In the world of retail and e-commerce, stock availability is the quiet backbone of your entire operation. It all comes down to a simple, powerful promise: having the right product, in the right place, at the right time to meet your customer’s demand. When you get this right, you see an almost immediate lift in sales and customer loyalty. Get it wrong, and you risk not just a lost sale, but real damage to your brand’s reputation. This guide is your roadmap to understanding what stock availability really means, the challenges involved, and the actionable strategies you can use to master it.

What is Stock Availability and Why is It So Important?

Let’s keep it simple. Stock availability is the measure of your business’s ability to fulfill a customer order immediately from the inventory you have on hand. It’s the answer to the question, “Can I buy this right now?” And the answer to that question is far more important than many businesses realize.

Its impact is felt across the board. First and foremost, there’s customer satisfaction. In an age of instant gratification, customers expect what they want without delays. A seamless purchase creates a positive experience that keeps them coming back.

This directly ties into sales and revenue. High availability prevents lost sales from stockouts. Every time a customer sees “out of stock,” that’s potential revenue walking out the door, likely straight to a competitor. Being consistently in stock protects your income stream. Then there’s your brand reputation. A business that’s reliable and always has what people need builds a deep sense of trustworthiness. You become the go-to source. Finally, good stock management creates operational efficiency. It cuts down on the chaos of last-minute rush orders and streamlines the entire fulfillment process, saving you time, money, and a lot of headaches.

The Core Challenge: Balancing Overstocking vs. Understocking

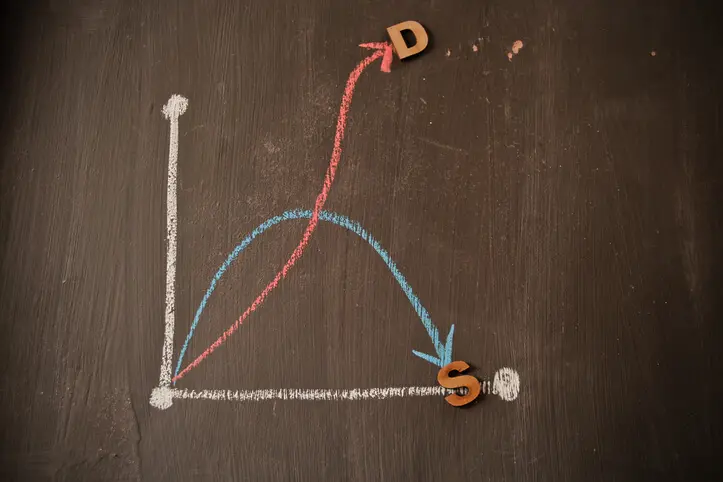

Managing stock availability is a constant balancing act. The goal is to find that “Goldilocks” level of inventory—not too much, not too little, but just right. Leaning too far in either direction creates its own set of expensive problems.

The Risks of Understocking (Stockouts)

Not having enough inventory is the most visible failure. The consequences are immediate and painful. Stockouts lead directly to lost sales. The customer wanted to give you their money, but you couldn’t take it. This creates frustration, and a frustrated customer is very likely to head straight to Google to find a competitor who can meet their needs. Over time, repeated stockouts will seriously damage your brand loyalty. Why would a customer rely on you if you’re always out of what they need? You might also get hit with extra costs, like paying for expensive expedited shipping to replenish stock quickly and appease disappointed customers.

The Risks of Overstocking (Excess Inventory)

On the flip side, having too much inventory is a quieter but equally dangerous problem. The costs are often hidden. First, you have increased carrying costs. This includes the money spent on warehouse space, insurance, and the labor needed to manage all that extra product. All that excess inventory also means you have a ton of capital tied up. That’s money that could be invested in marketing, new product development, or other growth areas. And then there’s the risk of product obsolescence or spoilage. For tech, fashion, or food, that unsold inventory can quickly become worthless, leading to massive write-offs and a direct hit to your profits. It’s the stuff that ends up in the “warehouse graveyard”—that dusty corner where good capital goes to die.

Key Factors That Influence Stock Availability

Stock availability doesn’t just happen in a vacuum. It’s the end result of several interconnected factors pulling in different directions. Understanding these forces is the first step toward getting them under control.

