The Company

La Casa de las Baterias is a prominent regional company specializing in batteries and energy systems. Their services include battery installation across more than 75 branches in four Central American countries: Panama, El Salvador, Costa Rica, and Guatemala. Additionally, the company offers home services, catering to battery, fuel, and tire change needs. Their clientele includes vehicle fleets, industrial traction equipment, energy backup systems, photovoltaic solar energy consumers, and they also operate a minor mechanical and electromechanical workshop.The Problem

Casa de la Baterias has experienced steady growth in recent years. However, during and after the pandemic, challenges like extended lead times and delayed shipments from suppliers emerged. Furthermore, the company’s growth plan set higher targets and expectations, introducing new complexities in daily operations. The uncertainties surrounding lead times and the ever-changing context impacted product availability performance and hindered timely deliveries to meet growing demand. To tackle these challenges, Casa de la Baterias opted to invest in AI technology, with a specific focus on advanced demand planning activities.

“The complexity of the data reached a point where we had to spend tens of hours building complex spreadsheets with hundreds of formulas just to determine what we needed to purchase the next month. Many costly mistakes were made.”

Juan Raúl Gómez, Regional Procurement Manager

The Main Challenges

Planning demand for a business like Casa de las Baterias involves dealing with mid-to-long lead times, spanning from two to six months, and the constraint of high minimum order quantities when placing orders with suppliers. Effective advanced planning becomes essential under such circumstances. It is vital to factor in uncertainties and differentiate product categories to minimize understock risks for Best Sellers while reducing the probability of overstocking slow-moving products. While their product catalog comprises nearly 1,000 SKUs, which is moderately sized, the complexity arises due to the need for purchasing in containers. This necessitates optimizing container space through a smart fulfillment policy to minimize overstock risks and optimize storage for the customer.The Solution

Upon collaborating with Intuendi, Casa de las Baterias benefitted from a team with a profound understanding of planning processes, the company’s consistent growth, and a strong focus on optimizing costs and revenues. The primary objective was to restore desired product availability, sustain growth, and solidify their leadership position despite the competitive landscape. Intuendi’s solution involved advanced demand forecasting, powered by AI, coupled with historical data analysis and external variables influencing demand. Additionally, the implementation of inventory optimization was essential to identify real-time understock risks for all products. To precede inventory optimization, an in-depth ABC analysis was conducted, going beyond the ABC dimension, to identify products worthy of investment and slow-moving ones requiring controlled overstock risks. The implementation of purchase order suggestions with advanced container space optimization capabilities formed the actionable part of the project, targeting demand planners and purchasing office employees, thus providing a tangible daily demand planning dimension.The Result

