Your finance team lives in one system, your sales team uses a separate CRM, and your warehouse runs on a completely different platform. None of them talk to each other. Sound familiar? This common business problem, known as “data silos,” creates inefficiency, errors, and a frustrating lack of visibility across the organization. The solution to this chaos is Enterprise Resource Planning (ERP), a powerful system designed to unify all these disparate functions into a single, cohesive whole.

What Is Enterprise Resource Planning (ERP)?

At its heart, ERP stands for Enterprise Resource Planning. The easiest way to understand it is to think of an ERP system as the central nervous system of a business. Its core purpose is to integrate all essential business processes—like finance, supply chain, manufacturing, services, and human resources—into one single system that operates on a shared database.

This integration is the key. When everyone in the organization, from the CEO to the warehouse clerk, is working with the same, up-to-the-minute information, you achieve a “single source of truth.” This eliminates data duplication, drastically reduces errors, and gives leaders a real-time, holistic view of the entire business. And while a strong financial module is a critical part of any ERP, a true ERP system is far more comprehensive than just accounting software.

The Core Business Benefits of an ERP System

Implementing an ERP is a major strategic decision, not just a software upgrade. When done correctly, an ERP System Implementation drives significant and lasting value across the entire organization.

The most immediate benefit is streamlined operations and enhanced efficiency. By automating routine tasks, standardizing processes, and ensuring a smooth flow of information between departments, an ERP system eliminates bottlenecks and frees up employees to focus on more value-added work. This leads directly to improved data accuracy and visibility. With all data housed in a single location, you can generate real-time reports and access business intelligence that leads to better, faster, and more informed decision-making.

Furthermore, these efficiencies often translate into significant cost reduction. By optimizing inventory levels, reducing administrative work, and improving production planning, an ERP helps trim waste and lower operational costs. Finally, a good ERP system provides scalability. It is designed to grow with your company, able to handle more transactions, users, and business complexity without needing to be replaced.

How Does an ERP System Work? The Key Modules

The power of an ERP system comes from its modular design. Different business functions are handled by specific “modules,” which are all deeply interconnected and share the same central database. Here are some of the most common ones:

Financial Management

This is the bedrock of nearly every ERP system. The finance module manages the general ledger, accounts payable, accounts receivable, budgeting, and financial reporting. It provides a real-time, comprehensive view of the company’s financial health and ensures regulatory compliance.

Supply Chain Management (SCM)