Demand Forecasting and Market Dynamics

How well you predict what your customers will want to buy is probably the biggest influencer of all. This involves looking at historical sales data to spot patterns, but also accounting for seasonality (like swimsuits in summer), emerging market trends, and, crucially, the impact of your own marketing. A big sale or a viral social media post can create a sudden demand spike that will wipe out your inventory if you’re not prepared for it.

Supply Chain Performance

This covers all the external variables that can throw a wrench in your plans. Supplier reliability is a huge one. If your supplier is consistently late, your stock levels will be unpredictable. You also have to consider manufacturing lead times—how long it takes to actually get your product made—and shipping and logistics delays. As we’ve all seen in recent years, major supply chain disruptions can happen unexpectedly, making a resilient supply network more important than ever.

Internal Inventory Policies

Sometimes, the call is coming from inside the house. Your own company’s rules and strategies directly impact your stock levels. This includes things like your reorder points (the stock level that triggers a new order), your safety stock levels (the extra inventory you keep on hand as a buffer), and the overarching inventory model you choose. For instance, a Just-in-Time model aims to keep inventory extremely lean, while a Just-in-Case model prioritizes having plenty of buffer stock for uncertainty.

Actionable Strategies to Improve Stock Availability

Improving stock availability isn’t about finding one magic bullet. It requires a proactive, multi-faceted approach. Think of these strategies as a toolkit; when used together, they create a much more resilient and responsive inventory system.

1. Enhance Your Demand Forecasting

Guessing is not a strategy. To get better at predicting demand, you need to use the tools at your disposal. Modern software can analyze historical sales data to identify complex patterns you might miss. It’s also vital to foster collaboration between your teams. Your sales and marketing folks need to be talking to your inventory team so that everyone is aware of upcoming promotions that could impact demand. Breaking down those internal silos is a game-changer.

2. Optimize Your Inventory Control

This is about the hands-on management of your stock. Set dynamic reorder points that automatically trigger a purchase order when stock hits a certain level. Take the time to properly calculate and maintain your safety stock to protect against surprise demand spikes or shipping delays. It’s also incredibly valuable to conduct regular inventory audits, like cycle counting (checking a small subset of inventory regularly) to ensure your data is always accurate without having to shut down your whole operation for a full count.

3. Strengthen Supplier Relationships

Your suppliers aren’t just vendors; they are partners in your success. Build strong relationships with them through clear and constant communication. When they know what you need and you understand their constraints, everyone wins. It’s also wise to diversify your supplier base where possible. Relying on a single source for a critical product is a huge risk. A broader network gives you flexibility when things go wrong.

4. Leverage Technology and Automation

Frankly, trying to manage a modern inventory system with a spreadsheet is asking for trouble. Technology is your superpower here. An Inventory Management System (IMS) or a full ERP gives you real-time visibility into stock levels across all your channels and locations. Automation can handle tedious tasks like sending reorder notifications and even generating purchase orders, freeing up your team to focus on more strategic work and providing the data you need to make smarter decisions.

How to Measure Stock Availability: Key Metrics to Track

To improve your stock availability, you have to be able to measure it. Key Performance Indicators (KPIs) are how you keep score and find areas that need work. There are a few essential metrics everyone should track.

- In-Stock Rate: This is the most direct measure. It’s the percentage of your items that are available for sale when a customer wants to buy them. A high rate means you’re meeting demand well.

- Order Fill Rate: This metric looks at the percentage of customer orders you can ship completely from your existing stock, without any backorders or cancellations. It’s a great indicator of customer experience.

- Inventory Turnover Ratio: This measures how many times your inventory is sold and replaced over a set period. A healthy, balanced ratio suggests you’re managing stock efficiently, not letting it sit for too long.

Turning Stock Availability into a Competitive Advantage

At the end of the day, managing stock availability is far more than just a logistical task—it’s a strategic imperative. It’s a careful balance between meeting customer demand and maintaining financial health. By combining accurate forecasting, smart inventory policies, strong supplier partnerships, and modern technology, any business can slash costs, boost sales, and build the kind of customer loyalty that lasts. In today’s crowded market, excellent stock availability isn’t just good practice; it’s a powerful competitive weapon.