Contemporary business climates are fast-paced. Intrinsic to the dynamism are supply chain operations that are integral to driving profitability and fulfilling customer expectations. The lean supply chain methodology is a valuable tool in this regard, providing a tried-and-tested strategy for eliminating inefficiencies, simplifying workflows, and enhancing overall performance. By adopting lean principles, organisations can realise substantial savings, increase flexibility in their operations, and provide exceptional levels of service to their customers.

What is a Lean Supply Chain

A lean supply chain is a meticulously crafted system aimed at eradicating inefficiencies and optimising productivity throughout the entirety of the supply chain spectrum, spanning from sourcing raw materials to delivering the end product. Its primary objective is to enhance customer value while minimising superfluous activities that do not contribute to the overall value proposition, such as surplus inventory, unnecessary transportation, and redundant procedures. Lean supply chains differ from traditional supply chains by being more flexible and efficient. They prioritise producing the correct products in the appropriate quantities at the optimal time, all while reducing waste and enhancing value for customers.

History of Lean Methodologies

The roots of lean methodology can be traced back to the Toyota Production System (TPS), which was developed by the Japanese automaker Toyota in the mid-20th century. Taiichi Ohno, a visionary engineer at Toyota, established the core principles of lean manufacturing, such as Just-In-Time (JIT) production and the continuous improvement philosophy known as Kaizen. These principles have since been widely embraced across various industries, extending beyond manufacturing to areas like supply chain management. Today, companies leverage lean methodologies to optimise their operations, cut costs, and elevate customer experience.

Key Principles of Lean Supply Chain

The lean supply chain philosophy is based on core principles that direct decision-making and operations. These principles act as a guide, helping companies stay committed to reducing waste, constantly enhancing processes, and providing value to customers.

Waste Reduction

Lean supply chain principles focus on minimizing waste by identifying and eliminating activities that do not add value to the final product or service. Waste is defined as any non-value adding activity or resource in the production process. The seven common forms of waste include overproduction, waiting, transportation, extra processing, inventory, motion, and defects. By addressing these sources of waste, companies can streamline their supply chain operations, cut costs, and enhance overall efficiency.

Continuous Improvement

Continuous improvement, also known as Kaizen, is a foundational principle in lean supply chain management that promotes a culture of perpetual growth and enhancement. In a lean supply chain, every aspect of operations is continuously assessed and refined to drive efficiency and effectiveness. This philosophy is reinforced by strategies like the PDCA cycle and the 5S system, which emphasise ongoing evaluation and optimisation. By embracing a mindset of continuous improvement, organisations can remain adaptable, responsive, and competitive amidst dynamic market conditions.

Reactive Production

In a lean supply chain, production is intricately linked to immediate customer needs. This proactive production method, referred to as pull production, guarantees that goods are only produced when there is a genuine demand, thereby decreasing surplus inventory and mitigating the likelihood of products becoming obsolete. Strategies like Kanban systems and vendor-managed inventory (VMI) empower organisations to harmonise production with customer requirements, ultimately cutting down on waste and bolstering adaptability to shifts in the market.

Implementation Strategies for Lean Supply Chain

Creating a lean supply chain necessitates a thoughtful and deliberate strategy. Below are some practical approaches to take into consideration.

Supplier collaboration

Effective collaboration with suppliers is crucial for creating a lean supply chain. By developing strong relationships with suppliers, companies can streamline operations, minimise waste, and boost efficiency. Key strategies for successful supplier collaboration include transparent communication, joint process improvement efforts, and supplier development programs. Companies like Toyota and Walmart serve as examples of how effective supplier partnerships can lead to cost reductions, enhanced quality, and improved responsiveness.

Just-In-Time (JIT) Production

Just-In-Time (JIT) production is a key component of lean supply chain management, focusing on producing goods only when there is customer demand. This approach helps to minimise excess inventory, reducing storage costs and the risk of obsolete products. To successfully implement JIT, companies need to accurately forecast demand, synchronise production schedules with real-time demand signals, and ensure reliable supplier delivery. While JIT production offers numerous advantages, such as increased efficiency and cost savings, it also comes with challenges like the potential for stock-outs and a greater reliance on supplier reliability. Therefore, companies must carefully weigh these risks against the benefits of JIT production.

Read our case study to discover methods for reducing sickouts while increasing sales and ROI.