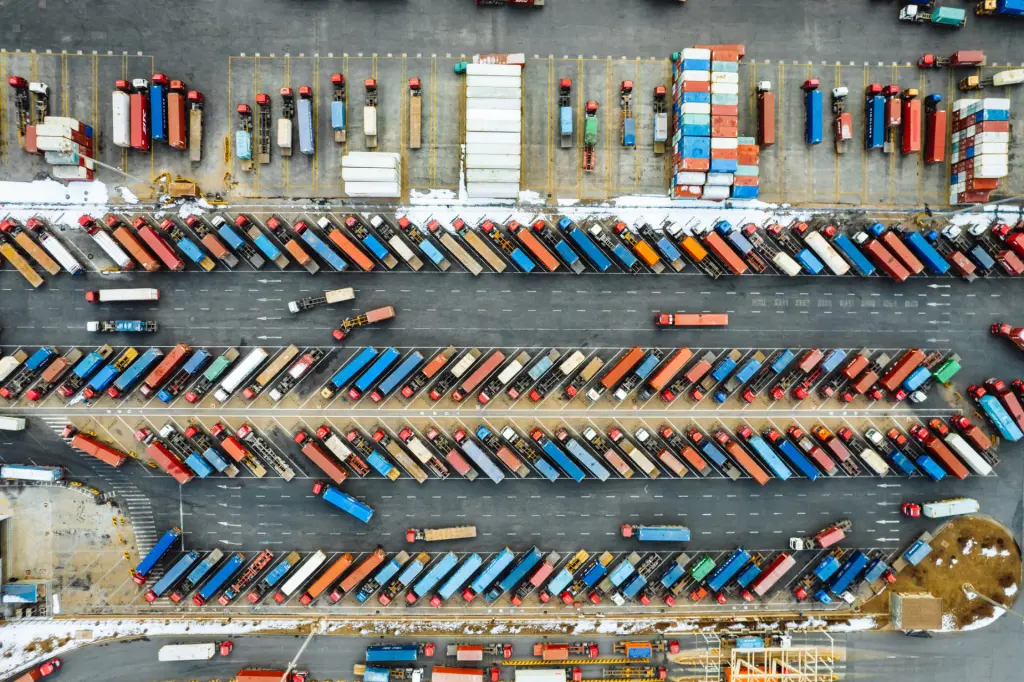

This module is the logistical heart of the business. It covers everything from the procurement of raw materials and supplier management to inventory control, order processing, warehousing, and shipping. An SCM module helps optimize the entire flow of goods from the supplier to the end customer.

Human Capital Management (HCM) / Human Resources (HR)

The HCM module centralizes all employee-related information and processes. Its functions typically include payroll, benefits administration, recruiting and onboarding, time and attendance tracking, and performance management.

Customer Relationship Management (CRM)

While sometimes a standalone system, integrating CRM functionality into your ERP provides a true 360-degree view of your customers. It links sales activities, marketing campaigns, and customer service interactions directly with financial and inventory data, so a salesperson can see a customer’s order history and payment status in one place.

Manufacturing and Production

For companies that make things, this module is essential. It manages critical functions like production planning, work order management, shop floor control, quality assurance, and Material Requirements Planning (MRP)—the manufacturing-focused software that was the historical predecessor of the modern ERP.

Types of ERP Systems: Deployment Models

One of the biggest differentiators between ERP systems today is how they are deployed—that is, where the software and your data physically reside.

On-Premise ERP

This is the traditional model where a business buys the software licenses and hosts the ERP system on its own servers and hardware, managed by its own IT staff. This approach offers a high degree of control and customization, but it comes with a very high upfront investment, significant ongoing maintenance costs, and the full responsibility for data security.

Cloud ERP (SaaS)

This is the modern, now-dominant model. With a cloud ERP, the software is hosted on the vendor’s servers and accessed by your business over the internet, typically on a subscription basis (Software-as-a-Service). The benefits are compelling: much lower initial costs, easy scalability, automatic updates handled by the vendor, and access to advanced technologies like AI and machine learning.

Hybrid ERP

This “best of both worlds” approach combines cloud applications for some functions (like CRM or HR) with a traditional on-premise system for others. Companies often use this model to keep core financials or highly specialized manufacturing processes on-premise for security or legacy reasons, while taking advantage of the flexibility of the cloud for other functions.

How to Choose the Right ERP System for Your Business

Choosing an ERP is a long-term commitment that will shape your business for years to come. It’s a process that requires careful thought and planning.

Step 1: Assess Your Business Needs and Processes

Before you look at a single vendor, look in the mirror. Map out your current processes and identify your biggest pain points. Where are the data silos? Which workflows are most inefficient? You must clearly define your business goals and technical requirements before you start shopping.

Step 2: Evaluate Key Factors and Vendors

Once you know what you need, you can start evaluating your options. Key criteria include industry fit (does the vendor have proven experience in your sector?), scalability (can the system grow with your business?), integration capabilities (can it connect to other critical tools you use?), and vendor reputation and support. Some of the most well-known vendors in the market include SAP, Oracle NetSuite, Microsoft Dynamics 365, and Infor.

Step 3: Plan for Implementation and Change Management

Remember, you’re not just buying software; you’re buying a major business transformation project. A successful outcome depends on a clear implementation plan, a solid data migration strategy, and, most importantly, robust change management. Training your employees, getting their buy-in, and supporting them through the transition is absolutely crucial for success.

Is an ERP System Right for You?

An ERP system is an incredibly powerful strategic tool. It breaks down the walls between departments, drives operational efficiency, and provides the visibility needed to compete in the modern world. It is a major investment of time, money, and resources, but when it is chosen wisely and implemented correctly, the return on that investment is undeniable.

If you’re tired of running your business on a patchwork of disconnected spreadsheets and applications, it’s time to take the next step. Begin with a thorough assessment of your own business processes and pain points. That first step is the beginning of your journey toward a more integrated, efficient, and profitable future.

Looking for a smarter way to unify your operations and optimize your inventory?