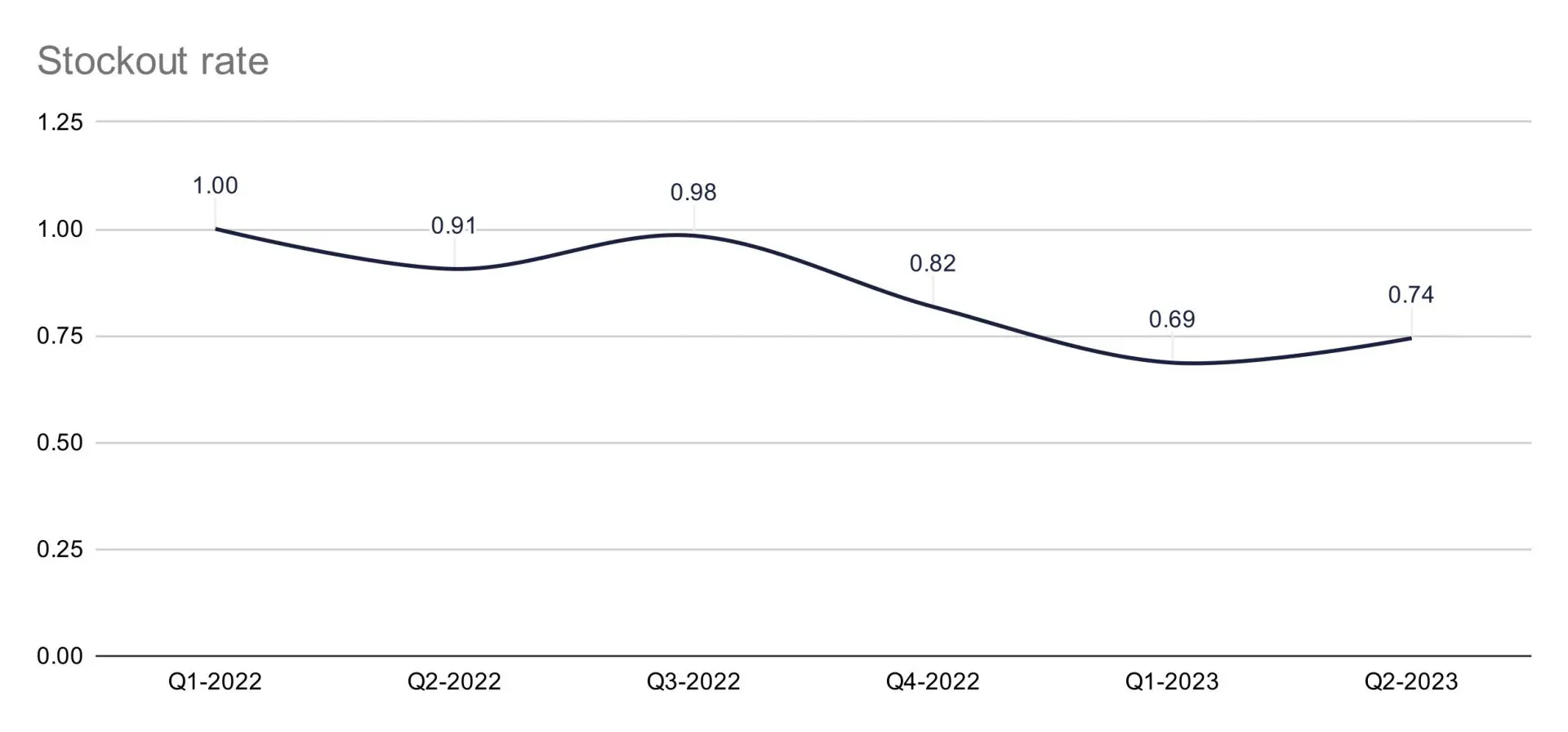

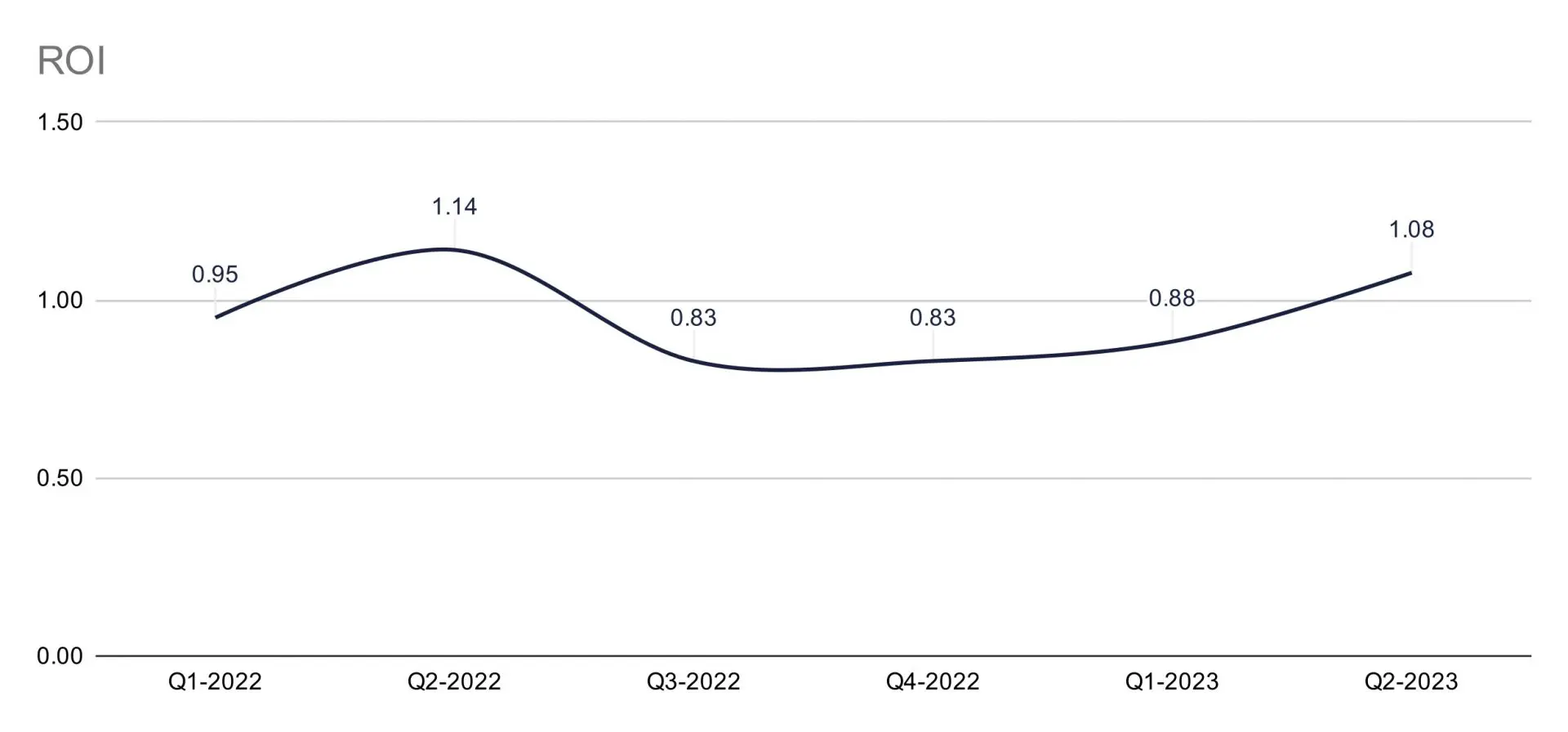

The full integration of Intuendi as a daily platform for demand planning and purchase order management commenced in the second half of 2022. Initially, business analysis showed a higher inventory value due to Casa de las Baterias’ efforts to recover from previous stockouts and lead-time unpredictability. Subsequently, a new inventory level emerged, striking a better balance between product availability targets and a growing catalog. Notably, during H2-2022, the average inventory value rapidly increased, driven by significant purchases and delayed receipts of past orders. In Q2-2023, the inventory value reached a new level, recording a 29% increase compared to Q2-2022 (a period with stockouts and product unavailability), while exhibiting a 12% decrease when compared to H2-2022, which saw the highest peak in inventory value. For a company with an expanding product catalog and a clear strategy to improve product availability, increased inventory levels to meet customer demand are natural. The effort led to a 25% reduction in stockouts when comparing H1-2023 to H1-2022 and a 20% reduction in H1-2023 compared to H2-2022.

“With Intuendi, all the information we need is just a couple of clicks away. It has saved my team and me so much time, and our company a lot of money. We can now focus on the big picture!”

Juan Raúl Gómez, Regional Procurement Manager

-25%

stockouts vs H1-2022

+18%

ROI vs H2-2022

Together, we effectively managed the company’s growth and triumphed over supply chain challenges. This collaborative effort, combining the expertise of our teams with the insights and capabilities of Intuendi AI, proved instrumental in navigating uncertain times, ensuring sustainable growth, and optimizing supply chain management.