Integrating Technology

Technology is essential for maximising the efficiency of lean supply chain operations. By utilising the appropriate technologies, businesses can improve transparency, simplify procedures, and facilitate informed decision-making based on data. Some essential technologies for lean supply chains include:

Enterprise Resource Planning (ERP) Systems

ERP systems are essential for integrating and managing various business functions such as procurement, production, inventory management, and logistics. In a lean supply chain, these systems provide real-time insights that improve coordination and decision-making. Companies like Dell and Toyota have effectively utilised ERP systems to enhance operational efficiency by streamlining processes and reducing wastage.

Radio Frequency Identification (RFID) Technology

RFID technology allows for the automatic tracking and identification of goods in the supply chain by attaching RFID tags to products or containers. This technology has been successfully used by companies such as Walmart and the U.S. Department of Defense to improve inventory management, logistics, and overall supply chain efficiency.

Data Analytics

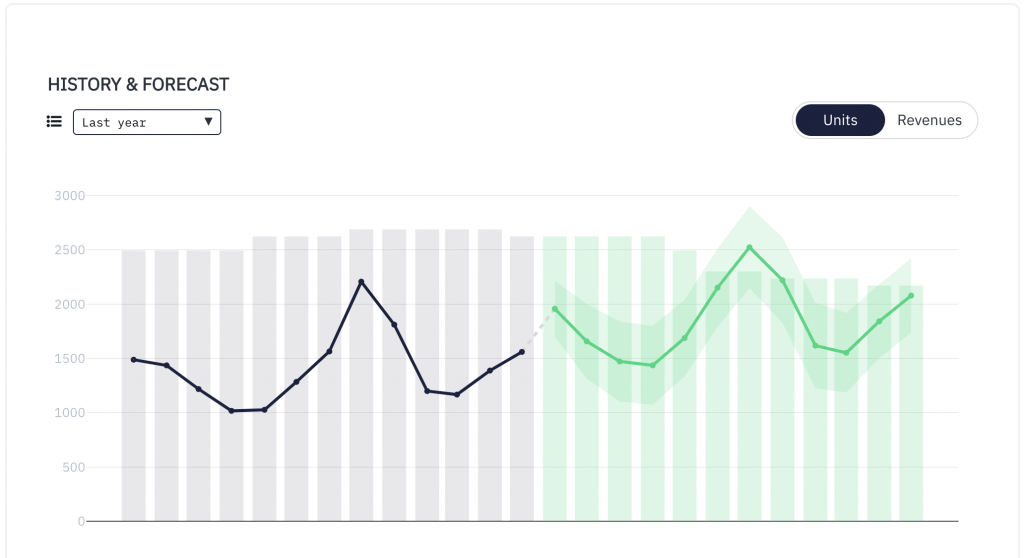

Data analytics is essential for making informed decisions in efficient supply chains. By analysing data from different sources like customer orders, supplier performance, and production metrics, companies can identify and solve problems, improve processes, and find opportunities for growth. Advanced analytics tools like predictive modelling and machine learning can also help companies predict demand changes, manage inventory effectively, and address potential issues before they occur.

Visit Intuendi Forecast to learn more about our Demand Forecasting Software.

Management and Operations in Lean Supply Chains

The effectiveness of a streamlined supply chain is greatly dependent on skilled management and operational proficiency. Embracing a lean mentality and integrating lean principles across all levels of the organisation are essential for maximising the advantages of this approach.

Role of Management

Management plays a crucial role in establishing and maintaining a lean supply chain culture in an organisation. Effective lean management involves senior leadership actively endorsing lean principles, fostering a culture of continuous improvement and waste reduction, empowering employees at all levels to identify and address inefficiencies, and providing comprehensive training programs. Companies like Toyota and Danaher Corporation exemplify the success that can be achieved through strong leadership and a deeply ingrained lean culture, leading to significant improvements in efficiency, quality, and profitability.

Warehousing

Lean principles can be applied to warehousing operations to improve efficiency by optimising space utilisation, reducing waste, and enhancing order fulfilment processes. Strategies for implementing lean warehousing include layout optimisation, visual management, and cross-docking. Companies like Amazon and Walmart have successfully implemented these principles, leading to improvements in order accuracy, throughput, and cost savings.

Transportation

Efficient transportation is a crucial element of lean supply chain management, impacting costs, lead times, and customer satisfaction. Strategies such as route optimisation, mode selection, and milk-run logistics can help minimise fuel consumption, reduce travel time, and consolidate delivery points for cost and emission reductions. Companies like Dell and Zara have successfully employed these strategies to save costs and better meet customer demands.

