and improved logistics performance.

average container utilization

reduction in containers used

Why It Matters for Supply Chain Leaders

Container optimization is just the beginning. Because M.i.l.o. is designed for multi-dimensional optimization, we plan to extend its use across the entire supply chain, from stock allocation and network optimization to replenishment and merchandising decisions.

This upgrade in M.i.l.o. represents a breakthrough in how AI can be applied to real-world supply chain constraints.

The implications are vast:

- Fewer containers shipped means lower freight costs and carbon emissions.

- Faster planning frees up time for strategic decision-making.

- Higher accuracy reduces stockouts, overstocking, and cash tied up in inventory.

By embedding M.i.l.o. into our full platform, we are positioning ourselves not just as a forecasting and demand tool, but as an intelligence and design partner for modern, high-growth, high-complexity retail and commerce companies.

Powering Smarter, More Sustainable Supply Chains

From South America to Europe, our customers are already seeing measurable results. La Casa de las Baterías, a leading battery and energy systems company, used an early version of M.i.l.o. to cut planning time and improve shipment efficiency across its network and countries.

With every upgrade, we continue progress toward our mission to help supply chain leaders build resilient, efficient, and data-driven operations where AI acts as an intelligent collaborator, not a replacement for human insight.