Customer Integration

Integrating customers into the lean supply chain process is crucial for ensuring efficient and effective delivery of value. Strategies for customer integration include Voice of the Customer (VoC) programs, collaborative forecasting and planning, and co-creation and customisation. Companies like LEGO and Nike have successfully implemented these strategies, leading to closer relationships with customers and products that better meet their expectations.

Impact and Benefits

Introducing a streamlined supply chain can result in considerable advantages and favourable outcomes for businesses in a multitude of sectors. By adopting lean methodologies and tactics, organisations can realise substantial enhancements in financial performance, operational efficiency, and client contentment.

Boosting Profits

The main benefit of a lean supply chain is its ability to increase profitability by reducing waste, cutting inventory costs, and improving efficiency. Companies like Toyota, Dell, and Walmart have seen significant cost savings and profit increases by implementing lean practices. In addition to saving money, a lean supply chain can also lead to faster time-to-market, better customer responsiveness, and higher product quality, ultimately driving increased sales and customer loyalty.

Streamlining Processes

Lean supply chain principles focus on removing activities that do not add value and improving processes. By using tools like value stream mapping and continuous improvement methods, companies can identify and eliminate unnecessary steps and inefficiencies in their supply chain. This streamlining not only reduces waste and boosts efficiency but also increases agility and responsiveness. This allows companies to quickly adjust to market changes, customer needs, and supply chain disruptions, giving them a competitive advantage in fast-paced business environments.

Enhancing Customer Satisfaction

In essence, the main objective of a lean supply chain is to provide excellent value to customers by matching production with demand, cutting lead times, and enhancing product quality. Companies such as Amazon and Zara have successfully utilized lean principles to offer customers quicker delivery, more product choices, and a more tailored shopping experience. These enhancements in customer satisfaction can result in greater loyalty, positive referrals, and improved customer retention rates, ultimately leading to business expansion and sustained success.

Challenges in Lean Supply Chains

Although there are significant advantages to adopting a lean supply chain, companies may encounter various obstacles during the process. It is important to anticipate and deal with these challenges in a proactive manner in order to achieve a successful transition to a lean system.

Risk of stock-outs

Lean supply chains, which minimise inventory levels and rely on just-in-time production, are at risk of stock-outs due to unexpected spikes in demand or supply chain disruptions. Stock-outs can lead to lost sales, dissatisfied customers, and increased costs. To mitigate this risk, companies should use robust demand forecasting, maintain communication with suppliers, and have contingency plans in place. Safety stock levels, supplier diversification, and flexible production capacity can also help reduce the impact of stock-outs.

Vulnerability to External Risks

Lean supply chains, which focus on efficiency and waste reduction, are at risk of being disrupted by external factors like supply chain disruptions, natural disasters, political instability, and market fluctuations. These disruptions can interrupt material flow, stop production, and impact a company’s ability to meet customer demand. The COVID-19 pandemic highlighted these vulnerabilities in lean supply chains, as companies struggled with shortages, transportation issues, and fluctuating demand. To address this vulnerability, companies need to implement a comprehensive risk management approach and enhance the resilience of their supply chains by diversifying suppliers, creating contingency plans, and promoting collaboration within the supply chain network.

Risk Management Strategies

Efficient risk management plays a vital role in navigating the complexities of lean supply chains and securing lasting viability and prosperity. It is imperative for companies to adopt proactive measures in order to recognise, evaluate, and address potential risks in a timely manner, preventing them from evolving into major disruptions.

Risk Identification

The first step in risk management involves identifying and assessing potential risks within the supply chain. This includes creating a detailed map of the supply chain network, evaluating the likelihood and impact of various risks, and continuously monitoring for emerging risks. Companies can use data analytics, risk assessment tools, and industry reports to gain insights into potential risks and their impact on operations.

Building Resilience

Companies must implement strategies to enhance the resilience of their lean supply chains in order to withstand and recover from disruptions. Some key strategies include supplier diversification, contingency planning, inventory buffers, supply chain visibility, and collaboration and information sharing. Companies like Toyota and Cisco Systems have successfully implemented these strategies to maintain supply chain resilience and minimise disruptions, even during major global events like natural disasters and pandemics.

Conclusion

In conclusion, adopting a lean supply chain can benefit companies by improving efficiency, reducing costs, and enhancing customer satisfaction. This approach involves minimizing waste, improving processes, and responding quickly to production demands. Challenges such as inventory shortages and disruptions can be overcome by promoting lean management, using technology, and managing risks. Implementing lean strategies can lead to increased profits, streamlined operations, and satisfied customers, giving companies a competitive edge and enabling sustainable growth in a dynamic marketplace.

Request A Demo